Method for preparing collagen and biological ceramic powder composite material microparticles

A technology of bioceramics and collagen, which is applied in the field of preparing composite materials in the form of particles, can solve the problems of destroying the properties of collagen and tissue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

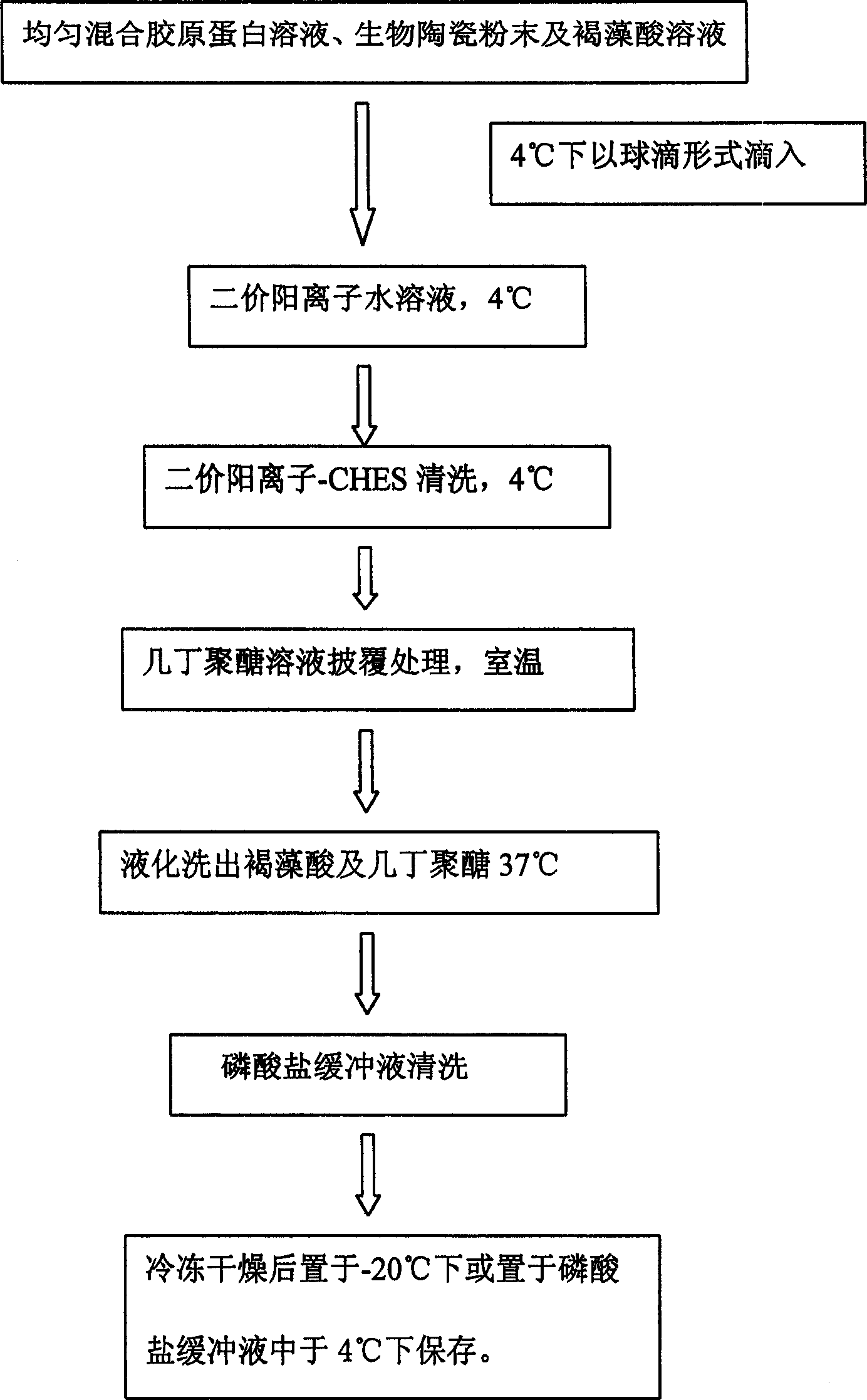

[0030] Please refer to figure 1 As shown, the collagen and bioceramic powder composite particles were prepared according to the following steps:

[0031] 1. Take 6ml of the purified Type I collagen solution (concentration: 6mg / ml), 66.86mg of β-tricalcium phosphate powder, and 1.8ml of alginic acid solution (concentration: 6%) and 1.2 ml of phosphate buffer saline (PBS, phosphate buffersaline), which were thoroughly mixed. Wherein the weight percent ratio of collagen protein and β-tricalcium phosphate is 35 / 65.

[0032] 2. With the air jet-syringe pump extrusion, adjust the nitrogen flow rate to 5ml / min, drop the above mixed solution into calcium chloride (CaCl 2 , 1.5%) gelled into microparticles in aqueous solution. The above process was performed at 4 °C to prevent collagen reorganization.

[0033] 3. The calcium chloride aqueous solution was replaced with Ca-CHES (2-N-cyclohexylaminoethane-sulfuric acid), and the particles were aged in it for 5 minutes for cleaning. I...

Embodiment 2

[0038] The device and steps are as in Example 1, except that in step 3, 0.005w / v% tetrasan solution (prepared with 0.005% lactic acid, pH value = 5.5) is coated for 5 minutes, and the others are the same as in Example 1. A step of.

[0039] The results of this experiment show that more than 95% of the alginic acid has been washed out at 9 hours, and the alginic acid has been almost completely washed out after 12 hours. The structure of the particles was observed with a scanning electron microscope, Figure 3A and 3B When the system is 9 hours, Figure 3C and 3D It is a SEM photo of particle section and surface structure observed at 10,000 times at 24 hours. The experimental results found that after 9 hours, the inside and surface of the particles had a three-dimensional collagen fiber structure, and a small amount of chitosan remained on the surface; after 24 hours, both the inside and the surface of the particles had a three-dimensional collagen fiber structure, and the c...

Embodiment 4

[0041] Device, steps are as embodiment 1, except that in step 2, the flow rate of nitrogen is adjusted to 7.5ml / min and others are the same as embodiment 1. Experimental results show that, like Example 1, the microparticles have a three-dimensional collagen fiber network structure inside and on the surface, and the average particle size of the microparticles is 835±36 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com