Front body for lithographic printing plate

A lithographic printing plate and precursor technology, which is applied in the field of lithographic printing plate precursors, can solve problems such as increased pollution and achieve excellent printing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

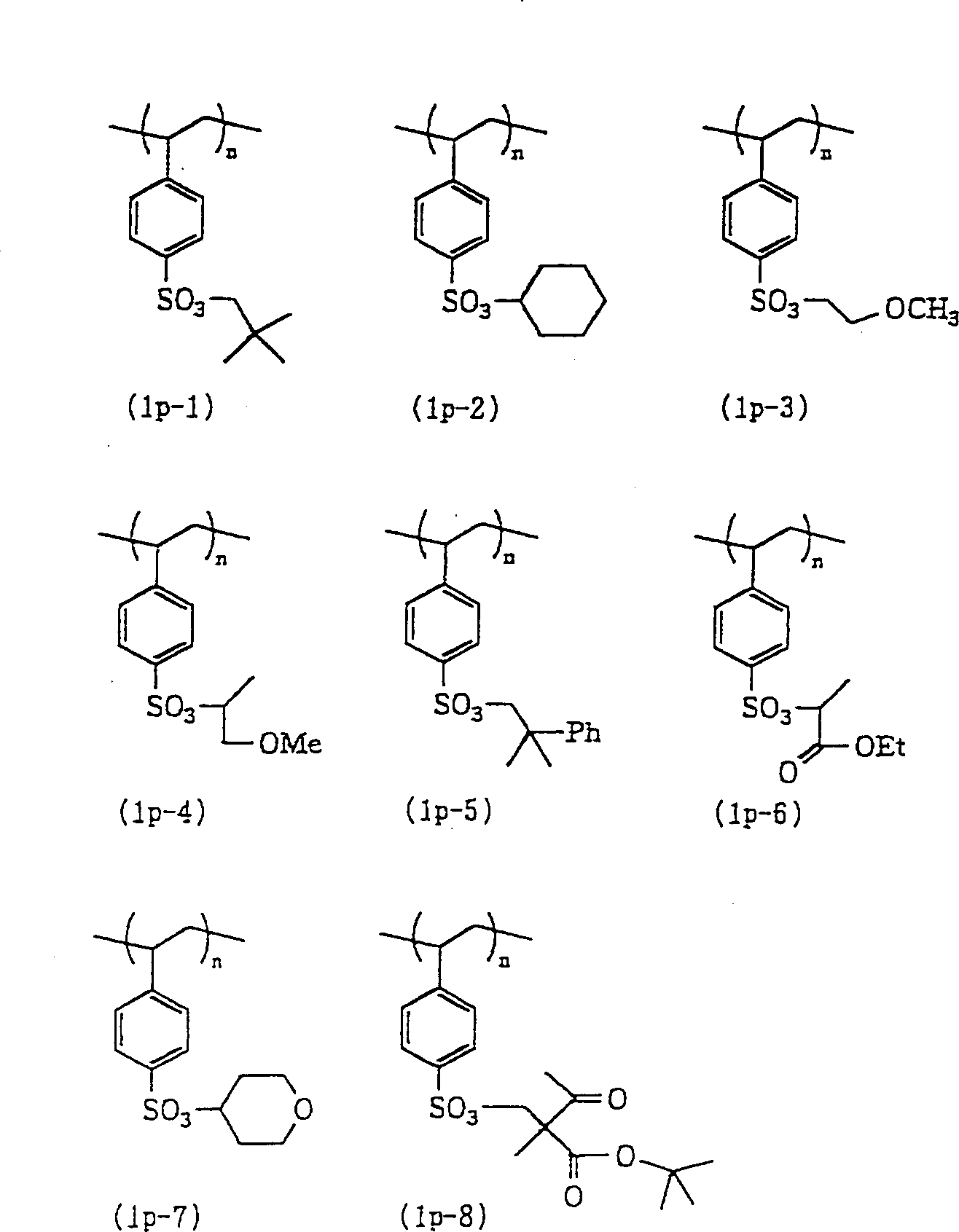

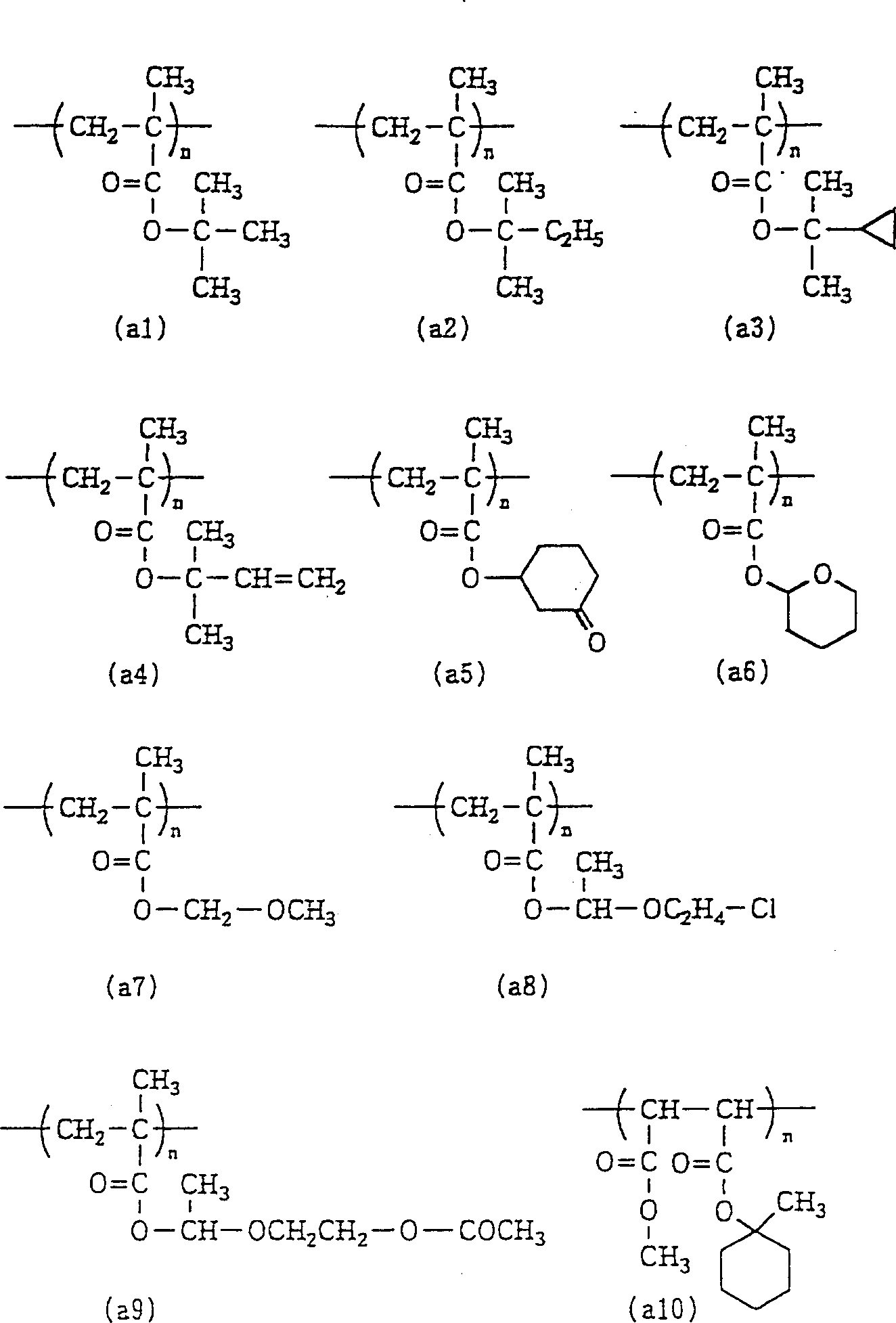

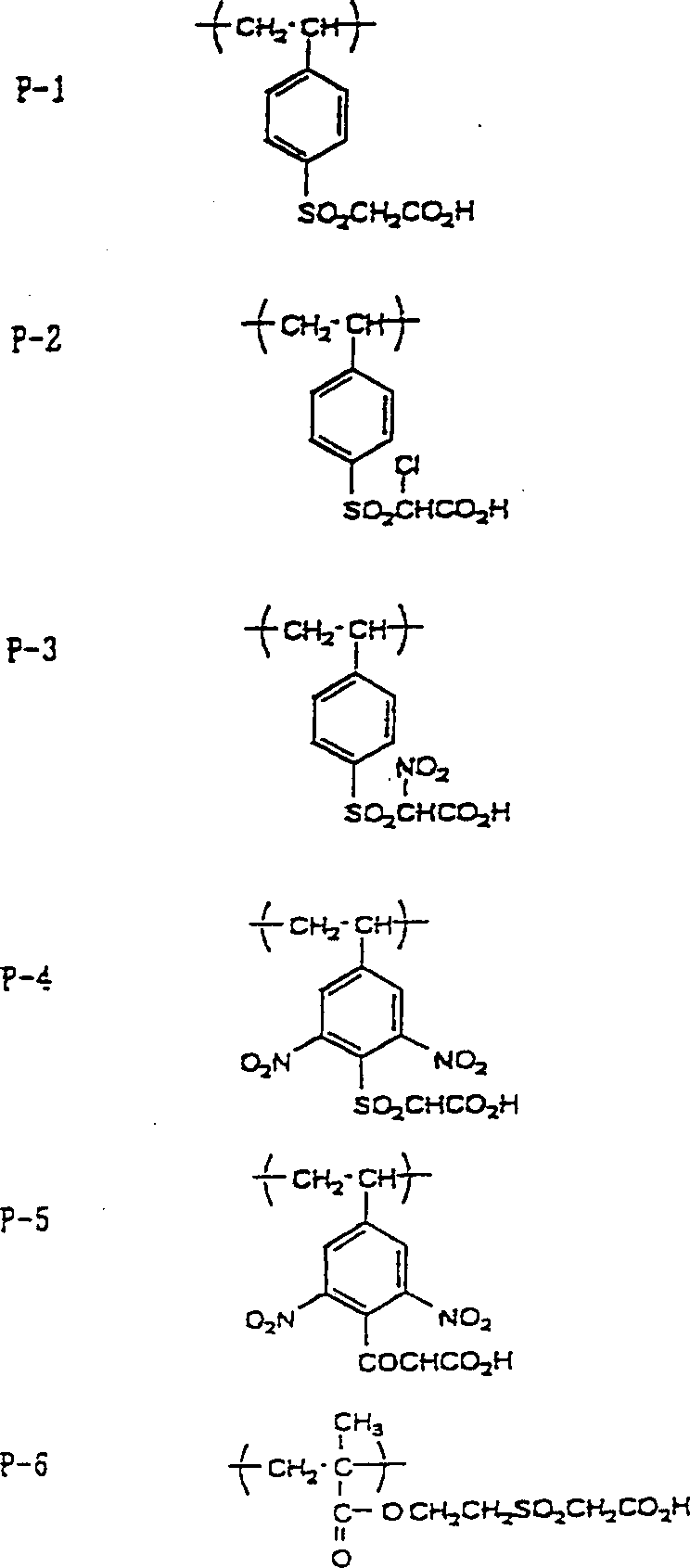

Method used

Image

Examples

Embodiment

[0151] The present invention is further described in the following examples, but the present invention is not limited by these examples. The synthetic embodiment (1) of polymkeric substance of the present invention: (synthetic hydrophilic macromonomer and amide macromonomer)

[0152] 30 g of acrylamide and 3.8 g of 3-mercaptopropionic acid were dissolved in 70 g of ethanol. Under a nitrogen atmosphere, the obtained solution was heated to 60°C. An additional 300 mg of AIBN was added to the solution. Then, the reaction mixture was reacted for 6 hours. After the reaction was terminated, the formed white precipitate was filtered off and washed sufficiently with methanol to obtain 30.8 g of a carboxylic acid-terminated prepolymer.

