Large-mixed flyash waterproof and heat-insulating material and construction method thereof

A technology of thermal insulation material and fly ash, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of many processes, poor material complementarity, and high engineering cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

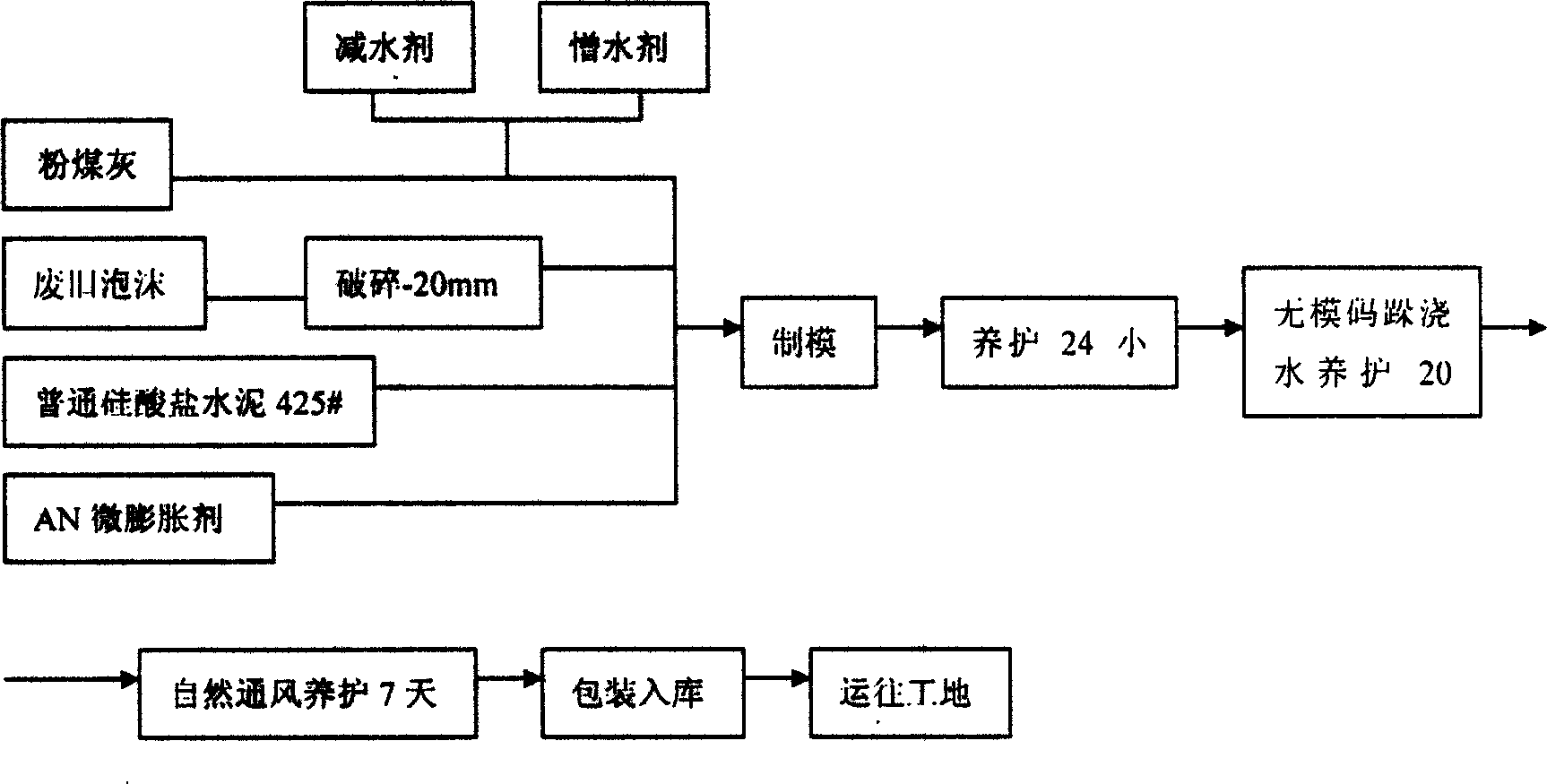

Image

Examples

Embodiment 1

[0030] Example 1: 30m2 small-scale project overall pouring. No cracking or leakage after multiple continuous rainy days for more than 1 week. Construction thickness: heat insulation and waterproof main layer 8cm, mortar protection layer 2cm. Measured at 2 o'clock in the afternoon on a sunny day, the outdoor air temperature is 36°C, the top surface temperature is 72°C, the indoor temperature (air conditioner) is 26°C, and the bottom surface temperature of the roof panel is 28°C. Before the transformation, T-shaped cement boards were used for heat insulation, and two felts and three oils were used for waterproofing. After the renovation, the same air conditioner is used to maintain the indoor temperature at 26°C, which saves 1.2kW·h of electricity per hour compared with that before the renovation.

Embodiment 2

[0031]Example 2: Brick paving, old house surface repair project, with complex roof structure, roof attached exhaust fan, original chimney, etc. After using 1:4 cement mortar for slope finding, three layers of ARPE flexible water prevention materials were laid. The joints of ARPE materials and special parts of the roof were waterproofed with neoprene latex water-soluble bitumen waterproof coating and high-performance adhesives. On the waterproof layer, large-volume fly ash waterproof and heat-insulating material blocks are used for roofing construction, and the expansion mortar prepared by self-developed AN micro-expansion agent is used between the blocks to fill the joints. When the temperature reaches 65°C, there is no significant difference between the indoor air temperature and the outdoor shade (30°C-32°C), so it can be seen that the waterproof and heat-insulating effect of this material is excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com