Anode catalyst for direct methanol fuel battery and method for making same

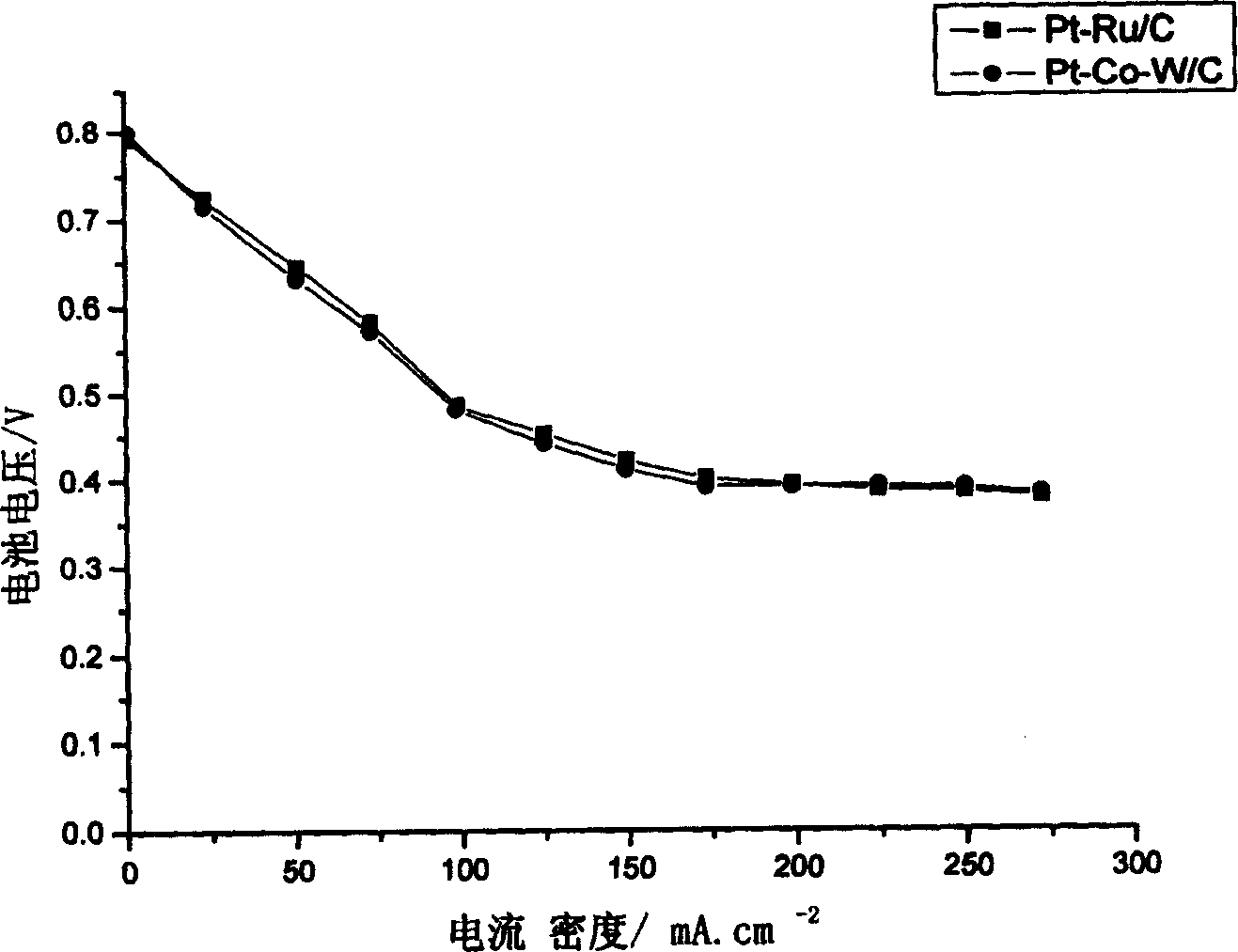

A methanol fuel cell and catalyst technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of expensive catalysts, easy poisoning of catalysts, and high price, and achieve strong anti-CO poisoning ability, The effect of stable product quality and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

