Machine cleanable woolen fabrics with nano structure on wool fiber surface and preparation thereof

A nanostructure, wool fiber technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of resource loss and economic damage, and achieve the effect of no environmental pollution, no waste water discharge, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

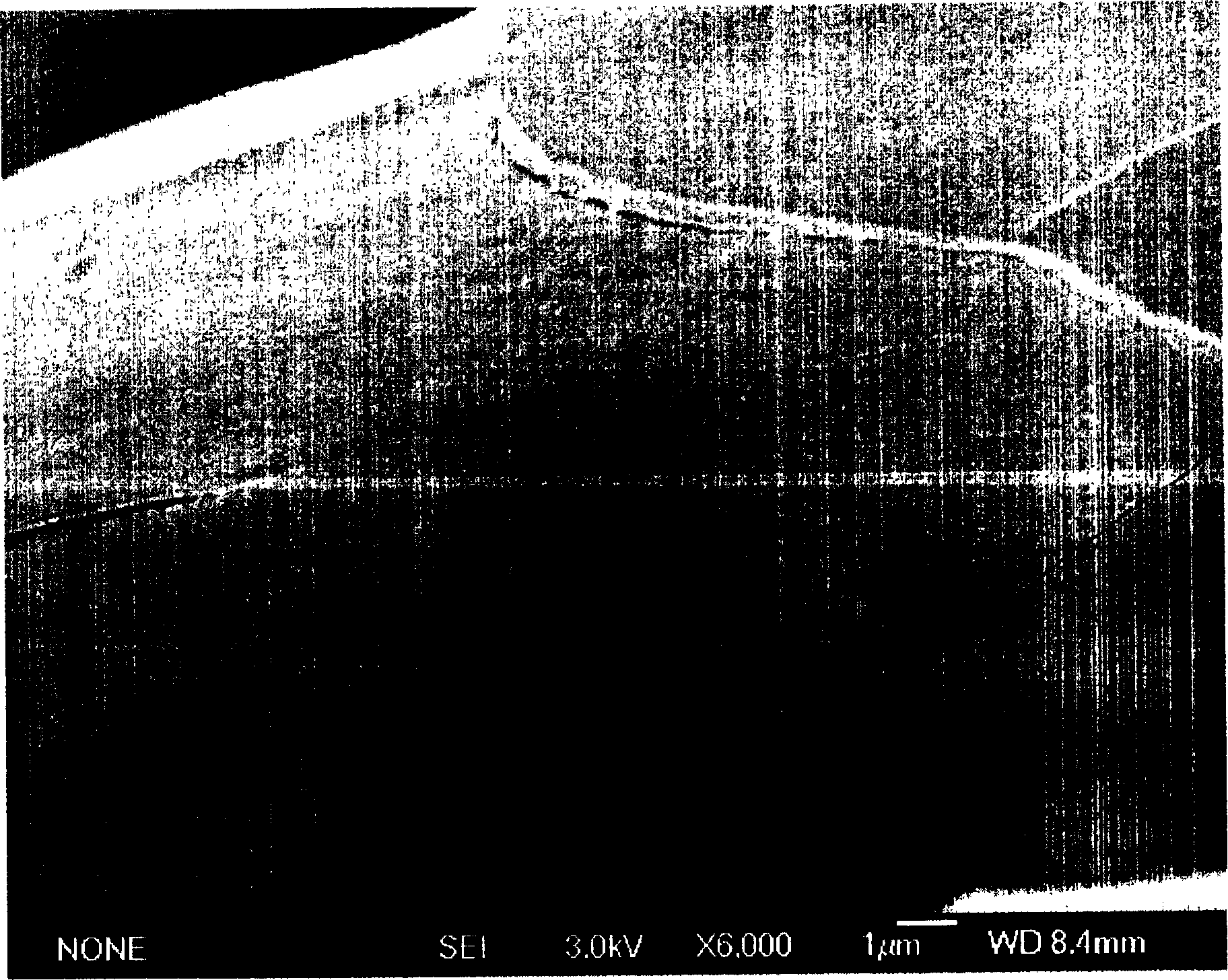

