Thermosensitive polymerized lithographic printing plate

A lithographic printing plate and polymerization technology, which is applied in the field of high printing force, can solve the problems of poor adhesion of the plate base, poor storage stability, poor coating performance, etc., and achieve tough coating and solvent resistance Strong, Graphically Beautiful Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention includes a support and a thermally polymerized layer, wherein the thermally polymerized layer contains a functional polymer binder (A) having structures i and ii that can be polymerized by ethylenically unsaturated groups; The polymer adhesive structure is as follows:

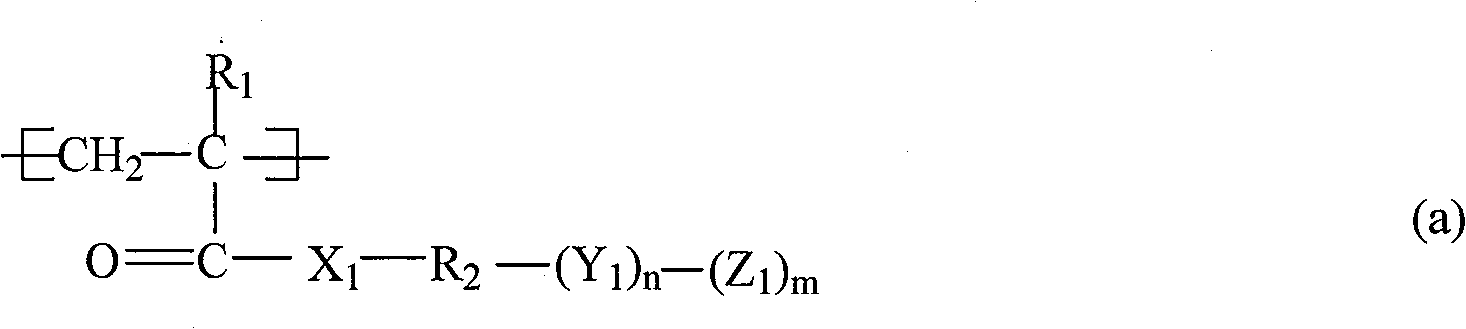

[0040] i has either of the following two structural (a) (b) units:

[0041] (a) Structural unit with alkali solubility

[0042]

[0043] In the formula, X1 represents -O- or -NR3-, R1 represents -H or -CH3, R2 represents a single bond or a divalent organic bond group, Y1 represents an arylene group, n represents 0 or 1, and R3 represents that it can have a hydrogen atom Or an alkyl group, cycloalkyl group, aryl group or aralkyl group of 1-12 carbon atoms in the substituent; Z1 represents a group with an acidic hydrogen atom, and m represents an integer greater than 1;

[0044] (b) Structural unit of alkali-soluble maleimides

[0045]

[0046] Z represents a group having an ...

Embodiment 2

[0068] The present invention includes: a support and a thermopolymerizable layer, wherein the thermopolymerizable layer contains a functional polymer binder (A) having structures i and ii that can be polymerized by ethylenically unsaturated groups. It also contains unsaturated radically polymerizable monomers and oligomers (B), an infrared absorber (C) capable of absorbing IR rays, and at least one compound (D) capable of generating free radicals.

[0069] Functional polymer adhesive (A)

[0070] Functional polymer adhesive (A) has the structure of structure i and ii as follows:

[0071] i has the following two structural units:

[0072] (a) Structural unit with alkali solubility

[0073]

[0074] In the formula, X1 represents -O- or -NR3-, R1 represents -H or -CH3, R2 represents a single bond or a divalent organic bond group, Y1 represents an arylene group, n represents 0 or 1, and R3 represents that it can have a hydrogen atom Or an alkyl group, cycloalkyl group, aryl ...

Synthetic example 1

[0139] Add 20 g of methyl ethyl ketone and 0.18 g of azobisisobutylcyanide to a 250 ml three-necked flask equipped with a stirrer, a reflux tube, and a dropping funnel. Use a hot water bath to heat to 80°C while passing nitrogen protection. Add dropwise a mixture of 20g methyl ethyl ketone, 3.5g N-(4-hydroxybenzene)methacrylamide, 4.5g N-(4-sulfonamidobenzene)maleimide, 4.5g styrene, 3.0g methacrylic acid The solution was mixed, and the dropwise addition was completed in 2 hours. React at constant temperature for 10 hours. After the reaction was completed, 40 g of methanol was added, cooled, added into 2 L of water with stirring, stirred for 1 hour, filtered and dried to obtain 12.98 g of white solid. The weight-average molecular weight (polystyrene standard) of the high molecular weight polymer measured by silica gel permeation chromatography was 45,000.

[0140] Dissolve 10 grams of the high polymer obtained above in 100 grams of propylene glycol monomethyl ether acetate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com