Anion and cation co-doped PbWO4 crystal and its growth method

An anion and cation, growth method technology, applied in high light yield anion and cation double-doped lead tungstate crystals, high light yield lead tungstate crystals and their growth fields, can solve the problems of slow luminescence, achieve high yield, reduce The effect of cracking and growth temperature field stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. The purity is both 99.99% high-purity PbO and WO 3 The powder is precisely prepared according to the stoichiometric ratio, and is melted in a platinum crucible to make a highly dense PWO polycrystalline ingot;

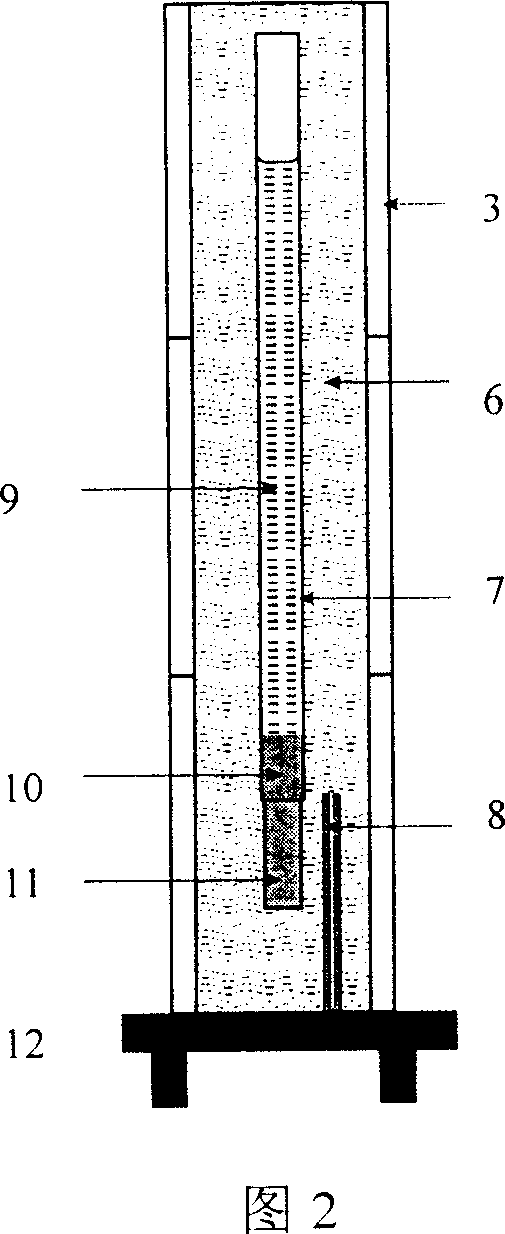

[0030] 2. A φ25×400mm crucible is made of a single-layer platinum sheet with a thickness of 0.12mm;

[0031] 3. A single crystal with orientation and a size of φ24.5×65mm is used as the seed crystal;

[0032] 4. With PbF 2 and Y 2 o 3 As a dopant, 700ppm (at%) PbF was added after loading the raw material into a platinum crucible 2 and 300ppm(at%) of Y 2 o 3Dopant, then install the seed crystal and close the crucible;