[0153] 20 g of the obtained prepolymer were redissolved in 62 g of dimethyl sulfoxide. To the solution were added 6.71 g of glycidyl methacrylate, 504 mg of N,N-dimethyldodecylamine (catalyst), and 62.4 g of hydroquinone (polymerization initiator). ...

Embodiment I-1-I-3

[0158] Embodiment I-1-I-3 (preparation method containing sol-gel carrier)

[0159] Use a nylon brush and a water suspension of 400-mesh pumice stone to dehair the aluminum plate with a thickness of 0.30mm, and then wash it thoroughly with water. The depilated aluminum plate was etched by immersing it in 100% aqueous sodium hydroxide solution at 70° C. for 60 seconds, washed with running water, neutralized and washed with 20 wt % nitric acid, and then washed with water. The etched aluminum plate is electrolytically roughened with a sinusoidal current in 1wt% nitric acid aqueous solution, and the anodizing current is 160 coulomb / dm 2 , VA is 12.7V. Surface roughness measurement of the roughened aluminum plate. The result was 0.6 µm (Ra). Afterwards, the aluminum plate was dipped again in 30 wt % sulfuric acid aqueous solution, and decontaminated at 55° C. for 2 minutes. Put the decontaminated aluminum plate in 20wt% sulfuric acid aqueous solution at 2A / dm 2 Anodizing treatm...

Embodiment I

[0167]By incorporating heat-meltable hydrophobic particles, photothermal conversion materials, etc. into the cross-linked hydrophilic layer, the surface of the cross-linked hydrophilic layer will be endowed with hydrophobicity when subjected to heat or light radiation, allowing the laser The beam is scanned and exposed in a short time to form an image. Thus, it is possible to provide a negative-working lithographic printing plate precursor which can be subjected to a simple aqueous development treatment for plate production or can be mounted on a printing press without development treatment for plate production. Example II-1-II-3 (positive photosensitive lithographic printing plate precursor) (preparation method containing sol-gel carrier)

[0168] Aluminum carrier substrates were prepared in the same manner as in Examples I-1 to I-3. (cross-linked hydrophilic layer)

[0169] In Examples II-1 to II-3, the following coating solution having the following formulation was applie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com