Composite nano metal particle-semiconductor medium film and its prepn process and completely optical kerr switch

A technology of metal nanoparticles and composite thin films, applied in optics, nonlinear optics, instruments, etc., can solve problems such as being unable to be received by the detector 8, and achieve a high signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Composite film and its preparation

[0028] (1) The transparent substrate is selected as glass, under high vacuum conditions (vacuum degree is better than 5×10 -5 Pa) Deposit Ba metal film on one side of the glass until the white light transmittance drops to 30%;

[0029] (2) Oxygen gas with a concentration of 99.9% is introduced to oxidize the Ba metal film until the white light transmittance is basically restored to obtain a BaO film;

[0030](3) Depositing a metal Ag film on the surface of the BaO film;

[0031] (4) The film prepared in (3) is sequentially annealed at 120° C. for more than half an hour in vacuum and at 100° C. for more than one hour in the atmosphere.

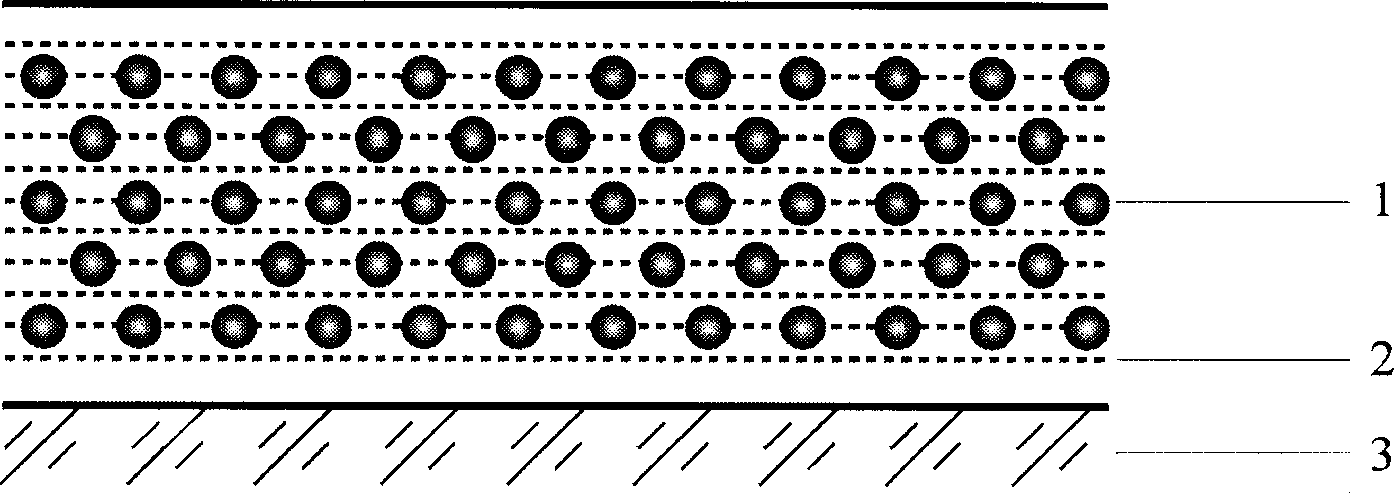

[0032] The schematic diagram of the structure of the prepared Ag-BaO thin film is shown in figure 1 As shown, a semiconductor dielectric film 2 is deposited on one side of the glass substrate 3, specifically a BaO film; the semiconductor dielectric film 2 is embedded with uniformly d...