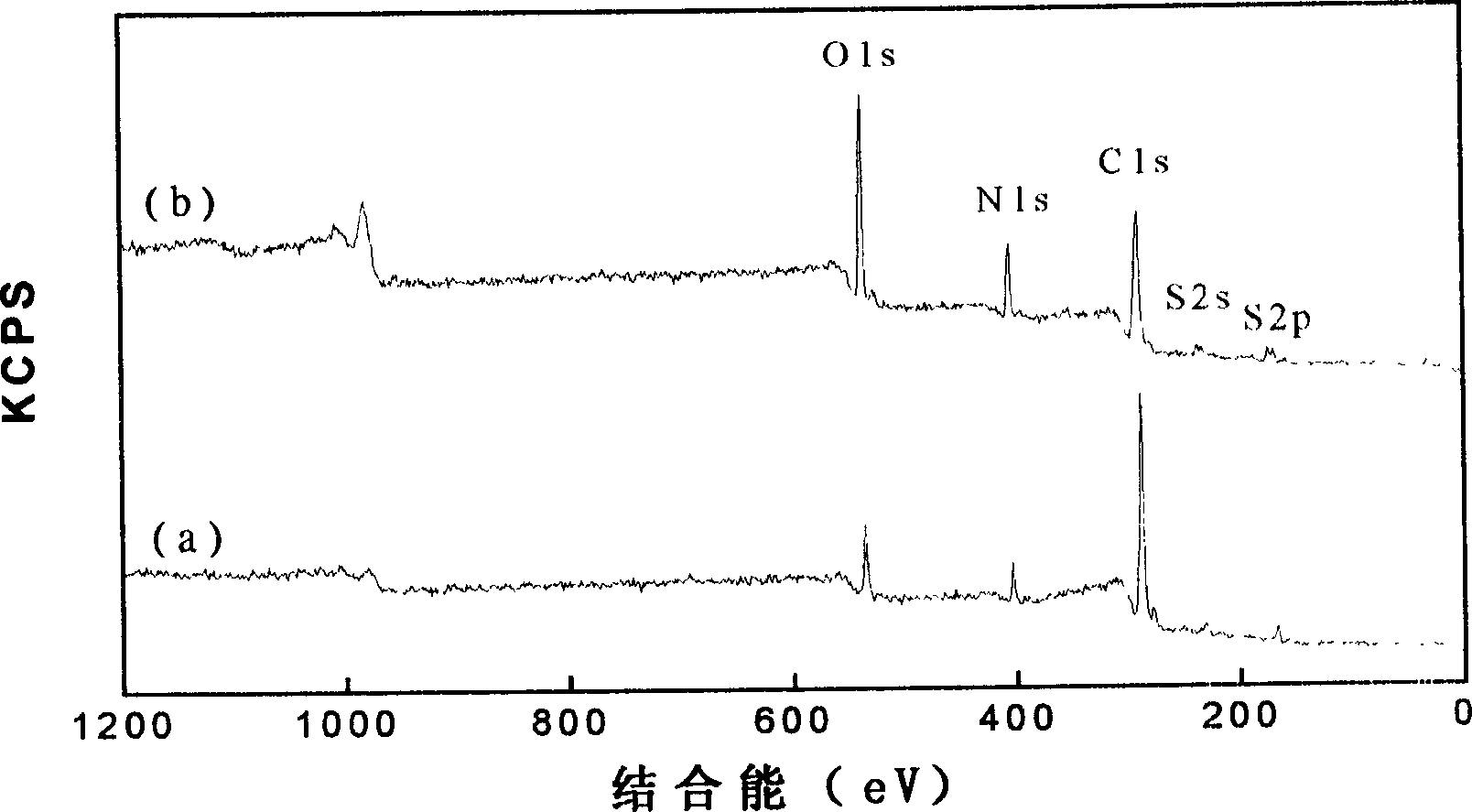

[0032] Low-temperature plasma treatment: put the woolen fabric into the low-temperature plasma reaction chamber, vacuumize, and when the pressure in the reaction chamber reaches 4Pa, start to introduce air to balance the vacuum degree in the reaction chamber at 26Pa, then perform glow discharge, and use 100W power for 30min discharge treatment.

