Ultra-high strength steels with excellent cryogenic temp. toughness

A temperature range and tensile strength technology, applied in the production field of the steel plate, can solve problems such as hydrogen-induced cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

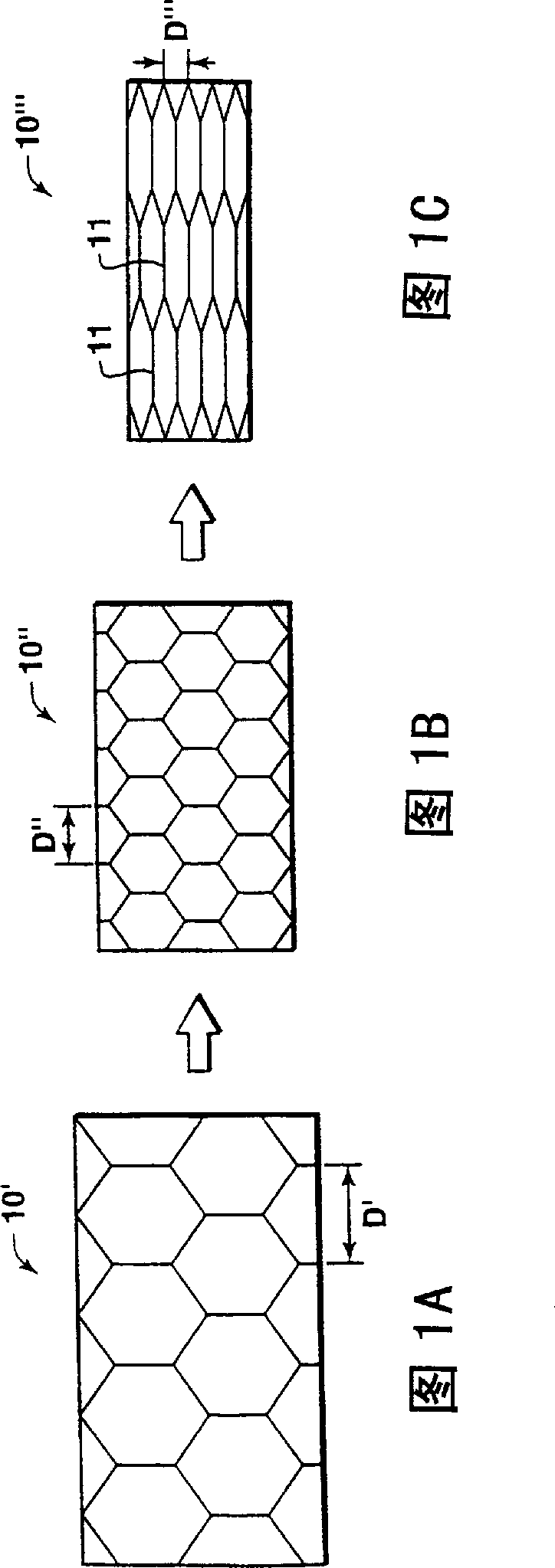

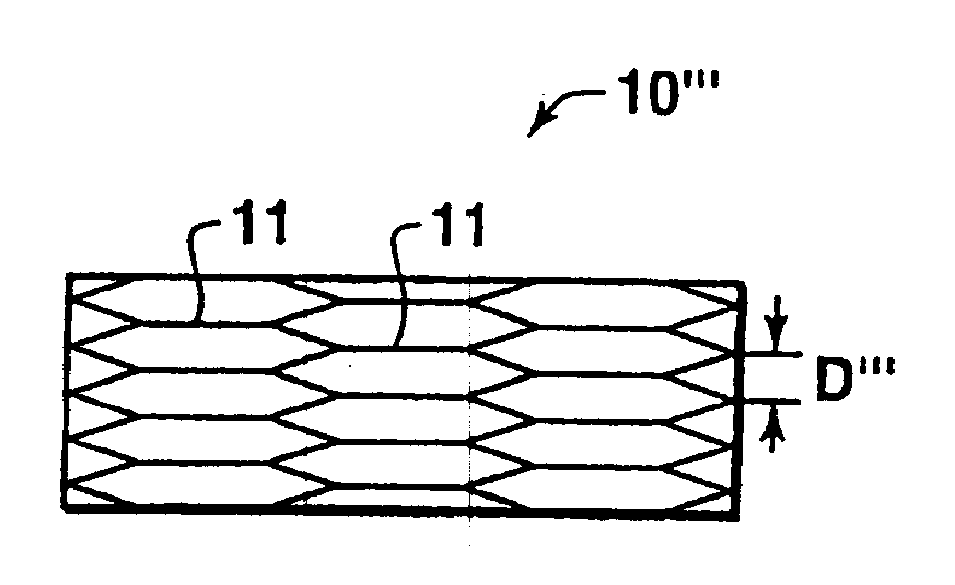

Image

Examples

Embodiment Construction

[0018] The present invention relates to the development of a new type of HSLA steel satisfying the above requirements. The basis of the present invention is to produce intrinsic toughening and microstructure toughening through a new combination of chemical composition and treatment method of steel, thereby reducing DBTT and improving toughness under the condition of high tensile strength. Intrinsic toughening is achieved by a proper balance of important alloying elements in the steel, which is described in detail in this specification. The microstructure is toughened by obtaining a very small equivalent grain size and forming fine-grained martensite and / or lower bainite plates in small bundles with an average size much smaller than prior austenite grains article to achieve. In addition, in the present invention, the strength and toughness of the martensite / bainite microstructure during tempering can be achieved by utilizing fine copper precipitates and dispersion strengthenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com