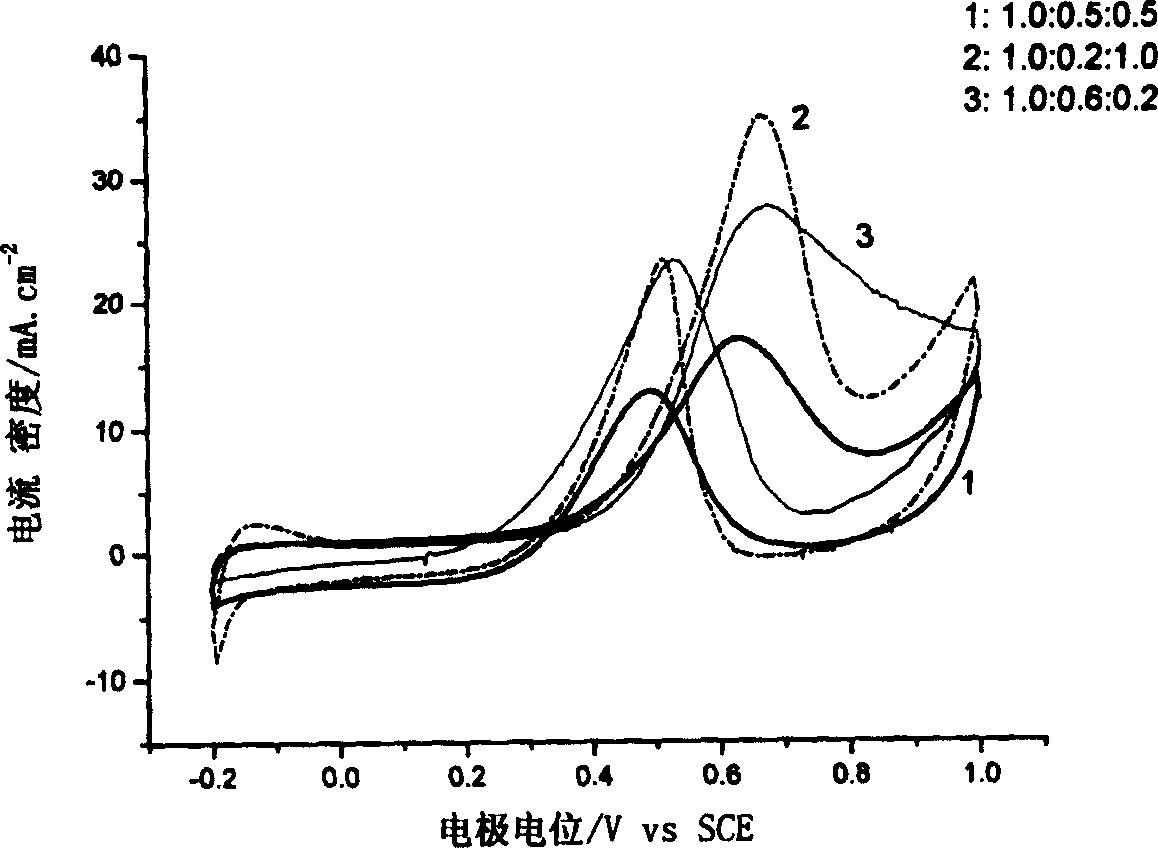

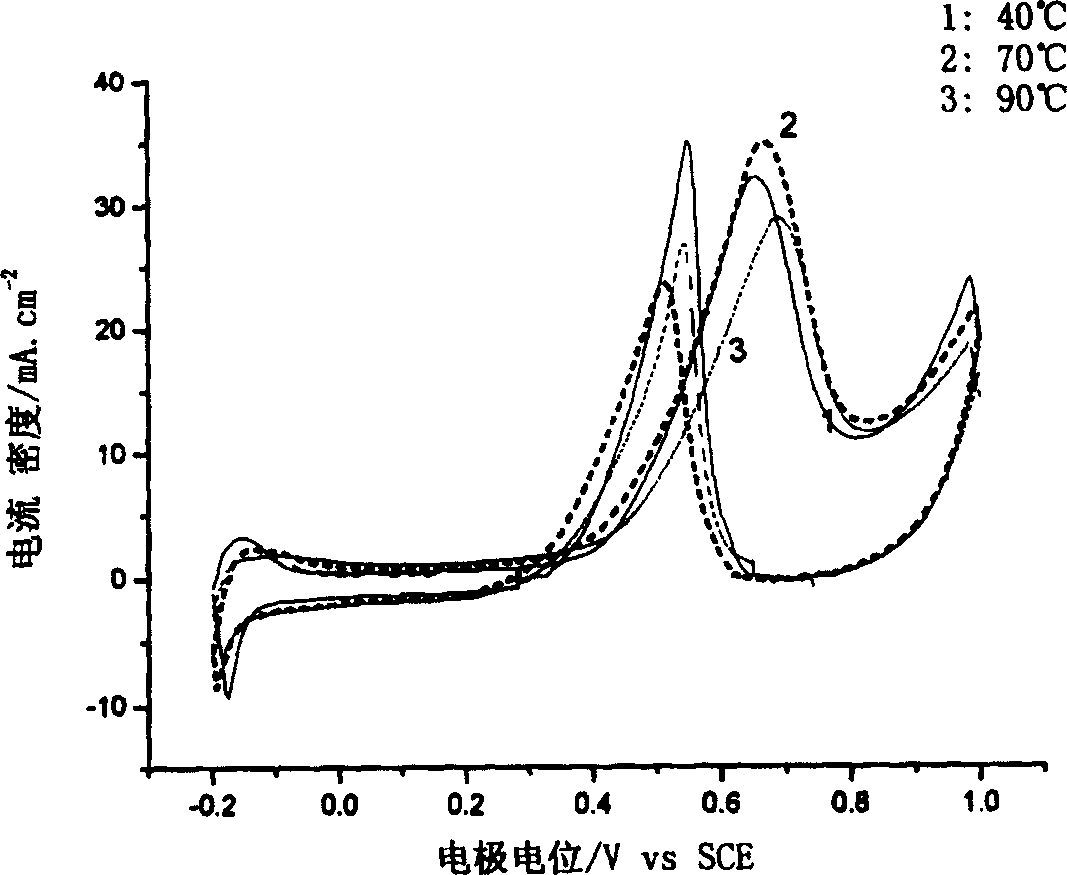

Embodiment 1

[0033] Take 100mg of Vulcan XC-72 carbon black, put it into 200ml of isopropanol and deionized water solution with a molar ratio of 1.0:1.0, mix it, and disperse it by ultrasonic vibration at 70°C for 30min until the system becomes ink-like. Then, according to the prepared catalyst Pt: Co: W metal atom molar ratio is Pt: Co: W=1.0: 0.2: 1.0, adding concentration successively is the chloroplatinic acid solution 5.070g, 5wt% CoCl 2 Solution 0.0932g, 5wt% Na 2 WO 4 646mg of the solution was continuously stirred with a stirrer at 70°C for 1.5h. The pH of the system was adjusted to 10 with sodium bicarbonate solution. Then add formaldehyde solution drop by drop until the metal elements are completely reduced. The reduction reaction time is 2.5 hours. Rinse with deionized water and filter with suction until the system does not contain chloride ions, and then put it in a vacuum drying oven at 120 ° C. Dry in vacuum for 8h. The dried product is cooled and taken out, passed through...

Embodiment 2

[0037] Take 100mg of Vulcan XC-72 carbon black, put it into 200ml of isopropanol and deionized water solution with a molar ratio of 1.0:2.5, mix it, and disperse it with ultrasonic vibration at 70°C for 40min until the system becomes ink-like. Then, according to the prepared catalyst, the molar ratio of metal atoms is Pt: Co: W=1.0: 0.6: 0.2. Adding the concentration successively is the chloroplatinic acid solution 2.9600g, 5wt% CoCl 2 Solution 0.1632g, 5wt% Na 2 WO 