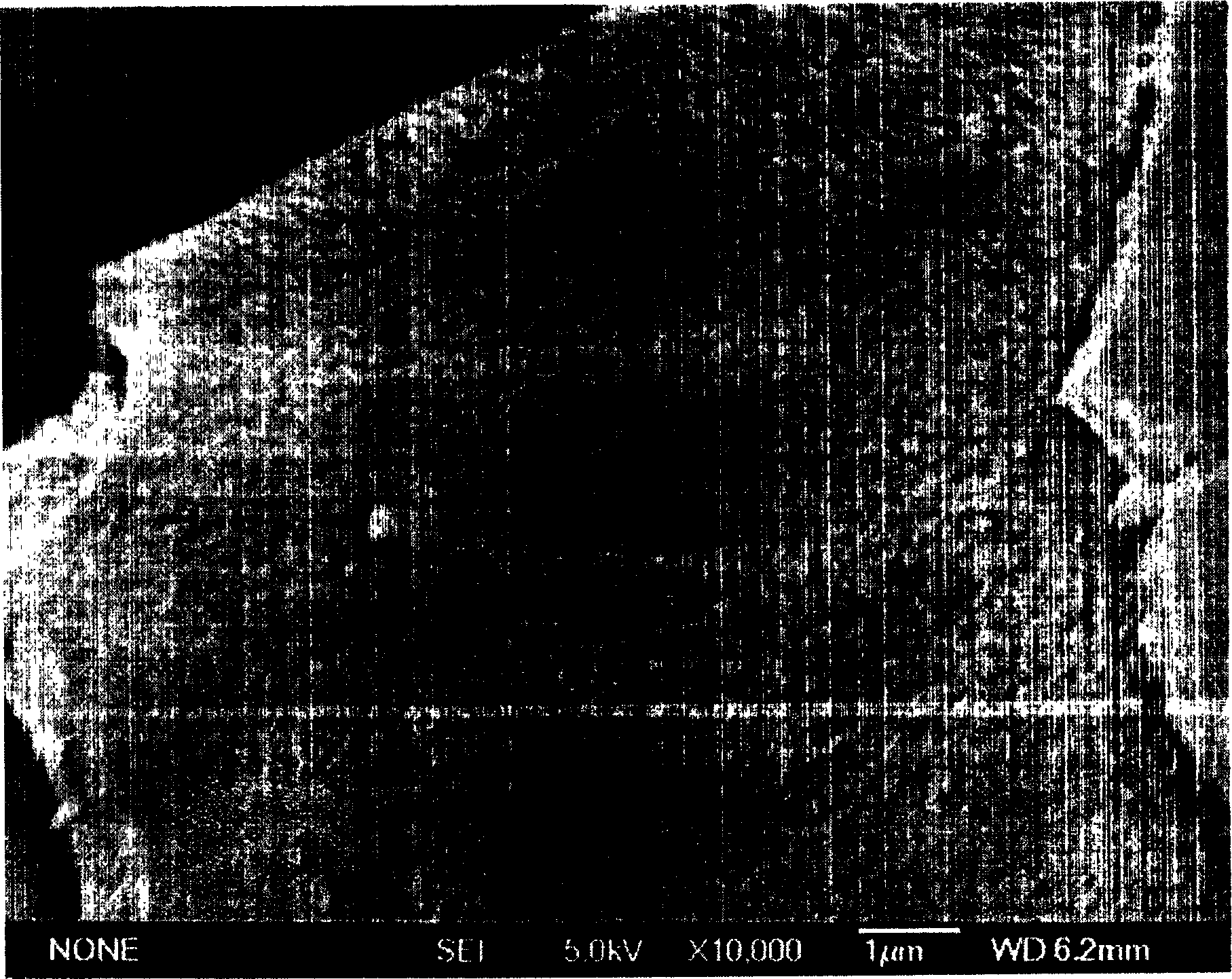

[0033] Finishing process: immerse the above-mentioned low-temperature plasma-treated wool fabric in the finishing solution containing 2g / L chitin at 35°C for 30 minutes, take out the squeezed liquid, and the squeezed liquid rate is 90%, and then pre-baked at 90°C for 8 minutes , and baked at a temperature of 130° C. for 2 minutes.

Embodiment 2

[0035] Low-temperature plasma treatment: the wool fabric was placed in a low-temperature plasma reaction chamber, and the same low-temperature plasma treatment as in the above-mentioned embodiment 1 was performed.

[0036] Finishing process: except that 30 g / L of AV-910 amino-modified silicon softener was further included in the finishing liquid, the same finishing as in the above-mentioned Example 1 was carried out.

Embodiment 3

[0038] Low-temperature plasma treatment: low-temperature plasma treatment: put the wool fabric into the low-temperature plasma reaction chamber, vacuumize, and start to introduce oxygen when the pressure in the reaction chamber reaches 7Pa to balance the vacuum degree in the reaction chamber at 160Pa, and then perform glow discharge. Discharge treatment with 50W power for 60min.

[0039] Finishing process: immerse the above-mentioned low-temperature plasma-treated wool fabric in a finishing solution containing 2.5g / L chitin at 40°C for 25 minutes, take out the squeezed liquid, and the squeezed liquid rate is 80%, and then pre-dry it at a temperature of 80°C 10min, and bake at 110°C for 3min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com