Extractant, extraction process and analysis method of high-activity ginkgo leaf extractive

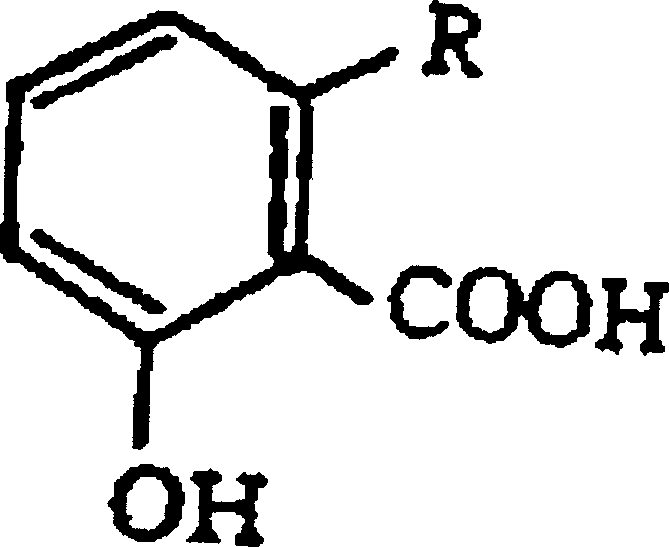

An extraction agent and technology of ginkgo biloba, which is applied in the field of natural product extraction, can solve the problems of inability to use trace samples for quantitative analysis, ginkgolic acid cannot be separated well, and cumbersome processing operations, so as to inhibit the dissolution of impurities and reduce the consumption of energy and solvents , the effect of improving the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The composition and proportion of the extractant (calculated by weight): sodium bisulfite 10kg; tap water 8000kg; pH5.0.

[0075] Clean 300kg of dried ginkgo leaves, filter the water, put them into the extraction tank, add 5000kg of extractant at 94°C, cover and seal, raise the temperature in the extraction tank to 97°C, and keep 1 atmospheric pressure, stirring every half an hour For 1 minute, the temperature in the tank was controlled to drop by 2.5°C per hour. After leaching for 16 hours, 4400kg of the feed liquid was filtered out. Then add 3000kg of extractant solution to the extraction tank for the second leaching, filter out 3100kg of feed liquid after 10 hours, combine the two feed liquids with a centrifugal filter to coarsely filter out impurities below 20 mesh, and sand filter to fine filter out Impurities below 200 mesh were removed, and the feed liquid was cooled to 30°C.

[0076] The feed liquid flows through the NKA-9 resin adsorption column at a flow rate...

Embodiment 2

[0079] The composition and proportion of the extractant (calculated by weight): sodium sulfite 5kg; water 6000kg; pH 5.5.

[0080] Take 300kg of dried ginkgo leaves (Hubei Anlu) and clean them, filter the water, put them into the extraction tank, add 4000kg of extractant at 93°C, cover and seal, stir for 3 minutes every half hour, and after leaching for 10 hours, the temperature in the tank drops to 60°C, filter out the feed liquid, add 2000kg of extractant for the second extraction, filter after 6 hours, combine the two extracts to a total of 5600kg, and use the centrifugal filter for coarse filtration of the feed liquid, sand filter for fine filtration, and cool to 35 ℃; Still using the resin column in Example 1 to refine, collect ethanol eluent 1300kg, after concentrating to 40kg, adopt spray drying to obtain 9.02kg light yellow ginkgo leaf extract.

