Czochralski method growth process of sodium nitrate monocrystalline

A technology of sodium nitrate and pulling method, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc. It can solve the problem of unsatisfactory crystal integrity, purity and crystallization degree, high temperature field and growth process control requirements, and difficult Obtaining large-sized complete single crystals and other problems, achieving the effects of reducing crystal pollution, simple and convenient process, and small thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

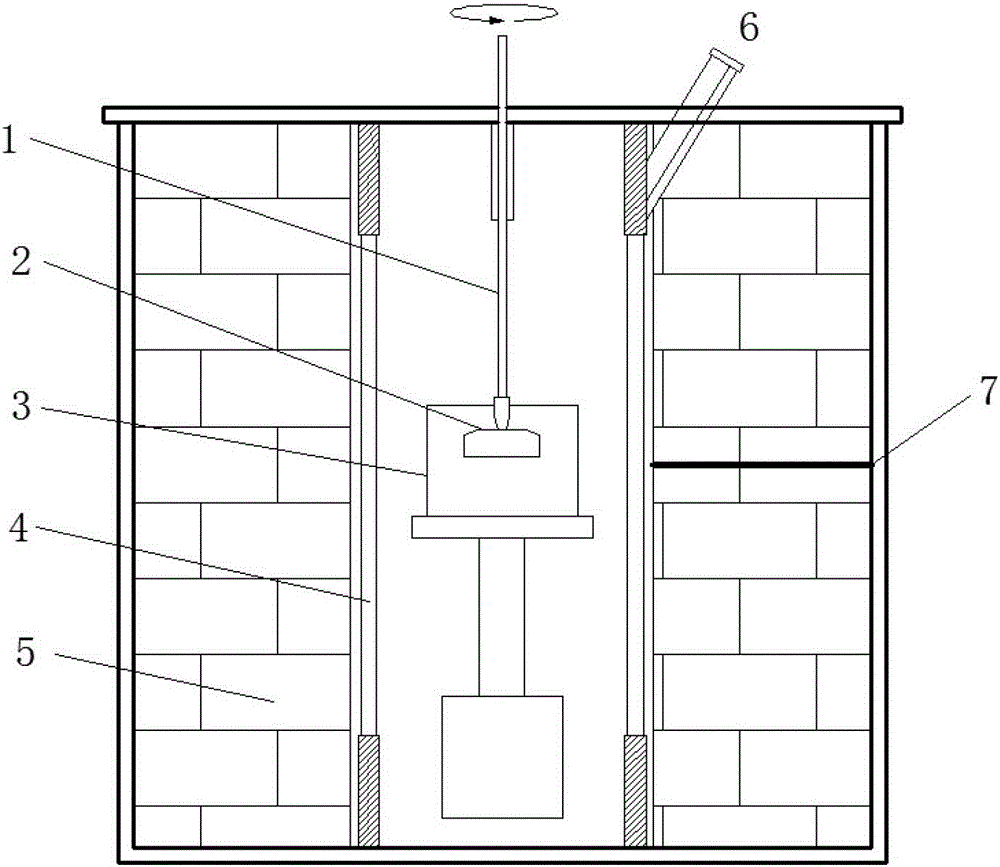

Method used

Image

Examples

Embodiment 1

[0037] (1) Using spectrally pure sodium nitrate (≥99.99%) as a raw material, after roasting at 120° C. for 2 hours to remove water, charge in a drying oven;

[0038] (2) Use size Φ50×60mm 3, a cylindrical platinum crucible with a wall thickness of 2.0mm, put the raw materials into the crucible, then put the crucible into the pulling furnace, raise the furnace temperature to 350°C after 2 hours, and then keep it warm for 2 hours to completely melt the raw materials. Slowly lower the furnace temperature and gradually shake down the seed rod, the size of the seed crystal is 3×3×80mm 3 , not targeted. When the furnace temperature is controlled at 310°C, the automatic pulling device is turned on to start crystal growth, the pulling rate is 2.0mm / h, and the temperature gradient of the growth interface is 20°C / cm;