Embodiment 2

[0033] Embodiment 2: Ultrafast Optical Switch and Optical Logic Device

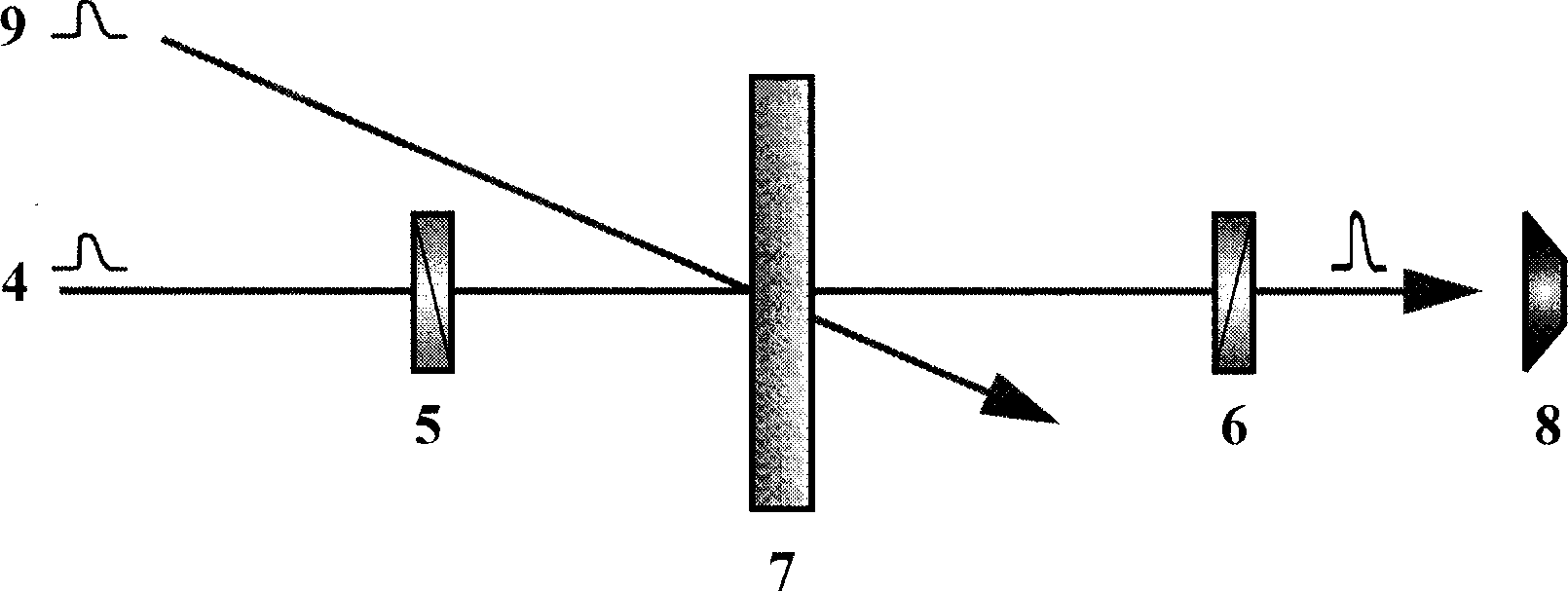

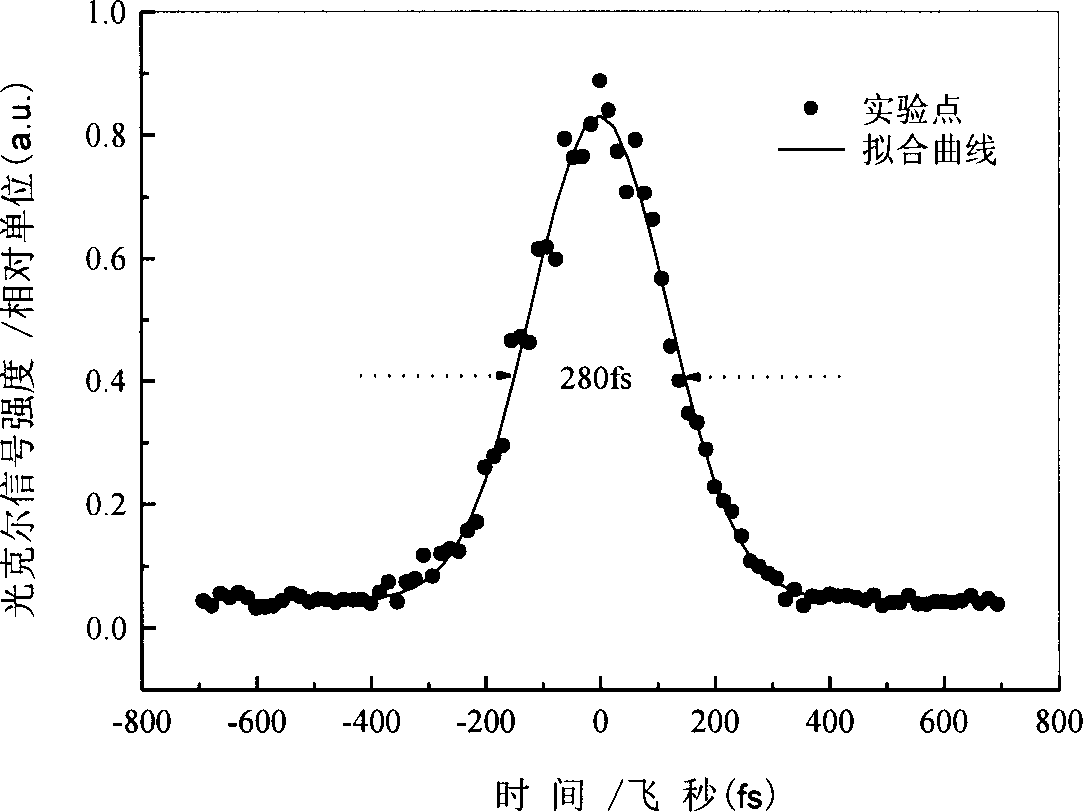

[0034] The Ag-BaO composite thin film composed of Ag nanoparticles embedded in BaO semiconductor matrix is deposited on the glass substrate. Using a multi-line argon ion laser synchronously pumped Kerr mirror mode-locked titanium sapphire laser as the laser source, the laser wavelength is 820nm, the pulse width is 120fs, the repetition frequency is 76MHz, and the output single pulse energy is about 24nJ. The laser pulse is divided into two beams according to 10:1 by the beam splitter, the stronger beam is used as the control signal, and the weaker beam is used as the input signal, and the two beams are focused on the same point on the surface of the Ag-BaO film at a certain angle. The spot diameter is about 20 μm. Firstly, the control signal light is blocked, since there are polarizers whose polarization directions are perpendicular to each other before and after the Ag-BaO film on the input signal opt...

Embodiment 3

[0036] Embodiment Three: Ultrafast Wavelength Conversion Device

[0037] A Kerr-type optical switch is constructed with Ag-BaO composite film as the working material, and a Kerr mirror mode-locked titanium sapphire laser synchronously pumped by a multi-line argon ion laser outputs a group of wavelengths of 820nm, pulse width of 120fs, repeating The laser pulse sequence with a frequency of 76MHz is used as the control signal of the optical switch, and another argon ion laser outputs a continuous laser beam with a wavelength of 514.5nm as the input signal of the optical switch. The two are incident at a certain angle and focused on the Ag- at the same point on the surface of the BaO film. Since the Ag-BaO film on the optical path of the input signal is respectively placed with polarizers whose polarization directions are perpendicular to each other, the signal at the output terminal is "0" before the control signal acts. When the control signal is effective, that is, when the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com