4 The solution was 75.4mg, and it was continuously stirred with a stirrer at 70°C for 0.5h. The pH of the system was adjusted to 11 with sodium bicarbonate solution. Then add formaldehyde solution drop by drop until the metal elements are completely reduced. The reduction reaction time is 1 hour. Rinse with deionized water and filter with suction until the system does not contain chloride ions, and then put it in a vacuum drying oven at 80°C. Vacuum dried for 24h. The dried product was cooled and taken out, pas...

Embodiment 3

[0040] Take 100mg of Vulcan XC-72 carbon black, put it into 200ml of isopropanol and deionized water solution with a molar ratio of 1.0:4.0, mix, and disperse with ultrasonic vibration at 70°C for 50min until the system becomes ink-like. Then, according to the standard that metal atomic ratio is Pt in the prepared catalyst: Co: W=1.0: 0.5: 0.5, add the CoCl that concentration is the chloroplatinic acid solution 9.68g of 1wt%, 5wt% successively 2 0.4550g solution, 5wt% Na 2 WO 4 616.5 mg of the solution was continuously stirred with a stirrer for 2.5 h at 70°C. The pH of the system was adjusted to 10 with sodium bicarbonate solution. Then add formaldehyde solution drop by drop until the metal elements are completely reduced. The reduction reaction time is 3 hours. Rinse and filter with a large amount of deionized water until the system does not contain chloride ions, and then put it in a vacuum drying oven at 140 Dry under vacuum for 1 h. The dried product was cooled and ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com