Method for snthesizing isomery polyethenoxy ether carboxylate

A technology of polyoxyethylene ether carboxylate and polyoxyethylene ether, which is applied in the field of synthesis of anionic surfactants, can solve the problems of large equipment investment and many side reactions, and achieve simple equipment, less side reactions, and production process conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

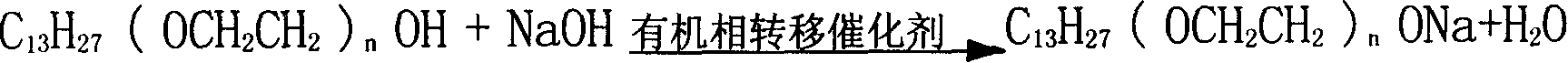

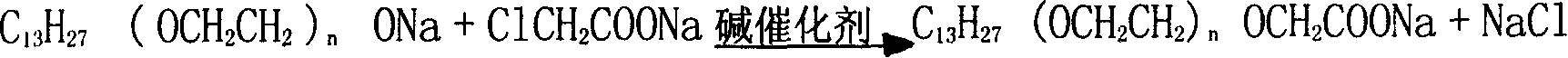

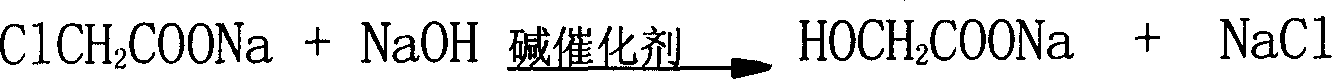

Method used

Image

Examples

Embodiment Construction

[0014] Add 160 parts of isomeric tridecyl alcohol polyoxyethylene ether in the reaction kettle, add 10 parts of sodium hydroxide ground into powder under stirring, 40 parts of acetone as the organic phase transfer catalyst, under the protection of nitrogen, control the reaction temperature 30 -35°C, reflux under reaction conditions for 5.0 hours. After the reflux, 28 parts of sodium chloroacetate and 12 parts of sodium hydroxide were slowly added, and the temperature was raised slowly after the addition. Under the protection of nitrogen, the temperature was controlled at 50-55°C, and the reaction time of heat preservation was 3.0 hours. After the reaction, add hydrochloric acid to neutralize to PH = 7.0-8.0, dry under reduced pressure to remove the water and acetone solvent, filter with hot ethanol to remove the salt, and then remove the ethanol to obtain isomeric tridecanol polyoxyethylene ether Carboxylate, the yield of its target product measured by rotating thin-layer chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com