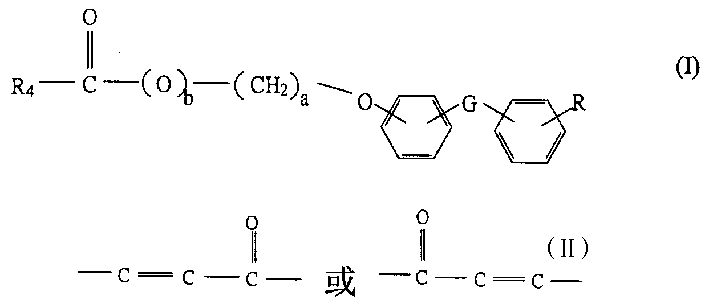

Acrylate compound, preparing process thereof and its use

An acrylate and compound technology, applied in the field of acrylate polymers, can solve the problems of lowering the quality of liquid crystal displays, failing to meet demands, and generating static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0049] Example Example 1 Preparation of Acryloyl Chloride

[0050] Acrylic acid (68 mL, 1.0 mol) and phosphorus trichloride (29 mL, 0.33 mol) were added to a flask equipped with a reflux condenser. The mixture was heated slowly to a slight boil, then turned off the heat. After standing for 2 hours to separate the layers of the reaction mixture, separate the supernatant liquid, add cuprous chloride (1.0 g) as a polymerization inhibitor, and then distill under reduced pressure to collect fractions at 30-40°C / 140mmHg. Example 2 Preparation of methacryloyl chloride

example 2

[0051] A flask equipped with a reflux condenser was charged with methacrylic acid (83 mL, 1.0 mol) and phosphorus trichloride (29 mL, 0.33 mol). The mixture was heated slowly to a slight boil. After standing still for 2 hours, the reaction mixture was separated into layers, and the supernatant liquid was separated. Cuprous chloride (1.0 g) was added as a polymerization inhibitor, and the methacryloyl chloride product was obtained by distillation under reduced pressure. Example 3 (1) Synthesis of 4-hydroxyl chalcone (4-hydroxyl chalcone)

example 3

[0051] A flask equipped with a reflux condenser was charged with methacrylic acid (83 mL, 1.0 mol) and phosphorus trichloride (29 mL, 0.33 mol). The mixture was heated slowly to a slight boil. After standing still for 2 hours, the reaction mixture was separated into layers, and the supernatant liquid was separated. Cuprous chloride (1.0 g) was added as a polymerization inhibitor, and the methacryloyl chloride product was obtained by distillation under reduced pressure. Example 3 (1) Synthesis of 4-hydroxyl chalcone (4-hydroxyl chalcone)

[0052] Weigh 2.44 grams (0.02 moles) of 4-hydroxybenzaldehyde and 2.40 grams (0.02 moles) of acetophenone, dissolve it with 5 milliliters of absolute ethanol, then slowly drop into 5.5 milliliters of 50% KOH solution, then add an appropriate amount of Dilute hydrochloric acid produces precipitation, which is 4-hydroxychalcone. (2) Preparation of (4-hydroxychalcone) acrylate (MACH)

[0053] Weigh 1 g (0.004464 moles) of 4-hydroxychalcone a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com