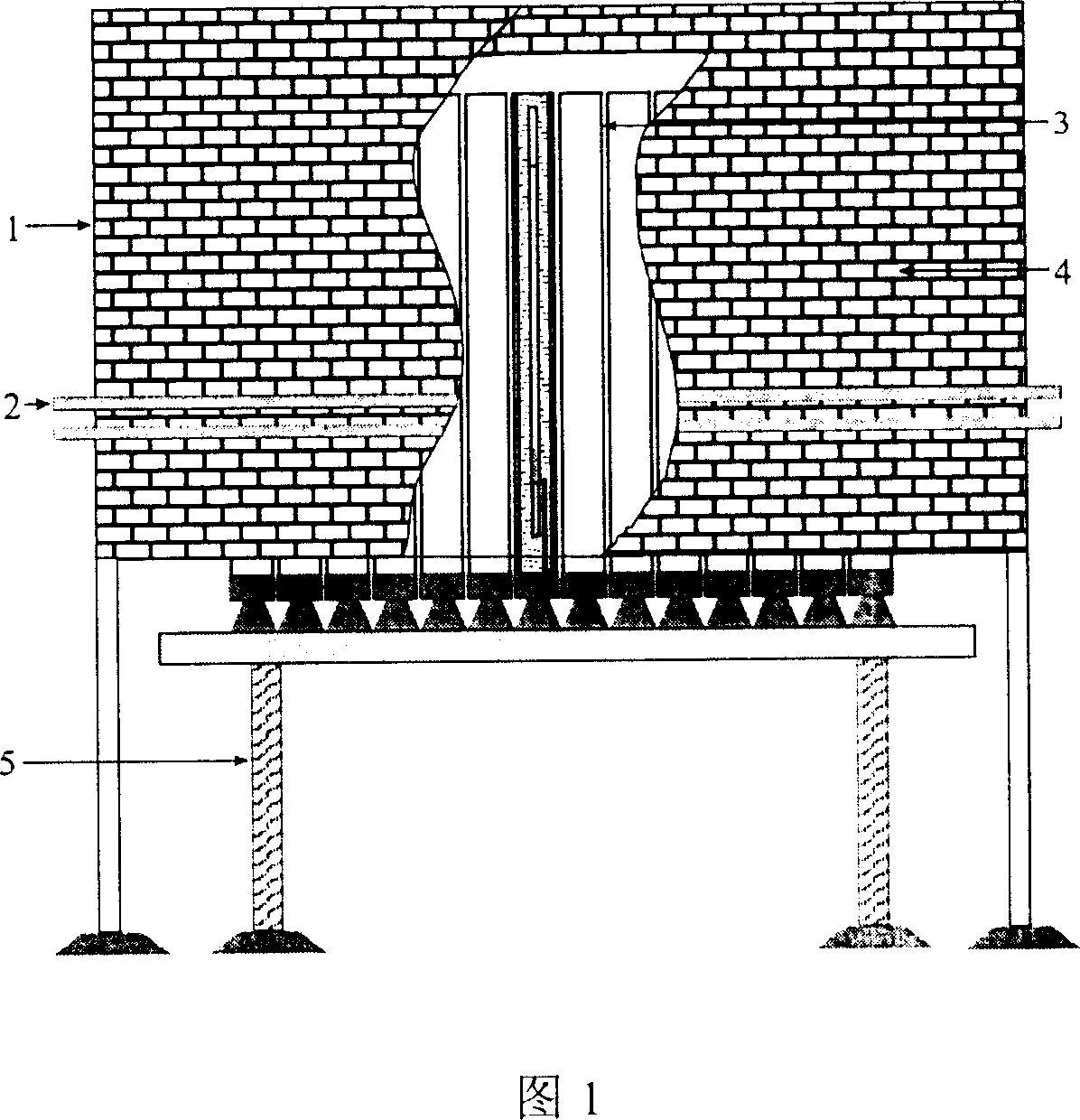

[0033] 5. Put the platinum crucible with raw material and seed crystal into the downcomer;

[0034] 6. Raise the temperature of the furnace to 1150°C at a rate of 80°C / hour, keep it warm for 4 hours, and then gradually raise the downcomer. After all the raw materials and the top of the seed crystal are melted, keep it warm for 2 hours,...

Embodiment 2

[0038] 1. High-purity PbO and WO after roasting 3 Precisely formulated according to stoichiometry, and made into high-density PWO polycrystalline ingot after melting;

[0039] 2. Use a square platinum crucible with a thickness of 0.14mm and a size of 25×25×450mm;

[0040] 3. A single crystal with an orientation of and a size of 24.5×24.5×65 mm is used as a seed crystal.

[0041] 4. With BaF 2 and Y 2 o 3 As a dopant, add 900ppm (at%) BaF after loading the polycrystalline ingot into a platinum crucible 2 and 100ppm(at%) of Y 2 o 3 Dopant, then install the seed crystal and close the crucible.

[0042] 5. Control the temperature of the furnace to 1200°C, lower the downcomer at a rate of 0.4mm / hour, and the growth temperature gradient is 20-30°C / cm;

[0043] 6. The grown crystals can be processed directly without post-treatment.

[0044] 7. In this example, 6 crystals were grown in one furnace.

[0045] 8. Other conditions are the same as example 1.

