New technology for preparating N-phosphono methyl glycine

A technology of phosphonomethylglycine and glycine, which is applied in the field of preparation of herbicide N-phosphonomethylglycine, can solve the problems of low product quality, high refining cost, and low working concentration, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

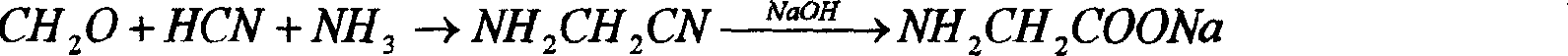

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described below with a specific process, and the contents used are all percentages by weight.

[0022] Embodiment 1-1 Get 1000g content and be 34% sodium glycinate aqueous solution, add 215g content and be the sulfuric acid of 80%, fully stir, and record pH value is 6, is that heating and concentrating under 0.08Mpa in vacuum tightness, steams 598g water. Cool to 25°C, filter, and dry to obtain 458g of mixed crystals of glycine and sodium sulfate, wherein the content of glycine is 52%, and the content of sodium sulfate is 48%.

[0023] Embodiment 1-2 Get 1000g content of 34% sodium glycinate aqueous solution, add 415g content of 31% hydrochloric acid, fully stir, record the pH value as 5, heat and concentrate under vacuum degree of 0.08Mpa, steam out 804.5g water . Then cooled to 25° C., filtered, and dried to obtain 382.7 g of mixed crystals of glycine and sodium chloride, wherein the content of glycine was 60.2%, and the content of sodium chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com