Nickel series rechargeable battery and its producing method

A recharging and battery technology, which is applied in the manufacture of nickel storage batteries, alkaline storage batteries, battery electrodes, etc., can solve the problems of inability to prolong the charge and discharge cycle life, achieve excellent overcharge resistance, improve the utilization rate of active materials, and have high activity The effect of material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

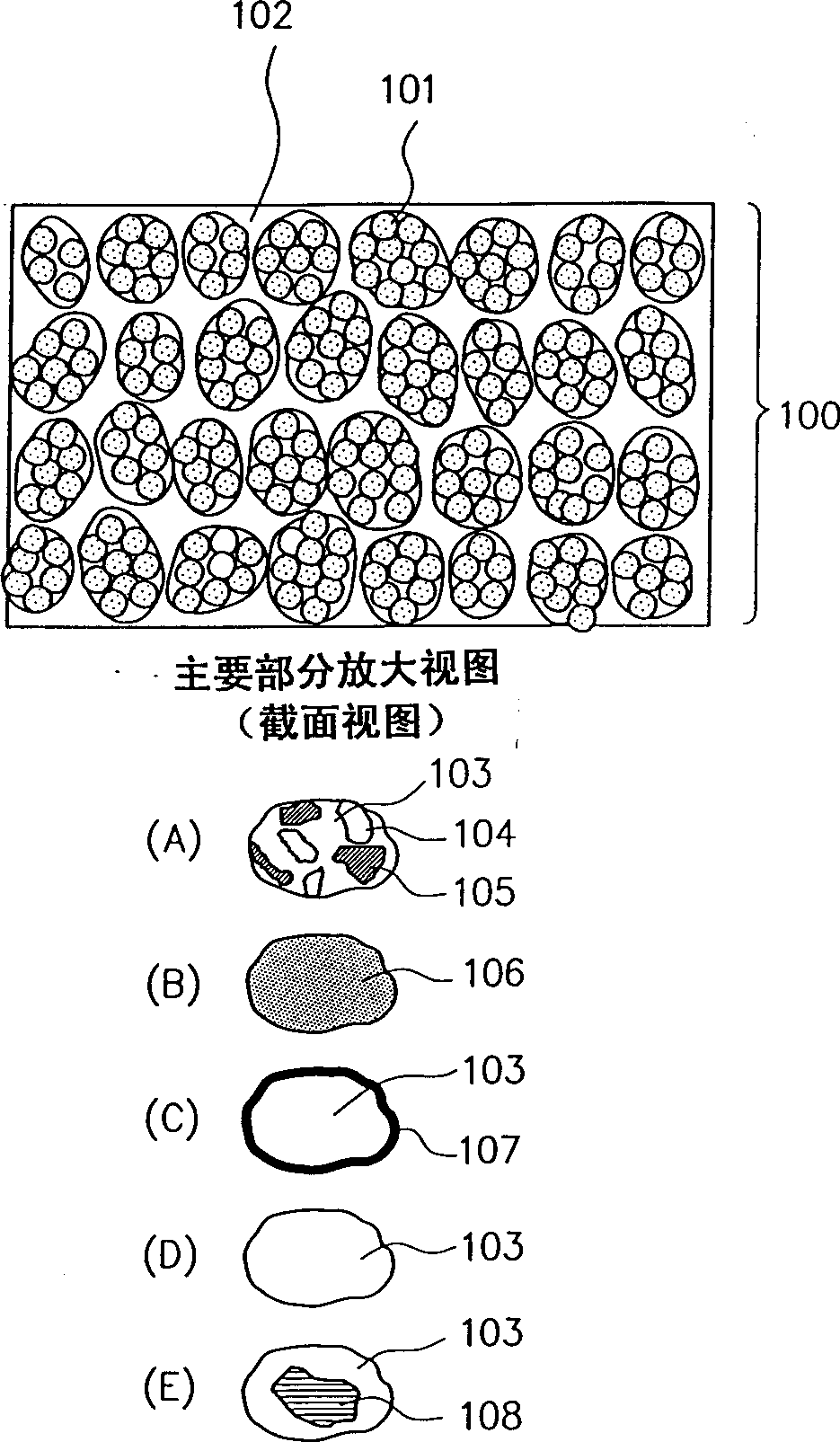

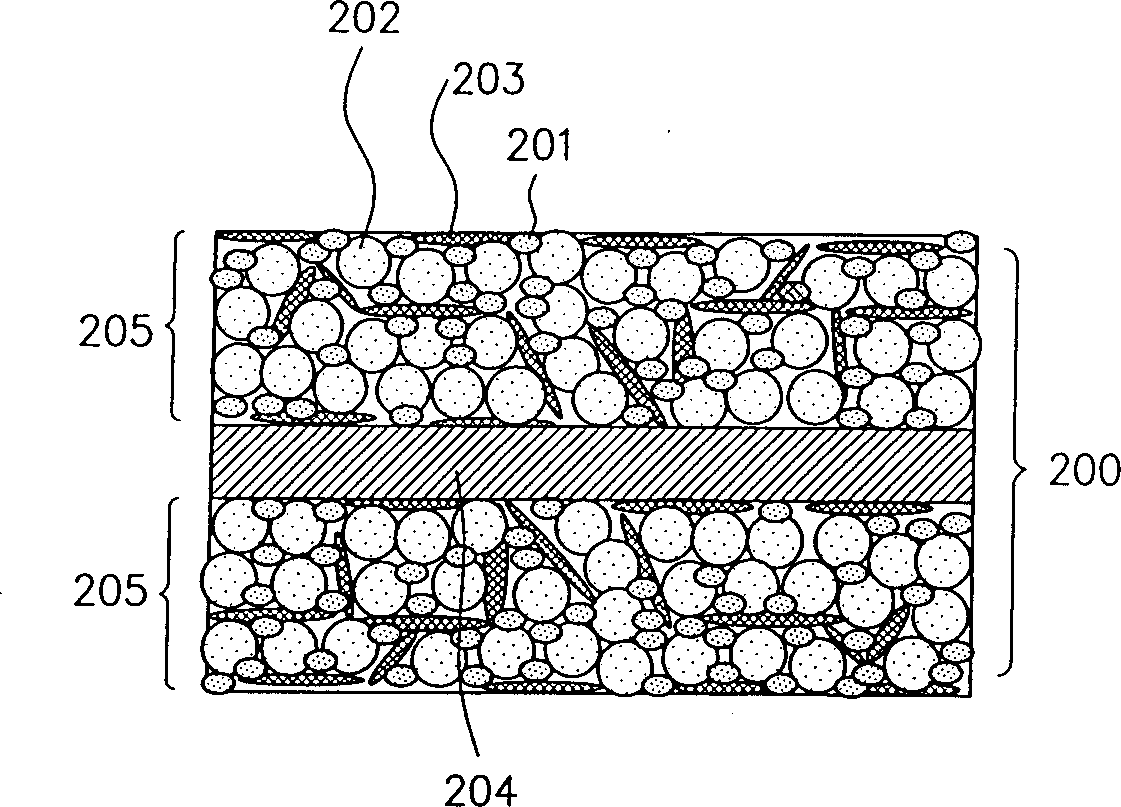

[0154] In this example, the following method was used to prepare the Figure 5 configured spiral-wound cylindrical rechargeable battery.

[0155] 1. Preparation of cathode:

[0156] (1) Preparation of nickel hydroxide powder:

[0157] The powdery nickel hydroxide material as the starting material can be prepared by the usual reaction crystallization method in the following manner.

[0158] Add ammonium sulfate to the specified amount of nickel sulfate aqueous solution. Under the condition of strong stirring, the sodium hydroxide aqueous solution was added dropwise into the nickel sulfate aqueous solution, while controlling its pH value to 11, and the nickel sulfate aqueous solution obtained a kind of precipitation. The resulting precipitate was washed with pure water and dried to obtain nickel hydroxide powder (particles) including spherical particles.

