Engineering fungi for utilisation of L-arabinose

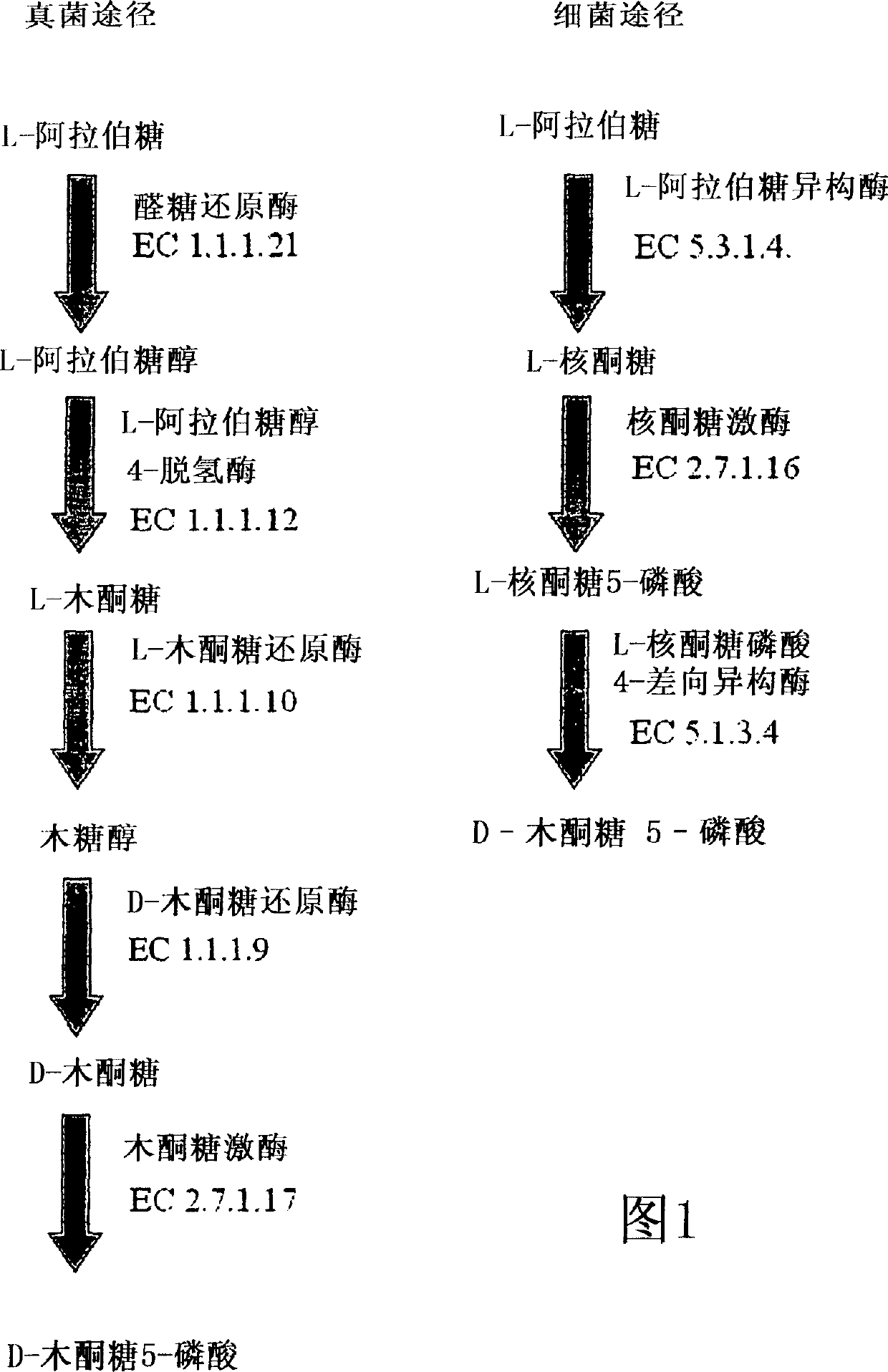

A technology of arabinose and arabitol, applied in the field of genetically modified fungi, can solve the problem of ineffective utilization of L-arabinose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Purification and amino acid sequence determination of L-arabitol 4-dehydrogenase:

[0051] Tricoderma reesei (Rut C-30) contains 40g / l L-arabinose, 2g / l prion peptone, 15g / l KH 2 PO 4 , 5g / l (NH4) 2 SO 4 , 0.6g / l Mg 2 SO 4 ×7H 2 O, 0.8g / l CaCl 2 ×2H 2 O and trace elements in medium (Mandels and Weber, 1969), grown in fermentors (Chepmap CF2000) at 28°C, pH 4.0 and 30% dissolved oxygen. Fermentation was stopped when L-arabinose was about 10 g / l. Cells were harvested with a plastic mesh and washed with 10 mM sodium phosphate (pH 7). 500 g of biomass was frozen in liquid nitrogen in 100 g portions. After thawing and sonicating with a pointed sonicator, DTT was added to a final concentration of 5 mM, and the suspension was centrifuged (Sorvall SS34, 40 minutes, 20000 rpm). The supernatant was dialyzed overnight with 10 volumes of buffer A (10 mM sodium phosphate pH 7, 5 mM DTT). The retentate was then centrifuged (Sorvall SS34, 40 min, 20000 rpm). All steps wer...

