Manufacturing method of polycrystal film and manufacturing method of oxide superconductor

A manufacturing method and oxide technology, which is applied in superconducting/high-conducting conductors, manufacturing/processing of superconducting devices, crystal growth, etc., can solve the problems of large number of necessary layers and increased manufacturing steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

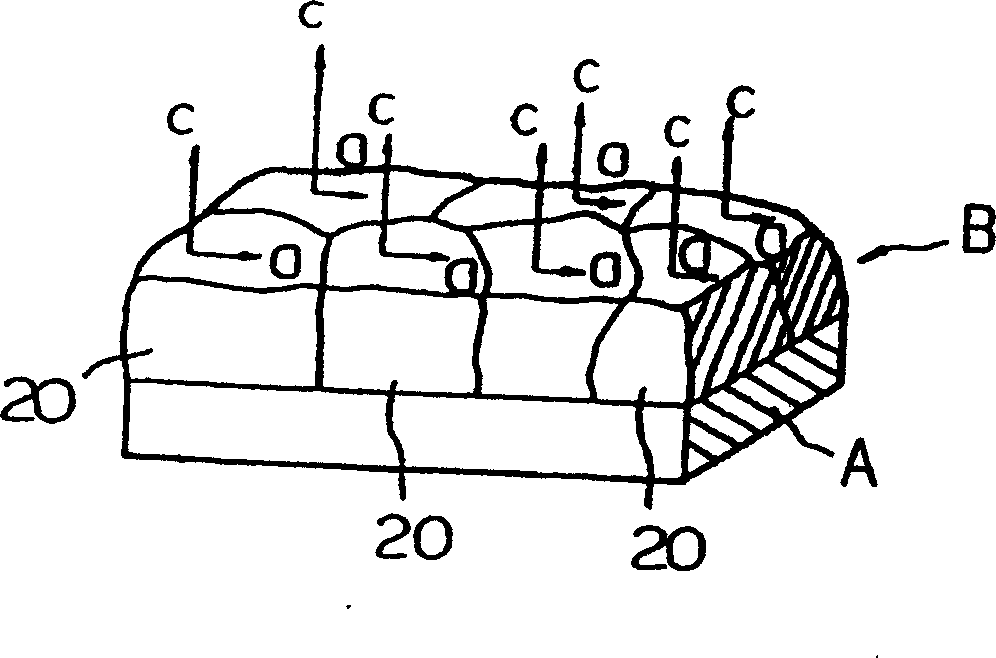

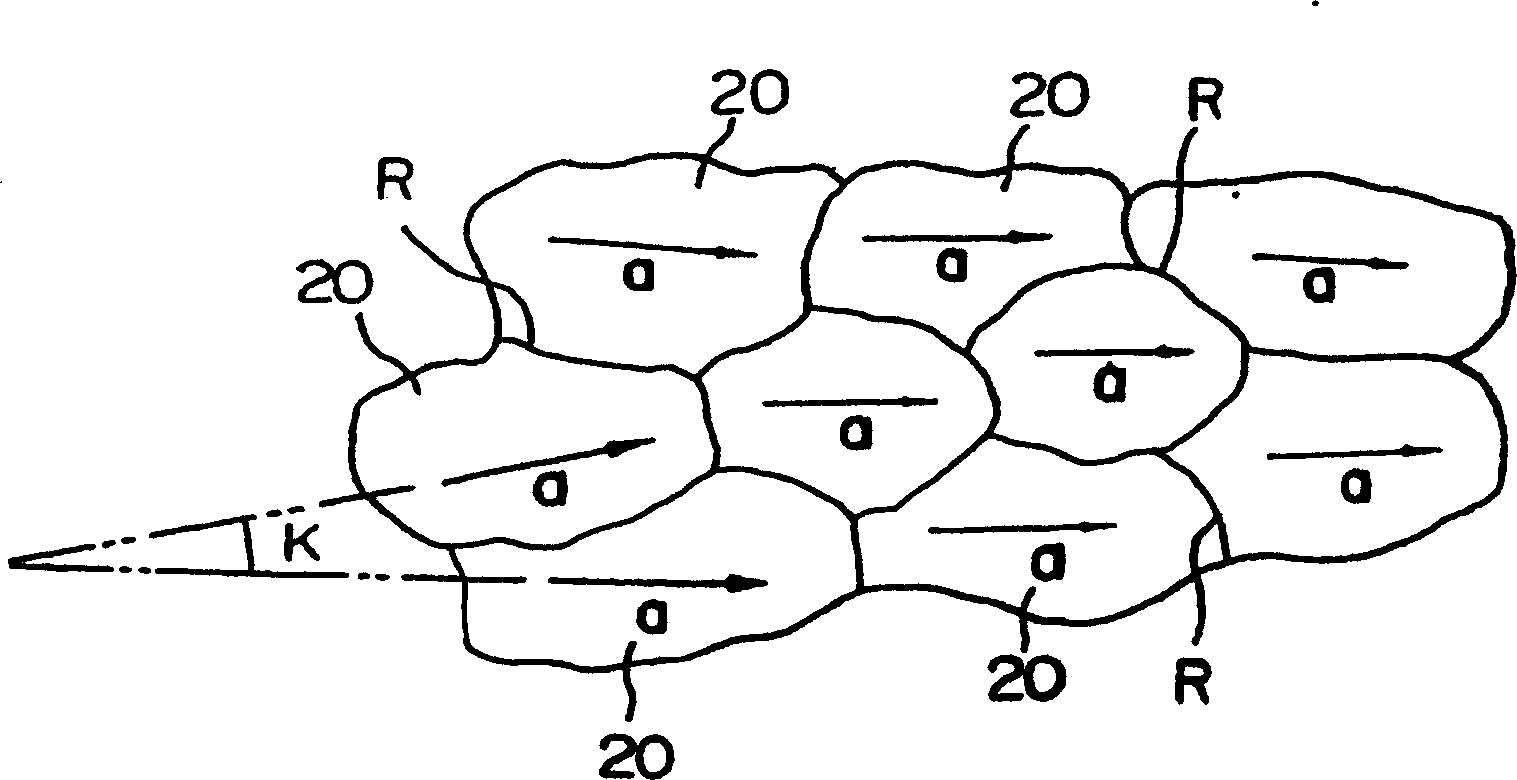

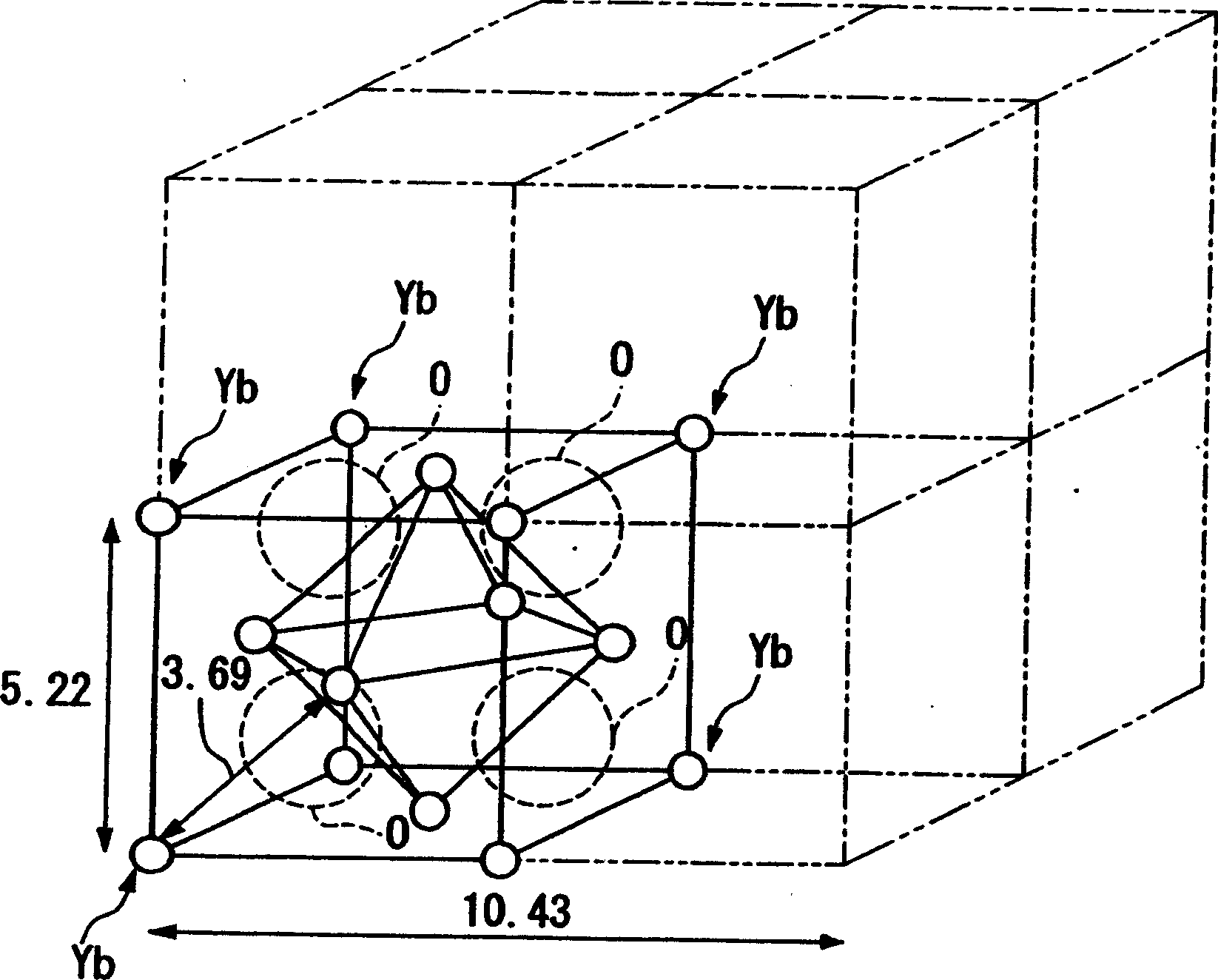

[0091] use Figure 4 The device for producing polycrystalline thin films is shown, in which the pressure in the film forming chamber is reduced to 3.0×10 by exhausting using a rotary pump and a cryopump. -4 Torr (4×10 -2 Pa), a mirror-polished nickel-based alloy C276 tape with a width of 10 mm, a thickness of 0.5 mm, and a length of 100 cm was used as a tape-shaped substrate. Use containing Yb 2 o 3 target, the sputtering voltage was set at 1000V, the sputtering current was set at 100mA, and the Kr ejected from the ion source + The incident angle of the ion beam to the normal of the film forming surface was set at 55 degrees, the transmission distance of the ion beam was set at 40 cm, the sputtering voltage of the ion beam was set at 150 eV, and the current density of the ion beam was set at 100 μA / cm 2 , moreover, when the temperature of the substrate strip was set to 300 °C and the oxygen inflow to 1×10 -4 Torr (1.3×10 -2 In the environment of Pa), the constituent part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com