Method for preparing bipolar film by self-assembling technology

A bipolar membrane and anion membrane technology, applied in the field of preparation of ion-exchange composite membranes, can solve problems such as no reports on the technology, and achieve the effects of improving the speed of dissociating water, improving work efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] Embodiment 2. 4.5meq / g anion resin powder with ion exchange capacity and 3.6meq / g cationic resin powder with ion exchange capacity are mixed with polyvinyl alcohol according to the mass ratio of 1: 1 respectively, and stir at 90 ℃ to make polyethylene Alcohol dissolved, anion and cation resin powder dispersed evenly. The membrane solution was left at room temperature for 24 h to remove air bubbles. Spread the negative membrane solution on the prepared flat glass, and let it stand at room temperature for 24 hours to remove air bubbles. The aqueous solution of polyacrylic acid with a mass concentration of 25% is diluted with absolute ethanol to a mass concentration of 2.265%. Place the anion film prepared above in this solution for 30 seconds, the negatively charged polyacrylic acid anion is adsorbed on the surface by the positively charged anion film according to a certain structure, take out the film, and let it stand at room temperature for 20 minutes to evaporate the...

Embodiment 3

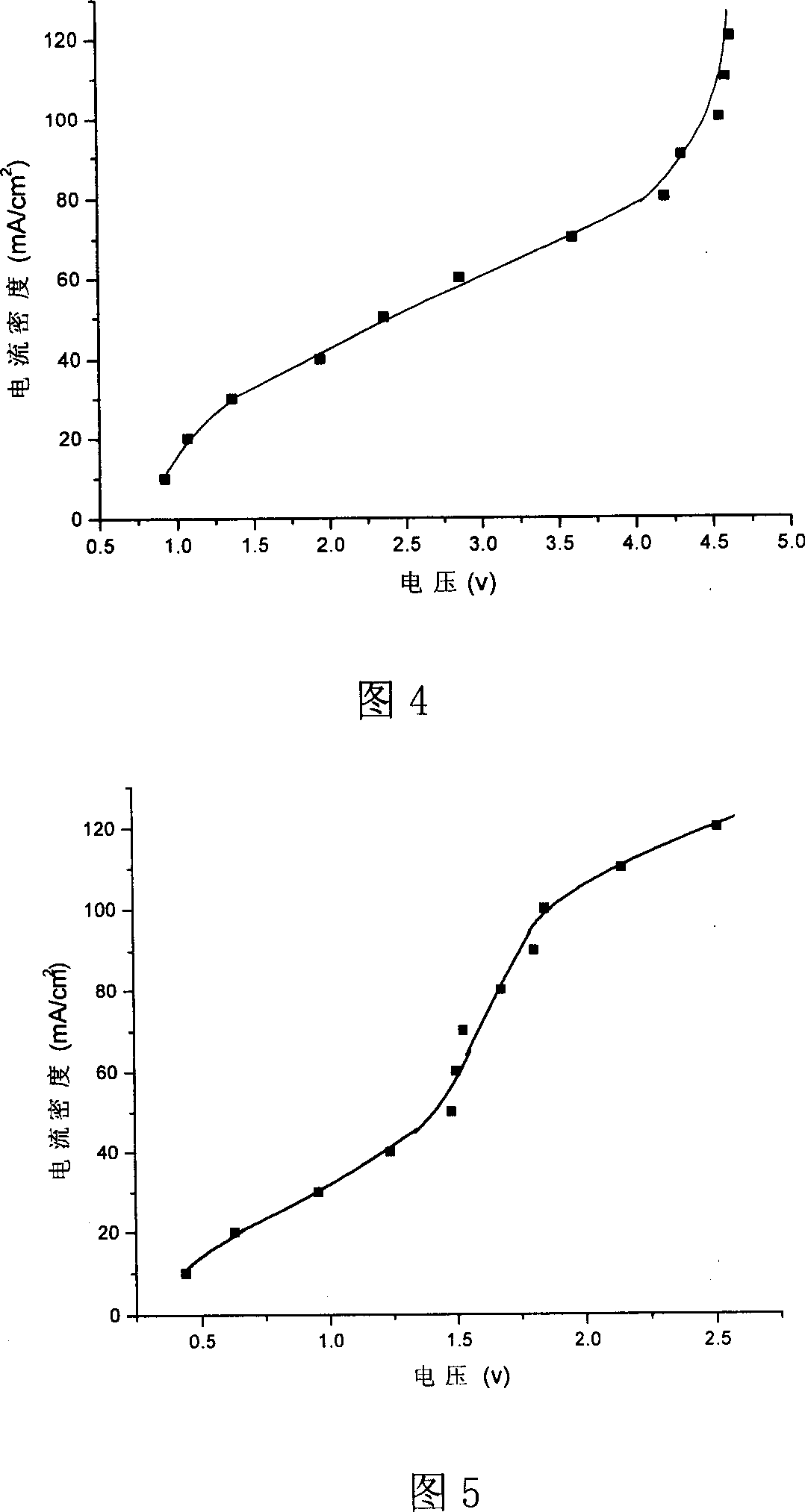

[0047] Embodiment 3. Using the steps of Example 2, the self-assembly time is 60s to prepare bipolar membrane 2#. By means of the device in Fig. 3, a bipolar membrane voltage-current density curve is obtained. As shown in Figure 6.

[0048] It can be concluded from Figure 6 that when the voltage is 1.25V, the current density is 88.9mA / cm2; when the current density is 100mA / cm2, the voltage is 1.28V.

Embodiment 4

[0049] Example 4: Mix the anion resin powder with an ion exchange capacity of 4.5meq / g and the cationic resin powder with an ion exchange capacity of 3.6meq / g with polyvinyl alcohol in a mass ratio of 0.5:1, and stir at 90°C to make the polyethylene Alcohol dissolved, anion and cation resin powder dispersed evenly. The membrane solution was left at room temperature for 24 h to remove air bubbles. Spread the negative membrane solution on the prepared flat glass, and let it stand at room temperature for 24 hours to remove air bubbles. The aqueous solution of polyacrylic acid with a mass concentration of 25% is diluted with absolute ethanol to a mass concentration of 2.265%. Place the anion film prepared above in this solution for 30 seconds, the negatively charged polyacrylic acid anion is adsorbed on the surface by the positively charged anion film according to a certain structure, take out the film, and let it stand at room temperature for 20 minutes to evaporate the solvent....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com