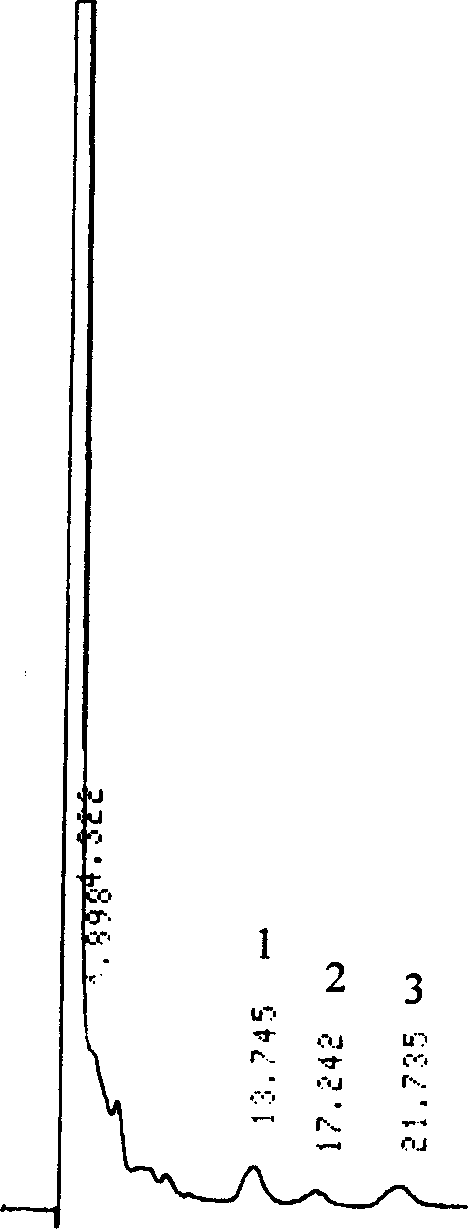

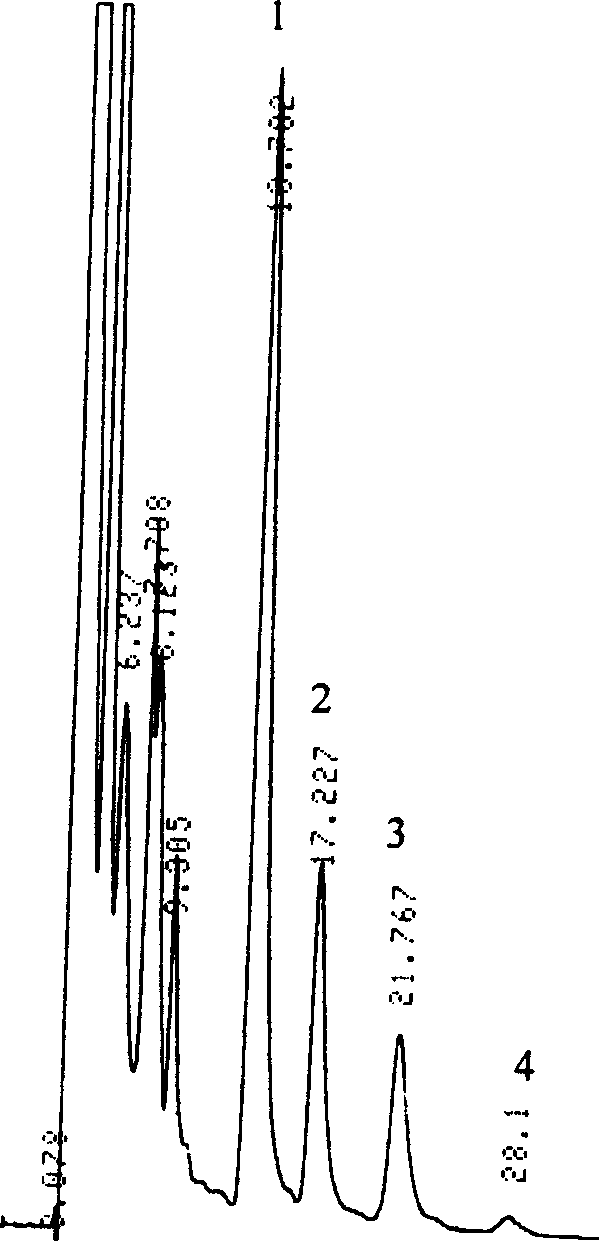

[0081] Test results: total flavonoid glycosides 27.6%, total terpene lactones 8.1%, proanthocyanidins 9.6%, ginkgolic acid 4...

Embodiment 3

[0083] The composition and proportion of the extractant (calculated by volume): sodium bisulfite 9kg; tap water 4500kg; pH 4.8.

[0084] Take 600kg of freshly picked ginkgo leaves (water content 72%) and 3000kg of extractant and put them into the extraction tank together, control the temperature at 70°C, stir intermittently for 10 minutes per hour, after leaching for 20 hours, filter out the material liquid, and extract with 1500kg The second extraction was carried out for another 20 hours, the two extracts were combined and filtered, and 4400kg of the filtrate flowed through the ADS-17 resin adsorption column for three hours, followed by washing the column with 6000kg of tap water and 1000kg of deionized water, followed by washing with 70% ethanol After the ethanol eluate was concentrated to 20kg, it was freeze-dried to obtain 4.81kg of the product.

[0085] Test results: total flavonoid glycosides 36.0%, total terpene lactones 12.8%, proanthocyanidins 12.5%, ginkgolic acid 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com