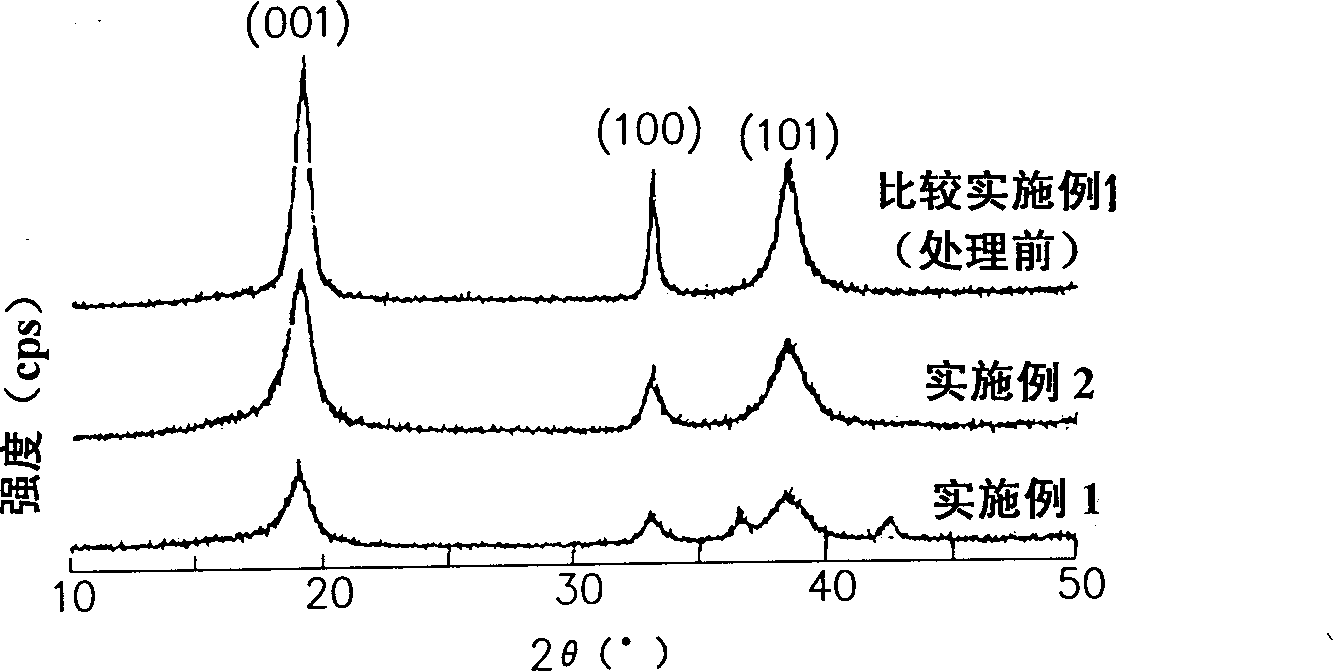

[0159] Use X-ray diffractometer RINT2000 (produced by Kabusiki Kaisha RIGAKU) to the nickel hydroxide powder sample that...

Embodiment 2

[0181] The operation of Example 1 was repeated except that Step 1-(2) and Step 1-(3) in Example 1 were carried out as follows, to obtain a spiral-wound type rechargeable battery.

[0182] Preparation of cathode electrode material:

[0183] The nickel hydroxide powder that obtains in embodiment 1 step 1-(1) is put together with rigid grinding ball and carries out in star ball mill grinding equipment, here, under argon atmosphere, when acceleration is 15G, to nickel hydroxide powder Grinding treatment was performed for 10 minutes to obtain a powder. The resulting powder was subjected to ultrasonic dispersion treatment in pure water, followed by drying to obtain amorphous nickel hydroxide powder (particles).

[0184] Use X-ray diffractometer RINT2000, carry out wide-angle X-ray diffraction analysis to the powder sample of generation, use the Kα-ray of Cu as radiation source, X-ray diffraction figure is shown in image 3 , which appears near the diffraction angle 2θ=19° as a dif...

Embodiment 3

[0201] The operation of Example 1 was repeated except that Step 1-(2) and Step 1-(3) in Example 1 were carried out as described below to obtain a spiral-wound type rechargeable battery.

[0202] Preparation of cathode electrode material:

[0203] 92% by weight of the nickel hydroxide powder obtained in step 1-(1) of Example 1, 6% by weight of cobalt monoxide powder and 2% by weight of yttrium oxide powder were mixed to obtain a powdery mixture . The resulting mixture was placed together with rigid grinding balls in a planetary ball mill where the powdery mixture was subjected to a grinding process for 10 minutes at an acceleration of 15 G in an argon atmosphere to obtain a powder. The resulting powder was subjected to ultrasonic dispersion treatment in pure water, followed by drying to obtain amorphous nickel hydroxide powder (particles) bonded with cobalt monoxide and yttrium oxide.

[0204] Use X-ray diffractometer RINT2000 to carry out wide-angle X-ray diffraction analysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com