Dielectric ceramic composite and electronic device

A technology of dielectric ceramics and compositions, applied in the field of electronic devices, can solve the problems of shortening the accelerated life of insulation resistance, easy reduction of DC bias reliability, and increased dielectric loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

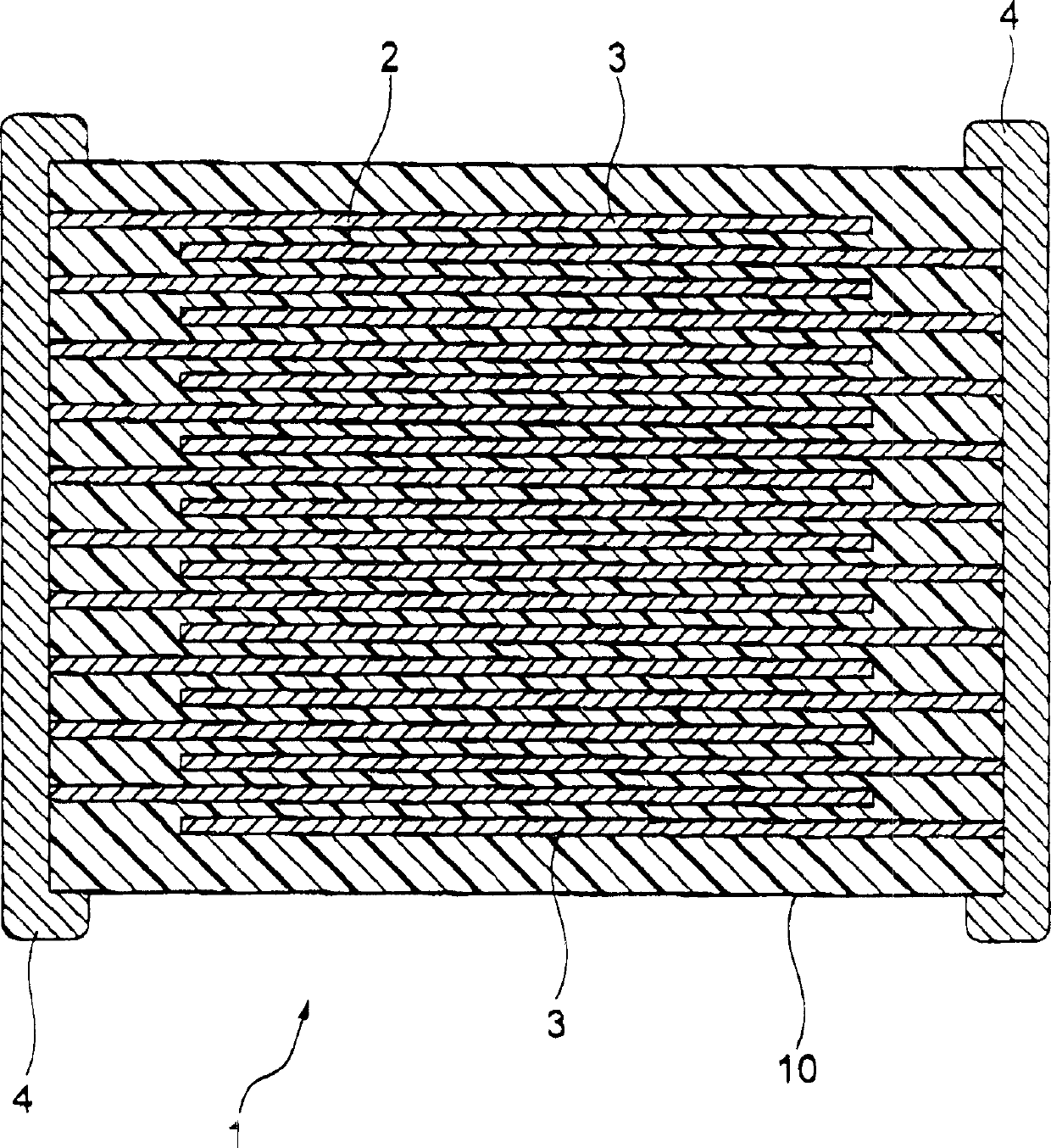

Image

Examples

Embodiment 1

[0206] Main component materials and subcomponent materials each having an average particle diameter of 0.1 to 1 micron are prepared. Carbonates are used for MgO and MnO materials and oxides are used for other materials. Note that for 100 moles of principal component material, use 3 moles of (Ba 0.6 Ca 0.4 ) SiO 3The material used as the second subcomponent. by 1.8 molar BaCO 3 , 1.2 moles of CaCO 3 and 3 moles of SiO 2 Use a ball mill to carry out wet mixing for 16 hours, dry, and burn in air at 1150° C., and use a ball mill to further carry out 100 hours of wet grinding to prepare 3 moles of (Ba 0.6 Ca 0.4 ) SiO 3 . These materials were mixed so that the composition after firing was as shown in Table 1, wet mixed for 16 hours using a ball mill and dried to become a dielectric material.

[0207] That is, in the samples of this example (samples 8, 9, 16 and 17), R1 (the fourth subcomponent) and R2 (the fifth subcomponent) were contained, and in the samples of the comp...

Embodiment 2

[0232] Capacitor samples having the compositions shown in Table 2 below were prepared in the same manner as in Example 1 (note: the thickness of each dielectric layer (middle layer thickness) was 9.5 µm). The samples of this example (samples 21-23, 23-1) contained R1 (the fourth subcomponent) and R2 (the fifth subcomponent), while the samples of comparative examples (samples 24, 19 and 20) contained only R1 ( one of the fourth subcomponent) and R2 (fifth subcomponent). Note that Sc is also contained in sample 24. In the sample of this example, R2 (fifth subcomponent) was fixed to Tb and the type of R1 (fourth subcomponent) was changed. These capacitor samples were subjected to the same measurement in the same manner as in Example 1. The results are shown in Table 2.

[0233] sample

rare earth element

Specific dielectric

constant

ε

tanδ

(%)

IR

(Ω)

CR

accumulate

(ΩF)

(%)

accele...

Embodiment 3

[0251] Capacitor samples having the compositions shown in Table 3 below were prepared in the same manner as in Example 2. In this capacitor sample, the kind and addition amount of R1 as the fourth subcomponent and the kind and addition amount of R2 as the fifth subcomponent are the same as in sample 21 of Example 2, but V 2 o 5 The point of addition amount is different from it. The same measurements as in Example 2 were performed on these capacitor samples. The results are shown in Table 3.

[0252] sample

[0253] As shown in Table 3, by putting V 2 o 5 The addition amount of the increased to the predetermined amount, confirmed the high temperature load life has an improved trend.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com