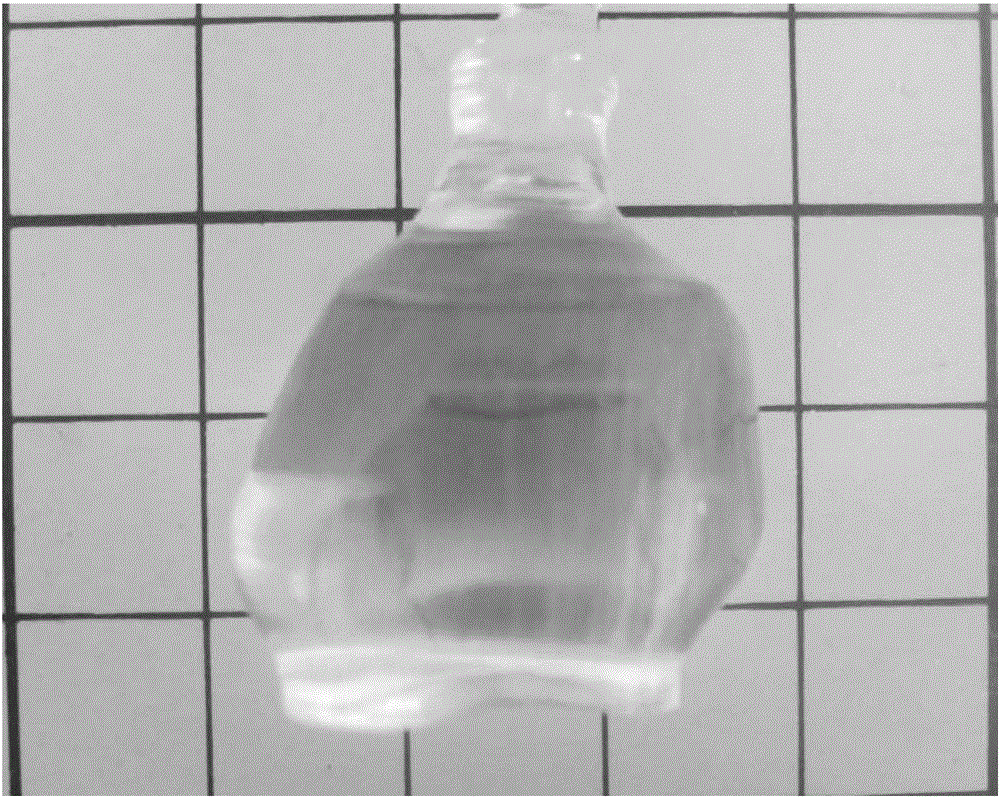

[0039] (3) Slowly adjust the heating power, and after completing the shouldering and equal diameter processes, lift the crystal out of the melt. Cool the furnace body ...

Embodiment 2

[0041] (1) Using spectroscopically pure sodium nitrate (≥99.99%) as a raw material, after dewatering by roasting at 150°C for 1 hour, charging in a drying oven;

[0042] (2) Use size Φ50×60mm 3 , A cylindrical platinum crucible with a wall thickness of 2.0mm, put the raw materials into the crucible, then put the crucible into the pulling furnace, raise the furnace temperature to 380°C after 3 hours, and then keep it warm for 2 hours to completely melt the raw materials. Slowly lower the furnace temperature and gradually shake down the seed rod, the size of the seed crystal is 4×4×70mm 3 , with an orientation of . When the furnace temperature is controlled at 310°C, the automatic pulling device is turned on to start crystal growth, the pulling rate is 2.0mm / h, and the temperature gradient of the growth interface is 20°C / cm;

[0043] (3) Slowly adjust the heating power, and after completing the shouldering and equal diameter processes, lift the crystal out of the melt. Cool t...

Embodiment 3

[0045] (1) Using spectroscopically pure sodium nitrate (≥99.99%) as a raw material, after dewatering by roasting at 100°C for 3 hours, charging in a drying oven;

[0046] (2) Use size Φ50×60mm 3 , a cylindrical platinum crucible with a wall thickness of 2.0mm, put the raw materials into the crucible, then put the crucible into the pulling furnace, raise the furnace temperature to 360°C after 3 hours, and then keep it warm for 2 hours to completely melt the raw materials. Slowly lower the furnace temperature and gradually shake down the seed rod, the size of the seed crystal is 5×5×50mm 3 , with an orientation of . When the furnace temperature is controlled at 320° C., the automatic pulling device is turned on to start crystal growth, the pulling rate is 3.0 mm / h, the growth interface temperature gradient is 25° C. / cm, and other process operations are the same as in Example 2 (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com