Embodiment 3

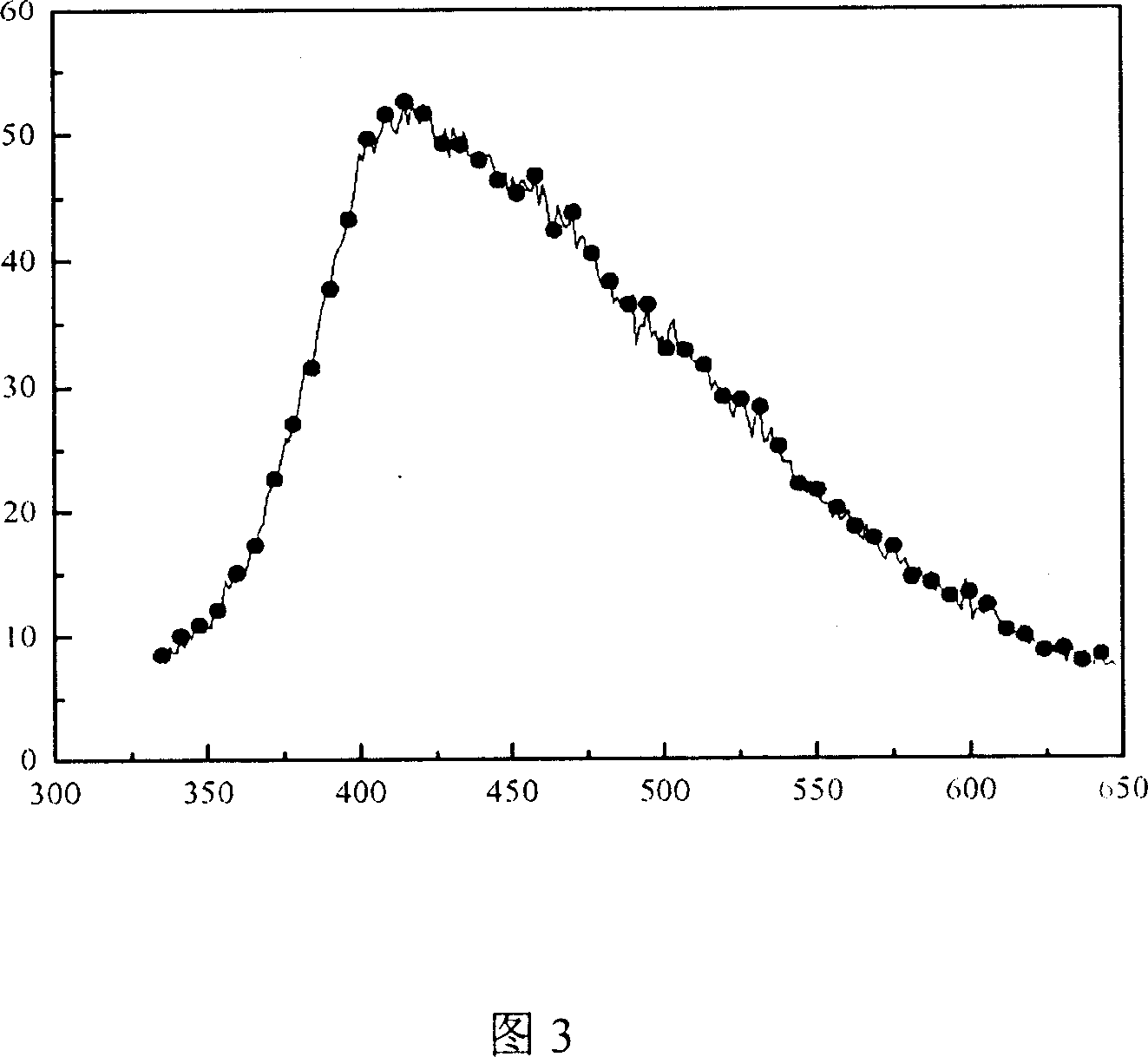

[0047] In this example, the temperature of the furnace is controlled at 1250° C., the crucibles are 25×25×475 mm and φ25×475 mm, and 28 crystals are grown in one furnace, and other conditions are the same as in Example 1 or 2. The light yield of the grown double-doped crystals is compared with that of pure PWO crystals are listed in Table 1.

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com