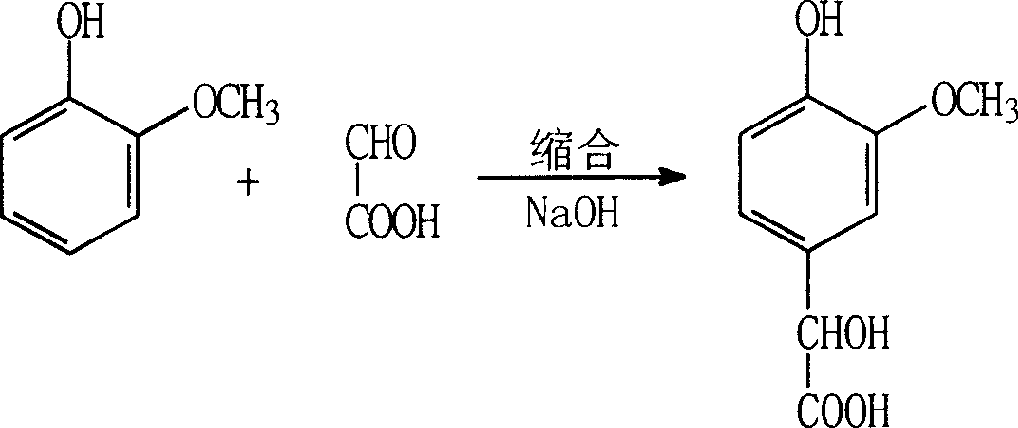

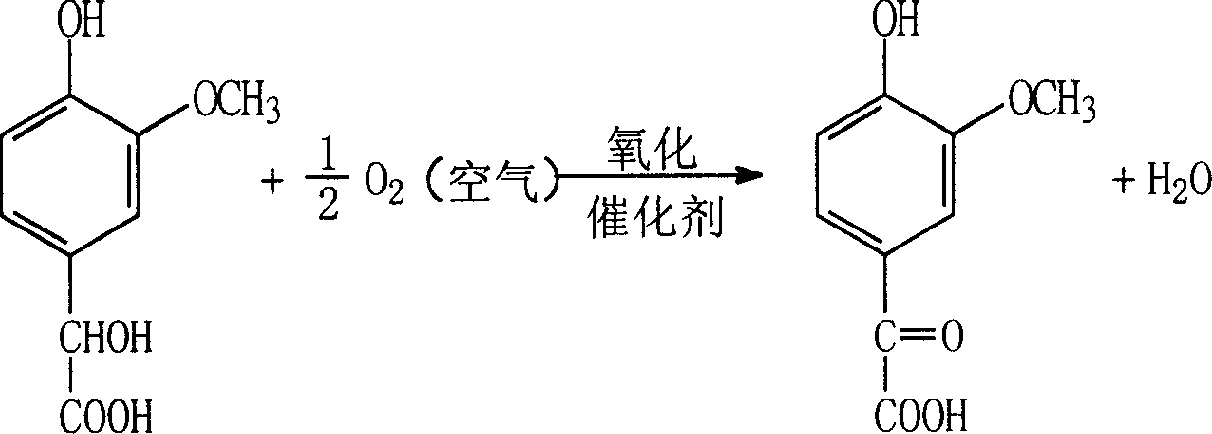

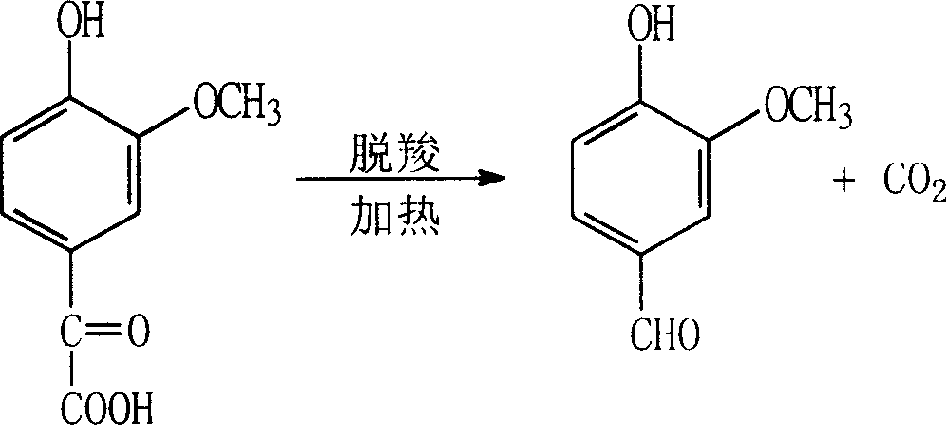

Oxydation catalyst used in synthesizing 4-hydroxy 3-methoxy benzaldehyde and 4-hydroxyl-3-ethoxy benzaldehyde by glyoxalic acid method

