Process for preparing cathode copper by one-step electrolysis of raw red copper

A technology of purple miscellaneous copper and cathode copper, which is applied in the direction of photographic technology, equipment, photographic auxiliary technology, etc., can solve the problems of long production process, high manufacturing cost, and low copper recovery rate, and achieve simple production method and low manufacturing cost , the effect of high copper recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

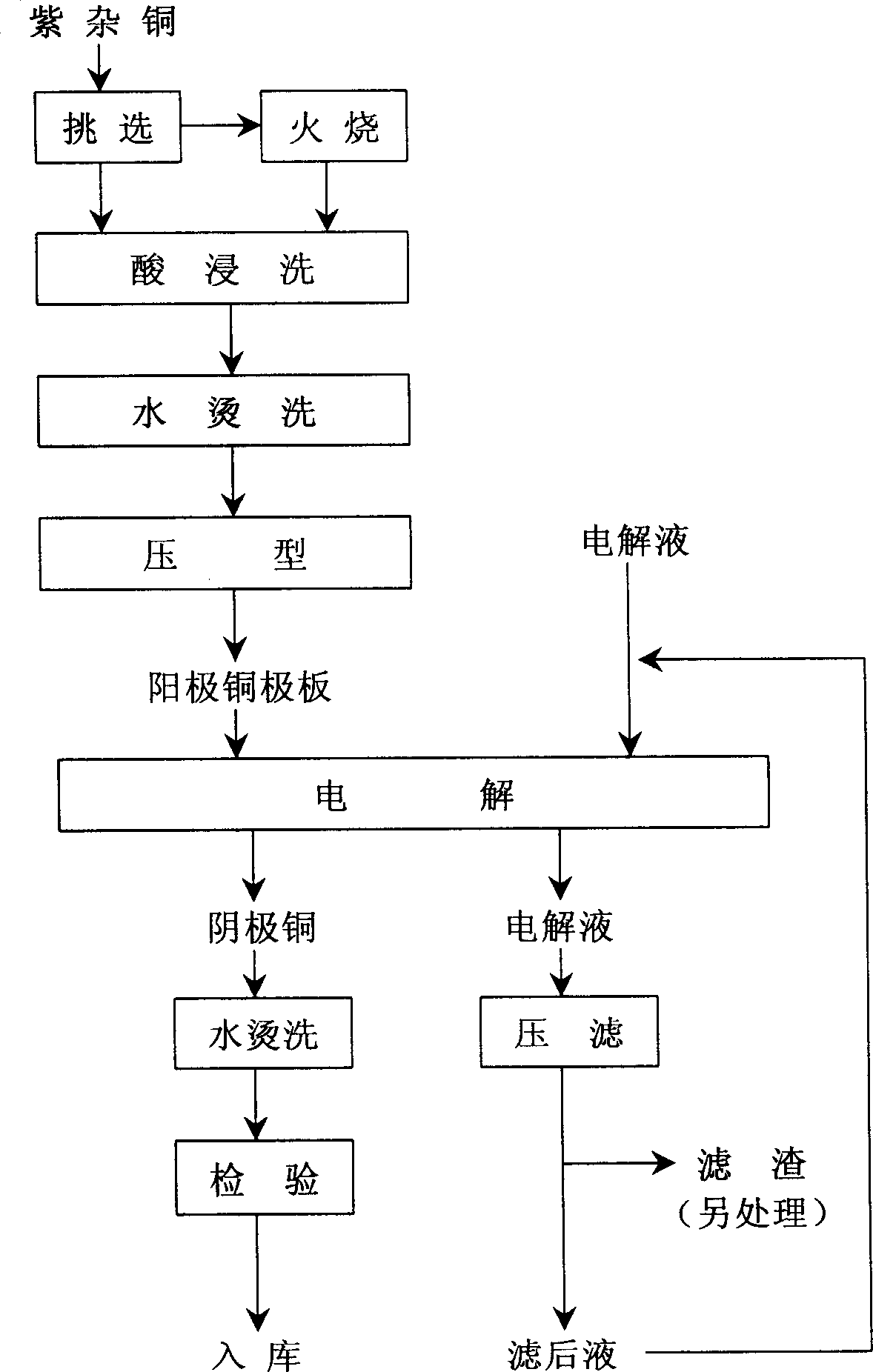

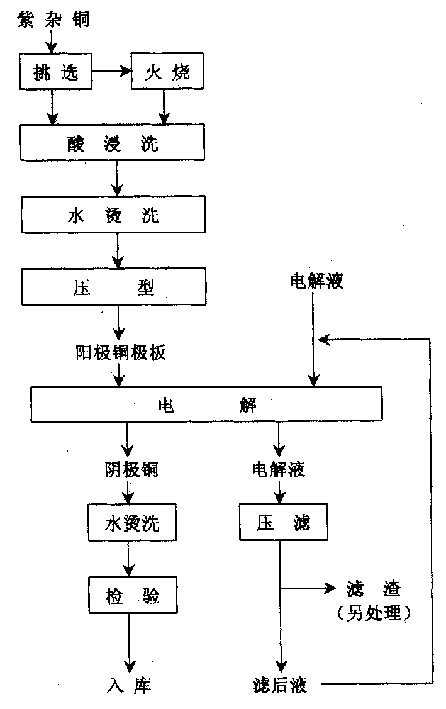

[0008] Use below figure 1 The process flow diagram and examples of the one-step electrolytic production of cathode copper from red copper are shown to illustrate the present invention in detail.

[0009] Studies have shown that the main impurities of red copper are lead and tin, the general content is about 0.50%, in addition, there are a small amount of zinc, lead and some non-metallic impurities, such as plastic, rubber, paint leather and other surface coatings.

[0010] Lead reacts with sulfuric acid during electrolysis to form lead sulfate and lead sulfide, which are insoluble and cover the surface of the anode. Since the present invention uses a red copper anode with a large surface area and a high chemical dissolution rate, the surface of the anode is covered with lead sulfate and lead sulfide, which reduces the speed of chemical dissolution of the red copper and is more conducive to the implementation of the production method of the present invention.

[0011] During e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com