Method for preparing luminescent powder of light emitting diode in white light with high brightness and adjustable wavelength

A technology of light-emitting diodes and phosphors, which is applied in the direction of luminescent materials, chemical instruments and methods, and sustainable buildings. It can solve the problems that the luminous brightness cannot meet the needs, and the luminous intensity of phosphors needs to be improved, so as to improve the color temperature and color coordinates. The effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] weigh Y 2 o 3 : 4.0g, Al 2 o 3 : 3.1g, activator CeO 2 : 0.3g, flux NaF: 0.5g and H 3 BO 3 : 0.1g, mixed and ground for 20-40min, put into a crucible, baked at 1200°C-1550°C for 5 hours in a reducing atmosphere provided by a carbon rod, stopped heating and then cooled to obtain the phosphor powder of the present invention.

Embodiment 2

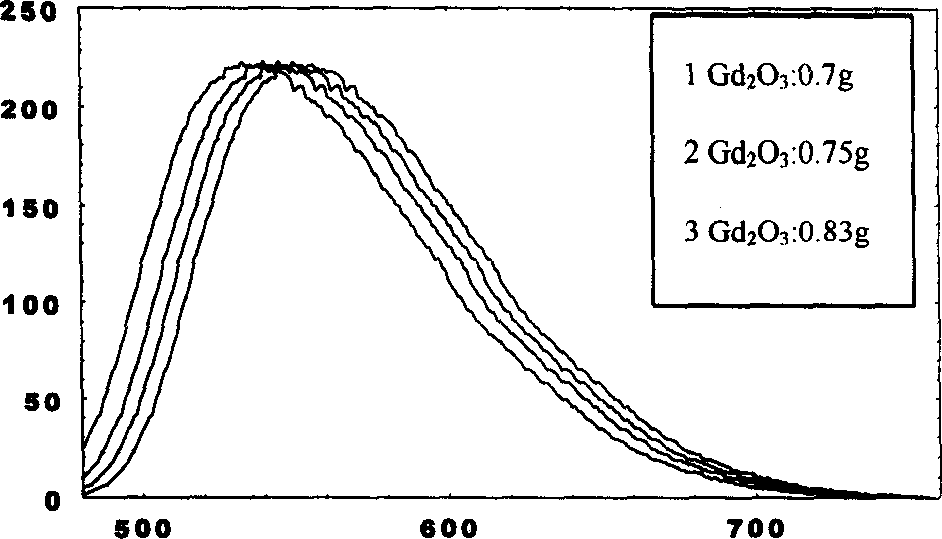

[0013] The mixture described in the present invention also can be mixed with rare earth element R, promptly adopts main chemical composition to be (Y 1-x-y Ce x R y ) 3 Al 5 o 12 , wherein R is erbium (Er), praseodymium (Pu), gadolinium (Gd), terbium (Tb) or gallium (Ga), x=0.01-0.05, y=0.15-0.5. Weighing aluminum oxide, yttrium oxide, cerium oxide and rare earth oxide according to the chemical formula ratio, and adding 1%-5% mole flux at the same time, and mixing them into raw materials for preparing white light phosphor. During the specific operation, weigh Y 2 o 3 : 4.0g, Al 2 o 3 : 3.1g, CeO 2 : 0.3g, NaF: 0.5g, H 3 BO 3 : 0.1g, Gd 2 o 3 : 0.7g, mix and grind for 20-40min, put it into a crucible, and bake it at 1200°C-1550°C for 5 hours in the reducing atmosphere provided by the carbon rod, stop heating and cool down rapidly to get the phosphor. Place in 5% nitric acid aqueous solution, stir well at room temperature for 20-30 minutes, separate the phosphor po...

Embodiment 3

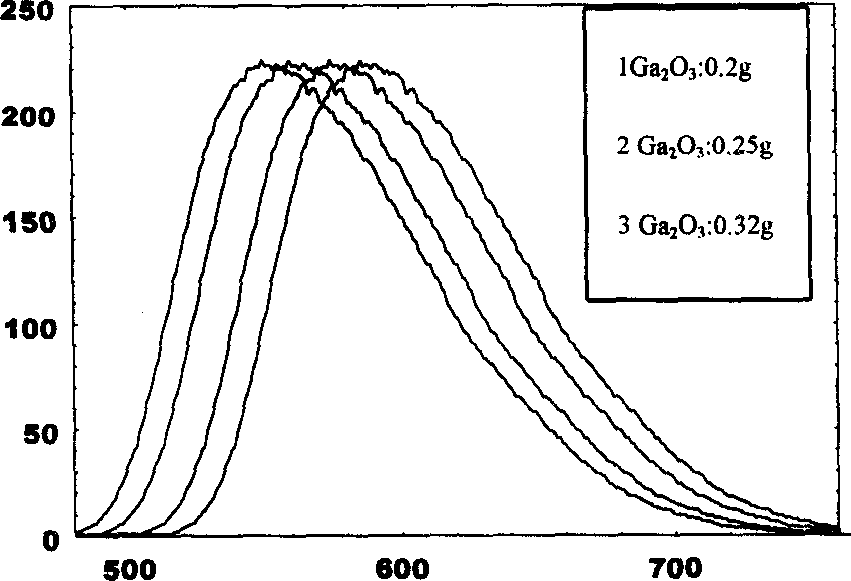

[0015] weigh Y 2 o 3 : 4.0g, Al 2 o 3 : 3.1g, CeO 2 : 0.3g, NaF: 0.5g, H 3 BO 3 : 0.1g, Ga 2 o 3 : 0.2g, mix and grind for 20-40min, put it into a crucible, bake at 1200°C-1550°C for 5 hours in a reducing atmosphere provided by a carbon rod, stop heating and cool rapidly, and place the obtained powder in 5% nitric acid In the aqueous solution, fully stir at room temperature for 20-30 minutes to separate the fluorescent powder, and dry it at 100°C-120°C for 1 hour to obtain a high-brightness fluorescent powder with a blue-shifted wavelength.

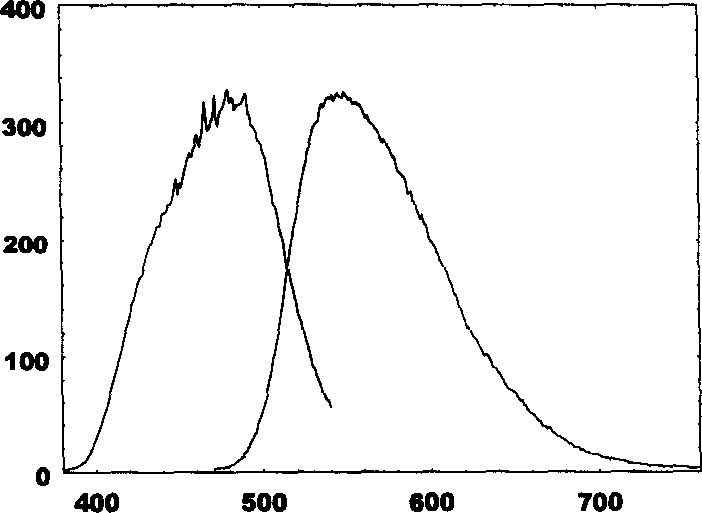

[0016] From attached figure 1 , attached figure 2 And attached image 3 It can be seen that doping with rare earth elements can red-shift or blue-shift the emission wavelength. attached figure 2 It shows that the emission wavelength has different red shifts with the amount of doped gadolinium (Gd). attached image 3 It is shown that the emission wavelength has different blue shifts with the amount of gallium (Ga) doped.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous intensity | aaaaa | aaaaa |

| luminous intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com