Embodiment 2

[0064] Cloning of L-arabitol 4-dehydrogenase:

[0065] Cloning gene fragments using internal amino acid sequences:

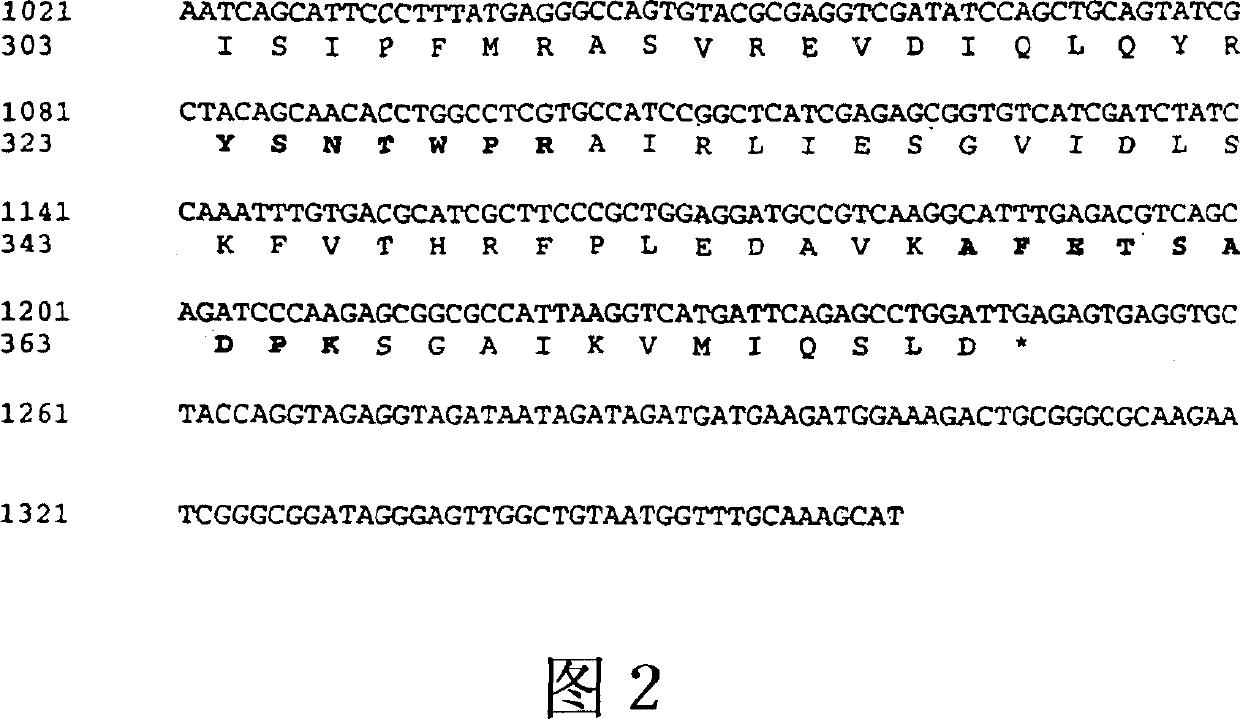

[0066] Design PCR degenerate primers using internal peptide sequences. The template in the first step is the genomic DNA of Tricoderma reesei. A sense DNA sequence corresponding to the amino acid fragment A T G A AI S V K P N I G V F T N P K (primer 5384: ARCCIAAYATHGGIGTITTYACIAAYCC) and an antisense DNA sequence corresponding to the amino acid fragment A F E T S A DP K (primer 5285: GGRTCIGCIGAIGTYTCRAAIGC) were used. The PCR conditions are: denaturation at 96°C for 30 seconds, annealing for 30 seconds, extension at 72°C for 2 minutes (first two times at 37°C, then 27 times at 42°C), and last extension at 72°C for 5 minutes. This process yields a PCR product of approximately 1 kb. The resulting approximately 1 kb fragment was then cloned into TOPO vector (Invitrogen).

[0067] This construct was then used for sequencing.

[0068] The PCR product sequence ...

Embodiment 3

[0082] Expression of L-arabitol 4-dehydrogenase in Saccharomyces cerevisiae:

[0083] The 1.1 kb EcoRI and BamHI fragments in the TOPO vector were ligated to the corresponding sites of the pYX242 vector (R & D Systems). pYX242 is a multi-copy yeast expression vector with yeast TPI promoter and LEU2 for selection. This plasmid was then transformed into Saccharomyces cerevisiae strain CEN.PK2(VW1b). Recombinant yeast cells are grown in selective media. The intracellular proteins of the yeast cells were then extracted using glass bead vortexing. The extracts were then analyzed for L-arabitol dehydrogenase activity. We found L-arabitol 4-dehydrogenase activity to be 0.2-0.3 nkat per mg of extracted protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com