Method for preparing carbon-supported nano Pt-M fuel cell catalyst

A fuel cell and catalyst technology, applied in the field of catalysis, can solve the problems of low adsorption rate, difficult control of particle and dispersion, and high platinum loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The 19.5gPt and 10.1gRu Add one or two of methanol, ethanol, propylene glycol, glycerol, ethylene glycol, and polyvinyl alcohol to dissolve and combine to ensure that the metal concentration is between 1-15mol / L, and then add 0.02-0.8mol of phosphoric acid or lemon acid, at a temperature of 25–60 Ultrasonic 10–20min under the condition; add to 118.4g -5–20 In the carrier carbon, at -5–20 Stir and adsorb for 24–36 hours, dehydrate to constant weight by microwave; add deionized water to slurry, add 29.6–592 mL of methanol, formaldehyde, formic acid, sodium borohydride, and hydrazine hydrate with a concentration of 0.01–5 mol / L under stirring One or both solutions are reduced and warmed to 50–100 ; Filtration, washing the catalyst repeatedly with deionized water, after 80–110 Microwave dehydration and drying to obtain a loading of 20wt% electrocatalyst.

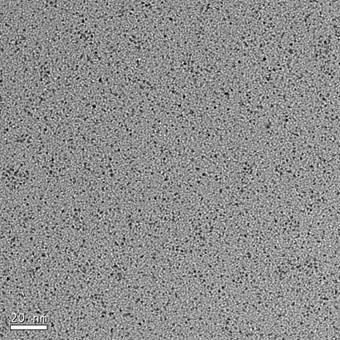

[0026] figure 1 The transmission electron microscope (TEM) photo of the Pt-Ru alloy nanoparticles prepa...

Embodiment 2

[0029] The 19.5gPt and 5.3gPd Add one or two of methanol, ethanol, propylene glycol, glycerol, ethylene glycol, and polyvinyl alcohol to dissolve and combine to ensure that the metal concentration is between 1-15mol / L, and add 0.015-0.6mol of phosphoric acid or lemon acid, at a temperature of 25–60 Ultrasonic 10–20min under the condition; add to 99.2g -5–20 In the carrier carbon, at -5–20 Stir and adsorb for 24–36 hours, dehydrate to constant weight by microwave; after adding deionized water to slurry, add 24.8–496 mL of methanol, formaldehyde, formic acid, sodium borohydride, and hydrazine hydrate with a concentration of 0.01–5 mol / L under stirring One or both solutions are reduced and warmed to 50–100 ; Filtration, washing the catalyst repeatedly with deionized water, after 80–110 Microwave dehydration and drying to obtain a loading of 20wt% electrocatalyst.

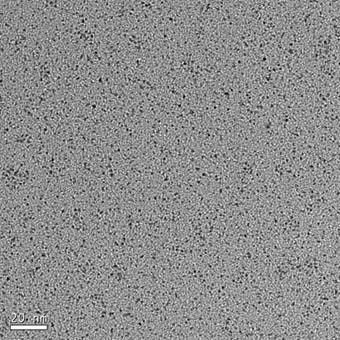

[0030] The average particle size of the Pt-Pd alloy nanoparticles prepared in this example is 2.2nm, ...

Embodiment 3

[0033] The 19.5gPt and of Add one or two of methanol, ethanol, propylene glycol, glycerol, ethylene glycol, and polyvinyl alcohol to dissolve and combine to ensure that the metal concentration is between 1-15mol / L, and then add 0.02-0.8mol of phosphoric acid or lemon acid, at a temperature of 25–60 Ultrasonic 10–20min under the condition; add to 101.2g -5–20 In the carrier carbon, at -5–20 Stir and adsorb for 24–36 hours, dehydrate to constant weight by microwave; add deionized water to slurry, add 25.3–506 mL of methanol, formaldehyde, formic acid, sodium borohydride, and hydrazine hydrate with a concentration of 0.01–5 mol / L under stirring One or both solutions are reduced and warmed to -50–100 ; Filtration, washing the catalyst repeatedly with deionized water, after 80–110 Microwave dehydration and drying to obtain a loading of 20wt% electrocatalyst.

[0034] Prepared in this example The average particle size of the alloy nanoparticles is 1.9nm, the dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com