A technology of methoxybenzaldehyde and ethoxybenzaldehyde, applied in physical/chemical process catalysts, condensation preparation of carbonyl compounds, organic chemistry, etc., can solve problems such as difficult filtration, large amount of copper sulfate, and easy blockage of the filter screen , to achieve the effect of easy filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Catalyst preparation

[0052] Take 2g of iron oxide (Fe 2 o 3 ) is raw material (I); Take by weighing 16.62g ferric sulfate (Fe 2 (SO 4 ) 3 ·XH 2 O, containing Fe21%), 1.17g potassium sulfate (K 2 SO 4 ), 1.17g copper sulfate (CuSO 4 Anhydrous), 1.03g zinc sulfate (ZnSO 4 ·7H 2 O) is the raw material (II), and it is mixed evenly and added to a ball mill tank (volume 20L, 120 rpm, 15 φ35mm balls, 30 φ25mm balls) for ball milling for 1h, separate the balls, collect the product, and obtain the obtained product Needed catalyst, the composition formula of this catalyst composition is:

[0053] Fe 0.08 ·Cu 0.007 · Zn 0.004·K 0.01 ·O 0.49 ·S 0.11

[0054] (2) Catalyst application

[0055] React the above-mentioned oxidation catalyst, glyoxylic acid and guaiacol (or ethyl guaiacol) to obtain the condensed liquid mandelic acid (or ethyl mandelic acid), and put it in a glass oxidation tower of Φ80mm and H1200mm , Air is introduced into the c...

Embodiment 2

[0057] (1) Catalyst preparation

[0058] Take 10g of alumina (Al 2 o 3 ), 5g iron oxide (Fe 2 o 3 ) is raw material (I); Get 1.2g sodium molybdate (Na 2 MoO 4 2H 2 O) and 10g potassium sulfate (K 2 SO 4 ), 6g copper sulfate (CuSO 4 ·5H 2 O), 10g zinc sulfate (ZnSO 4 ·7H 2 O), 35.2g iron sulfate [Fe 2 (SO 4 ) 3 ·XH 2 O], 10.8g magnesium sulfate (MgSO 4 ·7H 2 O) is the raw material (II); mix the raw material (I) and the raw material (II) thoroughly, then put them into a ball mill tank and mill them for 1 hour, separate out the balls, and collect the product as the prepared oxidation catalyst. Its composition formula is:

[0059] Fe 0.2 ·Cu 0.02 · Zn 0.03 · Mg 0.04 ·Mo 0.005 ·Al 0.2 ·K 0.1 ·Na 0.009 ·O 1.84 ·S 0.36

[0060] (2) Catalyst application

[0061] Put the condensed liquid obtained by reacting the catalyst, glyoxylic acid and guaiacol (or ethyl guaiacol) prepared above into a glass oxidation tower with a diameter of φ80mm and H1200mm, an...

Embodiment 3

[0063] (1) Catalyst preparation

[0064] Carry out according to embodiment 2 preparation process. Take 1gFe 2 o 3 Is raw material (I); Then weigh 10gK 2 SO 4 , 6gCuSO 4 ·5H 2 O, 10gZnSO 4 ·7H 2 O, 35.2gFe 2 (SO 4 ) 3 ·XH 2 O, 10.8gMgSO 4 ·7H 2 O, 2gNa 2 MoO 4 2H 2 O is the raw material (II); fully mix the raw material (I) and the raw material (II), mill it with a ball mill for 1 hour, separate the balls, collect the product, and obtain the required catalyst. The composition composition formula of this catalyst is:

[0065] Fe 0.1 ·Cu 0.02 · Zn 0.03 · Mg 0.04 ·Mo 0.008 ·K 0.1 ·Na 0.02 ·O 1.49 ·S 0.20

[0066] (2) Catalyst application

[0067] The application method of the catalyst made above is the same as (2) of embodiment 2. Wherein catalyst, condensation liquid consumption and mandelic acid or ethyl mandelic acid content etc., see the corresponding batch number of embodiment 3 in table 1, table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com