Plaster

A patch and pasting technology, which is applied in medical science, absorbent pads, sheet transportation, etc., can solve problems such as bad circulation, accompanied by pain, easy peeling, etc., to reduce skin irritation, improve follow-up, prevent peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Put 70 parts by weight of distilled water, 3 parts by weight of gelatin, 2 parts by weight of polyvinyl alcohol, and 2 parts by weight of kaolin into the mixer, and mix at about 50° C. to obtain a uniform dispersion. Then, add the dispersion liquid of 13 parts by weight of glycerol prepared in advance, 5 parts by weight of sodium polyacrylate, 2 parts by weight of methyl vinyl ether maleic anhydride copolymer, and 1 part by weight of aluminum hydroxide to the above-mentioned dispersion liquid, stir and mix, Then, a solution obtained by dissolving 0.5 parts by weight of ketoprofen in 1.5 parts by weight of peppermint oil was added, stirred and mixed to obtain a uniform mixture.

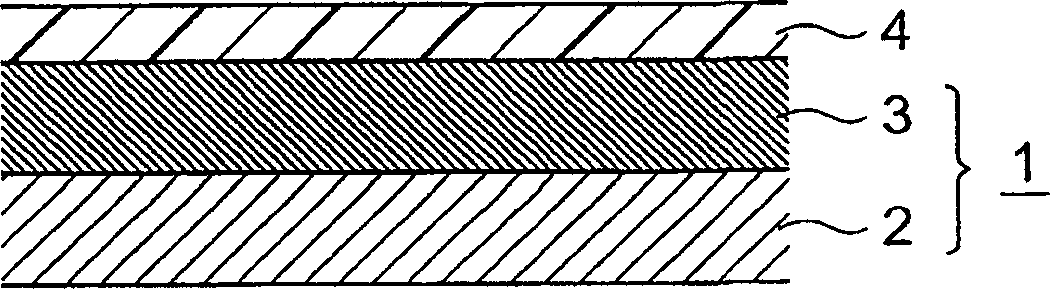

[0051] Next, the resulting mixture was stretched on a polypropylene film (stiffness: 75 mm) so that the weight after drying became 140 cm 2 It is 10g, and then it is made of polyester woven cloth (fiber thickness: 75 denier, head payment: 120g / m 2 ) of the support body covering, crimping transf...

Embodiment 2

[0053] 31.92 parts by weight of distilled water, 3 parts by weight of gelatin, 3 parts by weight of polyvinylpyrrolidone, and 3 parts by weight of zinc oxide were charged into the mixer, and mixed at about 50° C. to obtain a uniform dispersion. Then, in the above dispersion liquid, add the dispersion liquid of 50 weight parts of polyethylene glycol, 4 weight parts of sodium polyacrylate, 3 weight parts of polyacrylic acid and 0.08 weight part of polyethylene glycol diglycidyl ether prepared in advance, stir and mix , Then add the solution obtained by dissolving 0.5 parts by weight of suprofen in 1.5 parts by weight of benzyl alcohol, stir and mix to obtain a uniform mixture.

[0054] Next, the obtained mixture was stretched on a polyethylene film (stiffness: 130mm) so that the weight after drying became 140cm 2 It is 5g, and then it is woven with polypropylene (fiber thickness: 35 denier, eye payment: 110g / m 2 ) covered, crimped, transferred, cut, and made into a cataplasm of...

Embodiment 3

[0056] Disperse 4 parts by weight of synthetic aluminum silicate in 78.4 parts by weight of distilled water, add 1 part by weight of gelatin, 0.05 parts by weight of sorbitol polyglycidyl ether, 0.2 parts by weight of water-soluble placenta extract, and 0.1 parts by weight of allantoin Mix with 0.25 parts by weight of methyl p-hydroxybenzoate, add 6 parts by weight of sodium polyacrylate and 10 parts by weight of polyethylene glycol, and stir to obtain a uniform mixture.

[0057] Next, the obtained mixture was stretched on a polyester film (stiffness: 120mm) so that the weight after drying became 140cm 2 It is 10g, and then it is made of polyester woven cloth (fiber thickness: 60 denier, head payment: 110g / m 2 ) covered, crimped and transferred, cut to make a sheet-like cataplasm with a vertical length of 10 cm, a horizontal width of 14 cm, and a thickness of 2.00 mm to obtain the desired patch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com