Method for preparing 2,4-toluene dichloride

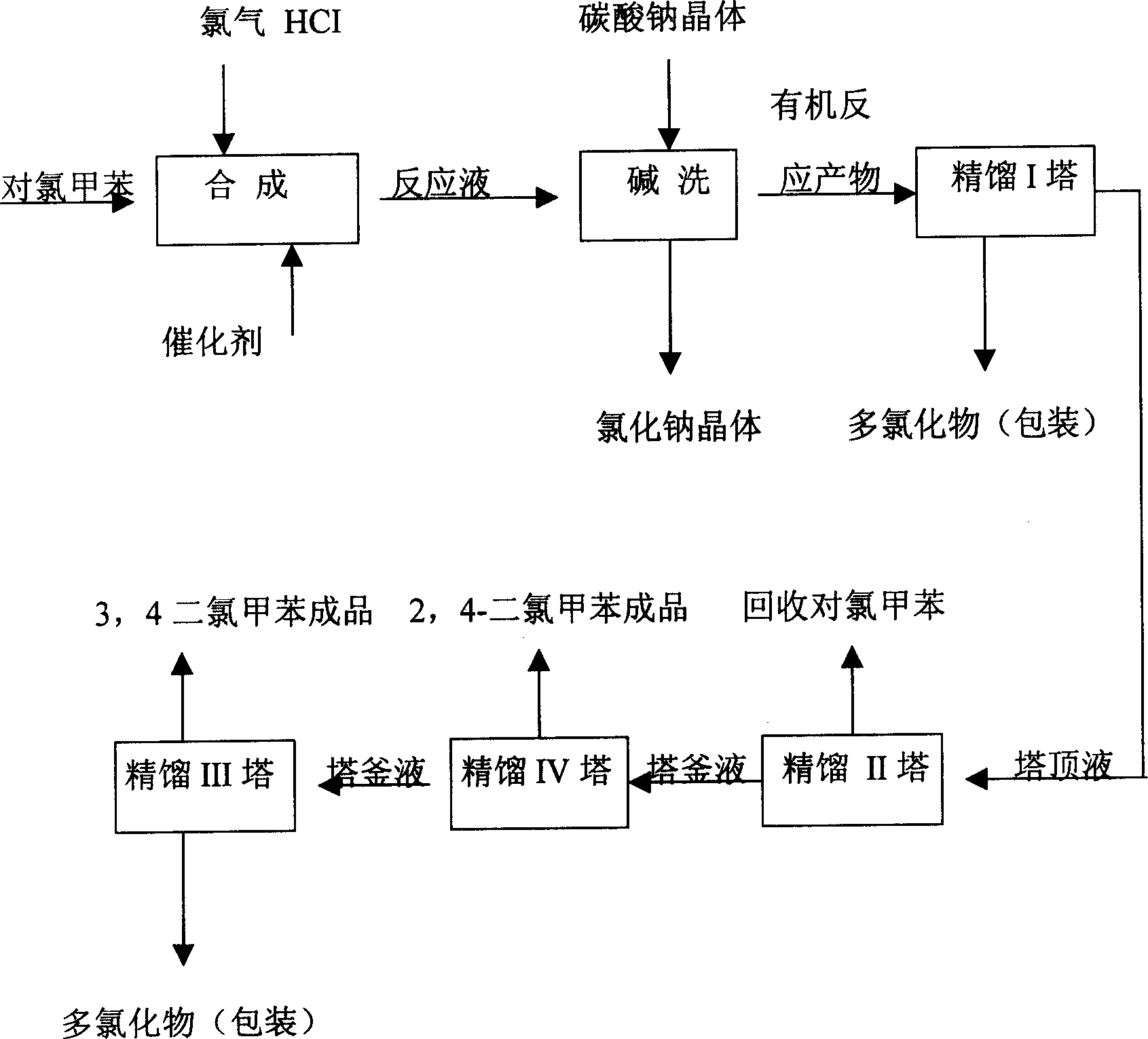

A dichlorotoluene and production method technology, applied in two fields, can solve problems such as unfavorable separation of reaction products and sodium chloride, uneven distribution of chlorine gas at reaction temperature, easy formation of vortex phenomenon in reaction liquid, etc., so as to improve the distribution of chlorine gas, Facilitate separation and shorten reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of production method of 2,4-dichlorotoluene, take p-chlorotoluene, chlorine as raw material, synthesize 2,4-dichlorotoluene through catalytic chlorination, contain synthesis, alkali washing, rectifying steps, add p-chlorotoluene In the reaction kettle with stirring, add catalyst in proportion, heat up, two inlet pipes pass into chlorine gas in p-chlorotoluene simultaneously in proportion, carry out synthesis reaction, its stirring speed is 20 revs / min, the temperature control of synthesis reaction is 35°C, the reaction solution did not form a vortex, and the reaction time was about 13 hours; the reaction product after the reaction was washed with sodium carbonate crystals containing crystal water as an alkali cleaning agent in an alkali cleaning tank, and the reaction product after alkali washing showed obvious Layering, the upper layer is the organic reaction product, the lower layer is the sodium chloride crystal containing crystal water, the organic reaction pr...

Embodiment 2

[0019] A kind of production method of 2,4-dichlorotoluene, take p-chlorotoluene, chlorine as raw material, synthesize 2,4-dichlorotoluene through catalytic chlorination, contain synthesis, alkali washing, rectifying steps, add p-chlorotoluene In the reaction kettle with stirring, add the catalyst in proportion, heat up, and three inlet pipes feed chlorine gas into p-chlorotoluene in proportion to carry out the synthesis reaction. The stirring speed is 30 rpm, and the temperature of the synthesis reaction is controlled at 45 ℃, the reaction solution did not form a vortex, and the reaction time was about 13 hours; the reaction product after the reaction was washed in the alkali washing tank with sodium carbonate crystals containing crystal water as the alkali washing agent, and the reaction product after alkali washing showed obvious separation. layer, the upper layer is the organic reaction product, and the lower layer is the sodium chloride crystal containing crystal water, the...

Embodiment 3

[0021] A kind of production method of 2,4-dichlorotoluene, take p-chlorotoluene, chlorine as raw material, synthesize 2,4-dichlorotoluene through catalytic chlorination, contain synthesis, alkali washing, rectifying steps, add p-chlorotoluene In the reaction kettle with stirring, add catalyzer in proportion, heat up, four inlet pipes pass into chlorine gas in p-chlorotoluene simultaneously in proportion, carry out synthetic reaction, its stirring speed is 40 rev / min, and the temperature control of synthetic reaction is At 40°C, the reaction solution did not form a vortex, and the reaction time was about 13 hours; the reaction product after the reaction was washed in the alkali washing tank with sodium carbonate crystals containing crystal water, and the reaction product after alkali washing showed obvious Layering, the upper layer is the organic reactant containing 2,4-dichlorotoluene, the lower layer is the sodium chloride crystal containing crystal water, the organic reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com