Purifying method of semi-conductor gas

A gas and pure gas technology, applied in specific gas purification/separation, chemical instruments and methods, inert gas compounds, etc., can solve problems such as large-scale purification cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

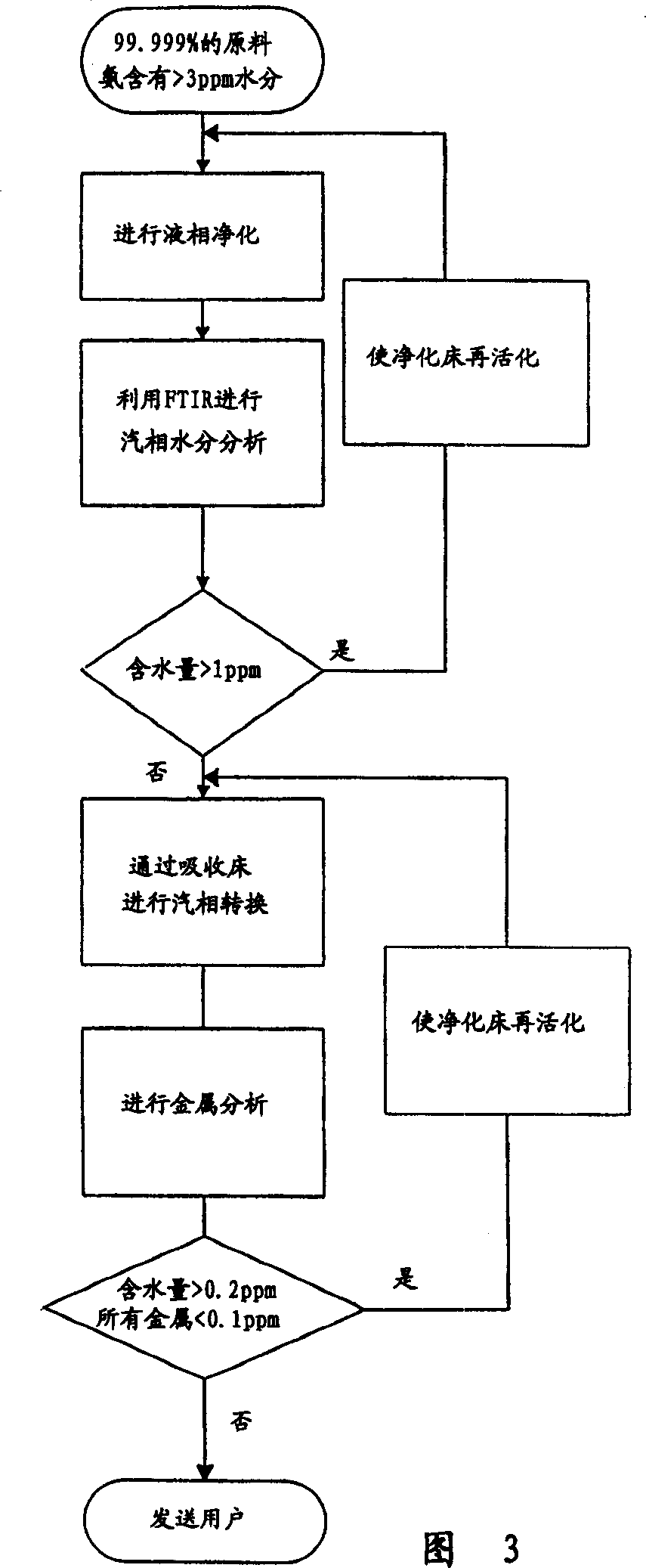

[0033] Figure 4 An example of a batch plant using this purification scheme is shown. The device consists of two unit operations, the first unit operation is a liquid phase switching system and the second unit operation is a vapor phase switching system.

[0034] In the liquid conversion system, raw ammonia is stored in storage tank 410 . The delivery of the liquid raw product is carried out by using a mechanical pump, an inert gas cushion or by means of a head of ammonia. Liquid ammonia is passed through a metering device 412 into an absorption bed 414 which is also provided with a filter layer to trap particles passing through a particulate filter 416 . Bed 414 is a 3A molecular sieve bed in good condition. Measuring devices, such as flow meters, are used to measure liquid flow. The purified product is stored in tank 418. The product is then analyzed to ensure that the moisture concentration in the vapor phase is below about 1 ppm. If the moisture concentration is abov...

Embodiment 2

[0037] A solution for low water content using absorption and steam shift, which can be extended to Figure 5 The continuous mass production system shown. The unit consists of a distillation system 516 and two sets of absorption beds 514 and 518. Raw ammonia is stored in tank 510. Liquid raw product delivery is carried out by using mechanical pumps, inert gas cushions or by means of ammonia head pressure. Liquid ammonia is passed into an absorber bed 514 which also contains a filter layer to trap particles. Bed 514 is a 3A molecular sieve bed in good condition. A measuring device 512, such as a flow meter, is used to measure the flow of fluid. The purified product is then analyzed to ensure that the moisture concentration in the vapor phase is below about 1 ppm. If the moisture concentration is above about 1 ppm, the absorption bed must be regenerated, and the ammonia goes through the process all over again. This ammonia is sent to distillation system 516 if the moisture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com