Process for producing fine calcium carbonate by wet carbon solidification method using industrial flue

A technology of fine calcium carbonate and industrial flue gas, applied in the direction of calcium carbonate/strontium/barium, separation methods, chemical instruments and methods, etc., can solve problems such as failure to fully utilize effective resources, limit application development, and complex processing methods. Achieve the effects of high product added value, low input cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

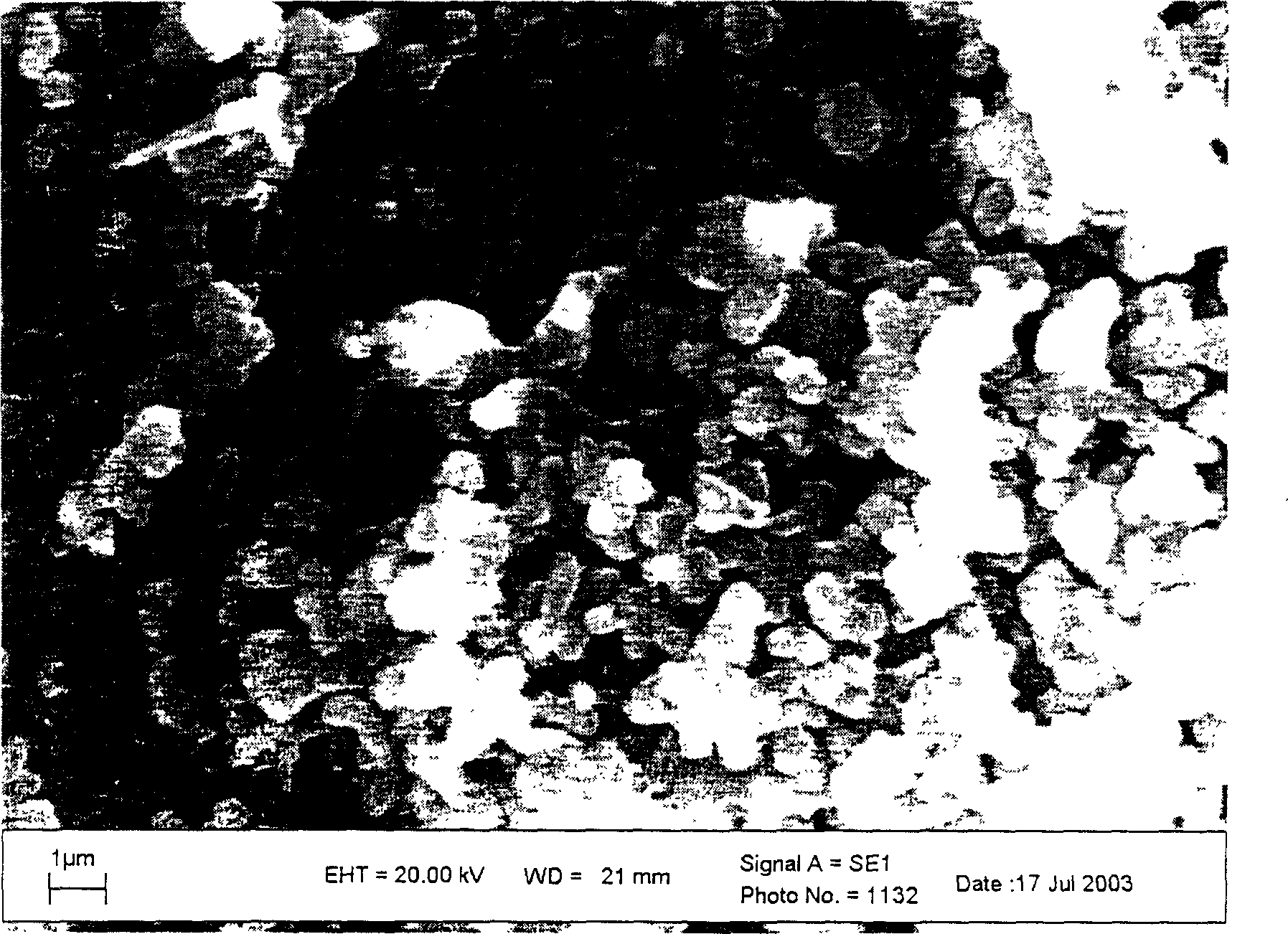

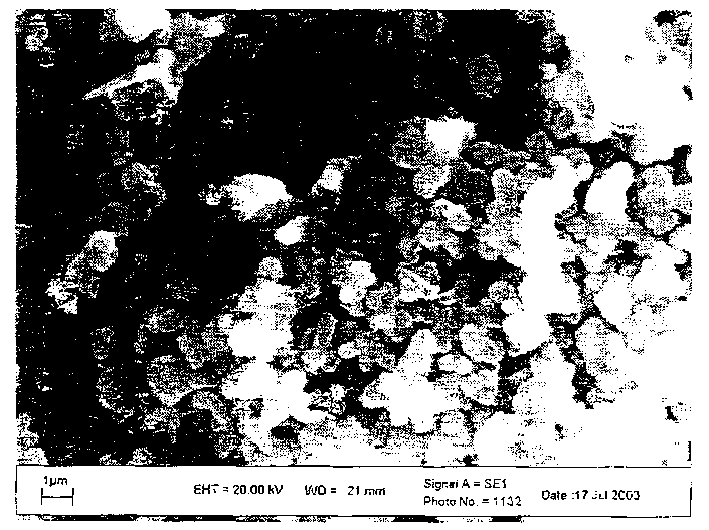

Image

Examples

example 1

[0016] Example 1: Add 2.5 liters of NaOH solution with a molar concentration of 0.2 mol / liter to each of the two-stage decarburization containers of the test device, ignite solid alcohol fuel in the combustion chamber, and control the intake volume of the combustion chamber to make the combustion stable. Start the pumping device again, let the gas pass into the NaOH solution, stop the reaction after 60 minutes, and absorb CO in the first-stage decarburization device 2 0.183 moles, absorbing CO in the secondary decarburization unit 2 0.850 moles.

[0017] Take 1000ml of primary decarburization treatment liquid, add appropriate amount of dispersant and surface modifier to it for use.

[0018] Weigh 4.1g CaO solid and 20g water, put CaO solid into water, the two react violently. Leave the reaction vessel clean for 5 minutes, then add about 200ml of water to form a well-dispersed Ca(OH) 2 suspension.

[0019] The treated solution was stirred, the suspension was gradually added...

example 2

[0020] Example 2: Add 2.5 liters of NaOH solution with a molar concentration of 2 mol / liter in the decarburization container of the test device, ignite the solid alcohol fuel in the combustion chamber, control the intake air volume of the combustion chamber, and make the combustion stable. Start the pumping device again, let the gas pass into the NaOH solution, stop the reaction after 60 minutes, and absorb CO in the first-stage decarburization device 2 1.168 moles, absorbing CO in the secondary decarburization unit 2 0.176 mol.

[0021] Take 1000ml of primary decarburization treatment liquid, add appropriate amount of dispersant and surface modifier to it for use.

[0022] Weigh 26g of CaO solid and 130g of water, put the CaO solid into water, and the two react violently. Leave the reaction vessel clean for 5 minutes, then add about 500ml of water to form a well-dispersed Ca(OH) 2 suspension.

[0023] Stir the treatment solution, gradually add the suspension to it, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com