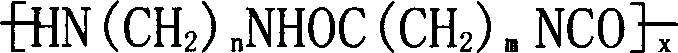

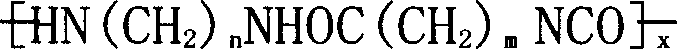

Long carbon chain nylon and its synthesis method

A synthesis method and long carbon chain technology, applied in the field of polyamide engineering plastics and its synthesis, can solve problems such as ineffectiveness, deterioration of heat resistance and rigidity of polyamide materials, and change of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 40kg of tridecanedioic acid produced by the fermentation method into a reactor with agitated distillation, heat at 130°C to melt the tridecanedioic acid, feed ammonia gas, and control the flow rate of ammonia gas at 60m 3 After 10 hours of dehydration reaction, the temperature was raised to 350° C., kept for 4 hours, distilled under reduced pressure, and tridecanedinitrile was distilled off.

[0047] Add 30kg of tridecanedinitrile, 60kg of ethanol (95%), 3.0kg of skeleton nickel, and 20kg of liquefied ammonia into the autoclave, extract the gas in the autoclave under reduced pressure, feed hydrogen into the autoclave and keep the pressure at 2Mpa, and heat up The temperature of the reaction kettle was controlled at 120° C., and the temperature was lowered to 60° C. after 1 hour. The inside of the reaction kettle was lowered to normal pressure, the catalyst was filtered out, ethanol and ammonia were distilled off to obtain tridecanediamine.

[0048] Add the refined t...

Embodiment 2

[0051] Add 40kg of tetradecanedioic acid produced by fermentation into a reactor with agitated distillation, heat at 140°C to melt the tetradecanedioic acid, feed ammonia gas, and control the flow rate of ammonia gas at 60m 3 After 12 hours of dehydration reaction, the temperature was raised to 350° C., kept for 4 hours, and distilled under reduced pressure to distill tetradecanedinitrile.

[0052] Add 30kg of tetradecanedinitrile, 60kg of ethanol (95%), 3.6kg of skeleton nickel, and 24kg of liquefied ammonia into the autoclave, extract the gas in the autoclave under reduced pressure, and feed hydrogen into the autoclave to keep the pressure at 2.5MPa. Raise the temperature so that the temperature of the reactor is controlled at 120° C. After 60 minutes, the temperature is lowered to 60° C., the inside of the reactor is reduced to normal pressure, the catalyst is filtered out, ethanol and ammonia are distilled off to obtain tetradecanediamine.

[0053] Add the refined tetradec...

Embodiment 3

[0056] Add 40kg of pentadecanedioic acid produced by the fermentation method into a reactor with agitated distillation, heat at 150°C to melt pentadecanedioic acid, feed ammonia gas, and control the flow rate of ammonia gas at 60m 3 After 12 hours of dehydration reaction, the temperature was raised to 350° C., kept for 4 hours, and distilled under reduced pressure to distill pentadecanedinitrile.

[0057] Add 30kg of pentadecanedinitrile, 60kg of ethanol, 4.5kg of skeleton nickel, and 18kg of liquid ammonia into the high-pressure reactor, extract the gas in the reactor under reduced pressure, and feed hydrogen into the reactor to keep the pressure at 1.5MPa. The temperature is controlled at 120°C, and after 60 minutes, the temperature is lowered to 60°C, the pressure in the reactor is lowered to normal pressure, the catalyst is filtered out, and ethanol and ammonia are distilled off to obtain pentadecanediamine.

[0058] Add the refined pentadecanedioic acid: ethanol in the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com