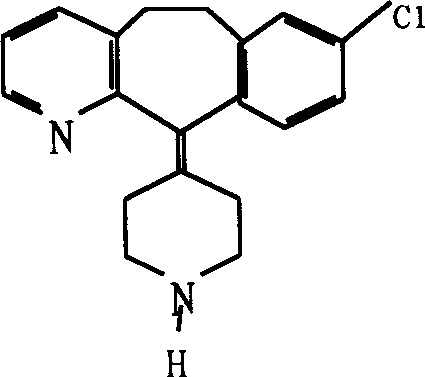

Desloratadine dry-mixed suspensoid and preparing method thereof

A technology of desloratadine and dry suspension, applied in the field of new dosage forms and preparation thereof, can solve the problems of easy deterioration, dispersible tablet volume can not be too large, thermodynamic instability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: respectively use hydroxypropyl methylcellulose (HPMC), ethylcellulose (EC), aminoalkyl methacrylate copolymer E type (EUDRAGIT E100) to screen the coating solution to finally determine the coating material. Coating weight gain 10%. Raw material coating screening

[0015] Test 1: HPMC 25g

[0016] Propylene glycol 10ml

[0017] Castor Oil 10ml

[0018] Polysorbate 80 10ml

[0019] Ethanol 500ml

[0020] Water 500ml Process: Weigh 25g HPMC, dissolve it with 500ml hot water, cool to room temperature to form a viscous solution, add 500ml ethanol, stir well, add castor oil, polysorbate 80, propylene glycol, stir well;

[0021] Test 2: EC 25g

[0022] Isopropanol 150ml

[0023] Ethanol 850ml Process: Weigh 25g EC, dissolve in 150ml isopropanol, 850ml

[0024] In ethanol, dissolve.

[0025] Test 3: EUDRAGITE100 25g

[0026] Ethanol 1000ml Process: Weigh 25g EUDRAGIT E100, soluble

[0027] In 1000ml ethanol, it is a trans...

Embodiment 2

[0032] prescription

[0033] Uncoated Desloratadine 2.5g

[0034] Sucrose 212g

[0035] Mannitol 270g

[0036] Sodium Carboxymethyl Cellulose 10g

[0037] Sweet orange essence 0.5g

[0038] Xanthan Gum 5g

[0039] Sunset yellow 0.001g, 1000 bags in total Process: Pass the above ingredients through a 100-mesh sieve and mix well. Spray for coloring, dry and dispense.

Embodiment 3

[0041] prescription

[0042] Coated desloratadine raw material 2.5g

[0043] (calculated as desloratadine)

[0044] Sucrose 212g

[0045] Mannitol 270g

[0046] Sodium Carboxymethyl Cellulose 10g

[0047] Sweet orange essence 0.5g

[0048] Xanthan Gum 5g

[0049] Sedimentation volume ratio

[0050] The above experiments show that the taste of desloratadine produced by the present invention is obviously improved, and the raw materials are also extremely stable after being coated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com