Method for preparing selenium substitution papain

A papain and selenium generation technology, which is applied in the field of biochemistry, can solve the problems of low GPx activity of selenized subtilisin protease, and the process is not simple enough, and achieves the effects of excellent antioxidant properties, simple preparation method and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

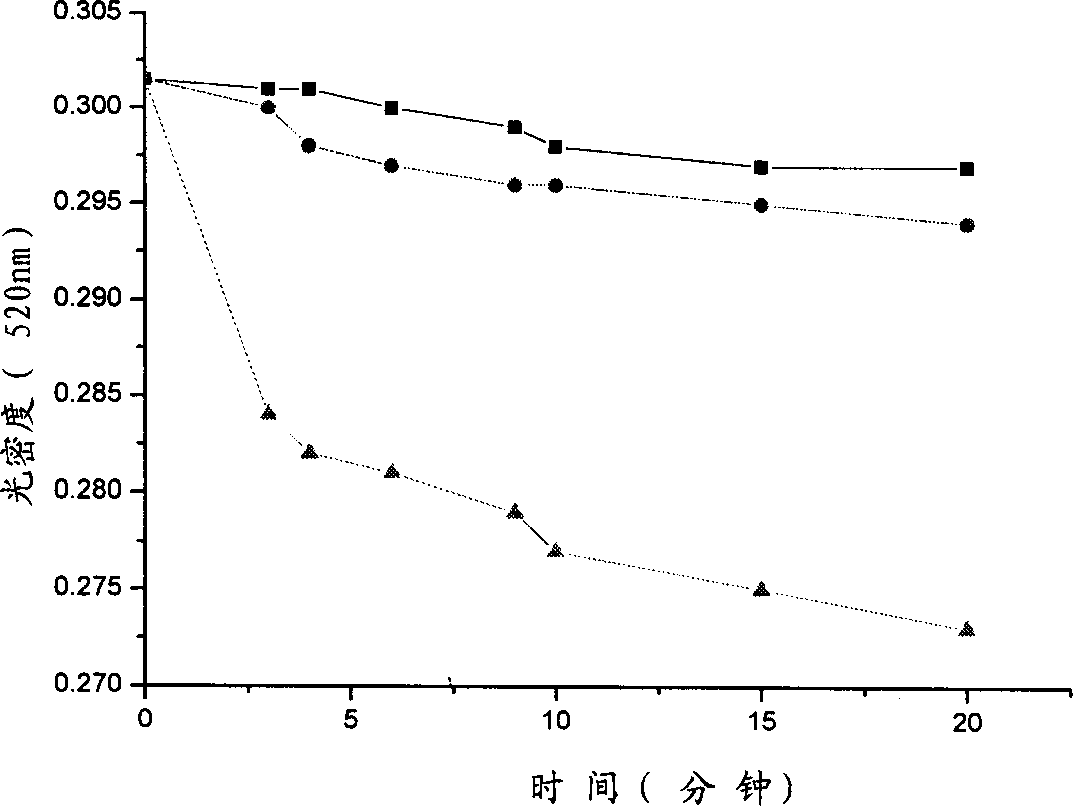

Image

Examples

Embodiment 1

[0016] Embodiment 1: the preparation of sodium selenium hydride

[0017] 81mg NaBH 4 Dissolve in a vial with 1mL of water, then slowly add 79mg of selenium powder to NaBH 4 At this moment, a large amount of gas is seen to emerge in the water, and the reaction is carried out at room temperature for 5 minutes. Then cover a plastic cover that inserts the needle until the reaction does not overflow the gas, remove the needle, seal it, and suck it out with the needle when it is used. The reaction equation is

[0018]

[0019] due to NaBH 4 with H + reaction, with a small amount of H 2 Se gas is produced. To prevent poisoning, the reaction was carried out in a fume hood.

Embodiment 2

[0020] Embodiment 2: the preparation of selenopapain

[0021] Papain (2 mg) was dissolved in 2 mL of 50 mM PBS, pH 7.0, and 200 μL of 1 M NaHSe solution prepared in Example 1 was added with a syringe, kept at 40° C. for 36 hours under nitrogen protection, then taken out and freeze-dried, and the dry powder was washed with 10 mM PBS (pH 7.0). 0) dissolving, centrifuging to remove selenium, desalting with Sephadex G-25, collecting protein peaks, and freeze-drying to obtain selenopapain. The specific activity of the obtained selenopapain can reach 44770.3U / μmol.

Embodiment 3

[0022] Embodiment 3: the preparation of selenopapain (re-selenization through activation)

[0023] Papain (2mg) was dissolved in 2mL 50mM PBS, pH7.0, 50μL PMSF (20mg / mL acetonitrile solution) was added to the above buffer solution twice every 30 minutes, incubated at room temperature for 3 hours, and then passed high-purity nitrogen for about 20 minutes to eliminate oxygen. Add 200 μL of 1M NaHSe solution prepared in Example 1 with a syringe, and keep warm at 30° C. for 36 hours under nitrogen protection. Afterwards, the aftertreatment process is the same as in Example 2. The specific activity of the obtained selenopapain can reach 54018.7U / μmol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com