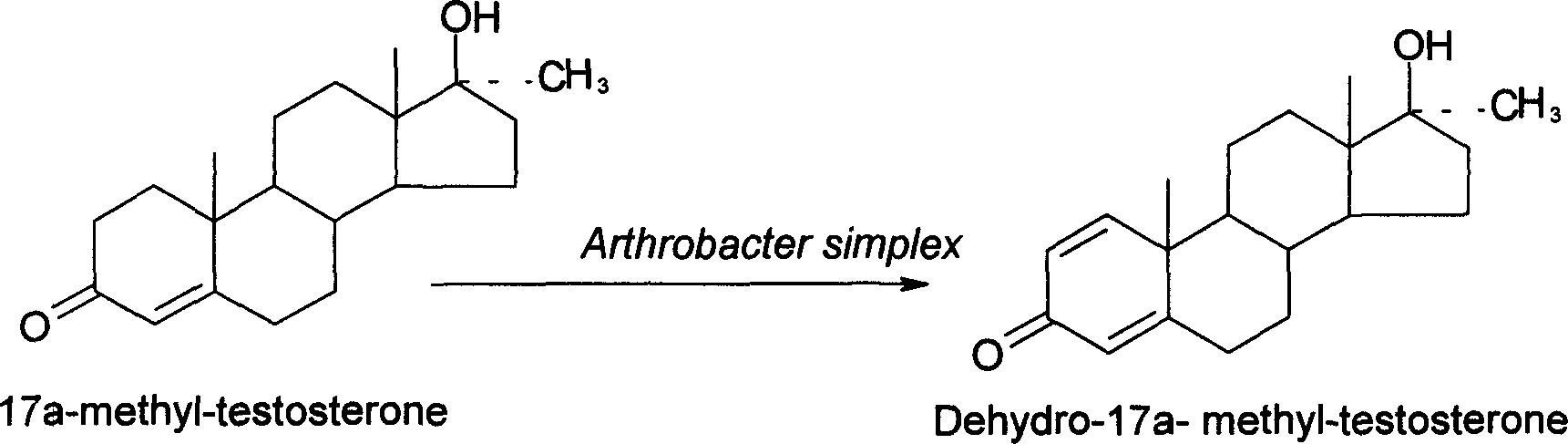

Preparation technique for producing mayandrosteron through microbial conversion method

A technology of microbial transformation and metandrone, applied in the direction of fermentation, etc., can solve the problems of complex operation, low feeding concentration, small scale, etc., and achieve the effect of simple operation process, slight environmental pollution, and increased yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

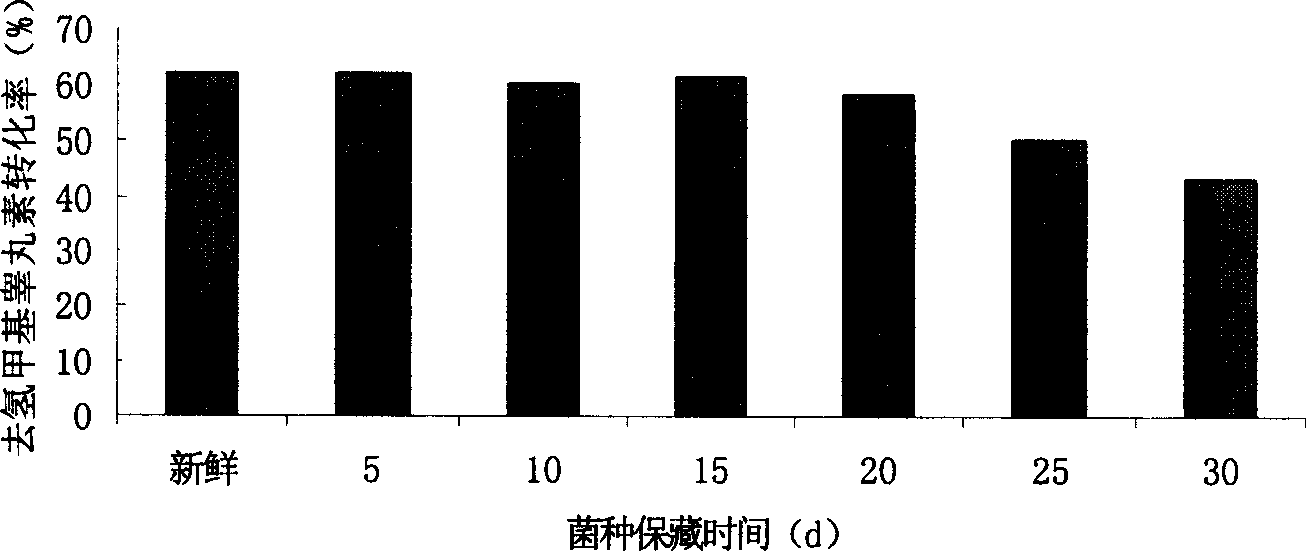

[0044] The production strain is Arthrobacter simplex preserved in the Department of Applied Microbiology of Tianjin University of Science and Technology, numbered BY31250. The production strain was cultured on an agar slant at a constant temperature of 30°C for 2 days, and stored at 4°C for 5 days for use. Wherein, the liquid used for making the bacterial seed suspension is sterile water or fresh seed culture medium, and the sterilization condition is: 121° C. for 20 to 25 minutes.

[0045] The seed medium consists of carbon source, nitrogen source and inorganic phosphorus, namely:

[0046] Glucose 8g / L

[0047] Corn syrup 10g / L

[0048] Yeast extract 3g / L

[0049] K H 2 PO 4 1.5g / L

[0050] pH 6.4

[0051] The prepared seed suspension was added to the above-mentioned seed medium, and the sterilization condition was 121°C for 25 minutes; the shaker rotated at 60r / min, and cultured at 30°C for 22h to obtain a seed culture suitable for inoculation.

[00...

Embodiment 2

[0063] Use the fresh seed slant, that is, the production strain to be used directly after 2 days of constant temperature cultivation at 30°C on the agar slant, and prepare the bacterial suspension with sterile water. Described in one-level seed culture, secondary fermentation culture example 1. The substrate 17α-methyltestosterone (17α-methyltestosterone) was pulverized to a particle size of 14-16μ, and was quickly put into the cultured fermentation broth under aseptic conditions, and the feeding amount was 1.2g / L fermentation broth volume, and the relative In the industrial ethanol of 3% of fermented liquid volume, transformation condition is described in example 1. After 9 hours of transformation, 4% industrial ethanol relative to the volume of the fermentation broth was added; after 48 hours of transformation, samples were taken to control the end point by TLC and HPLC.

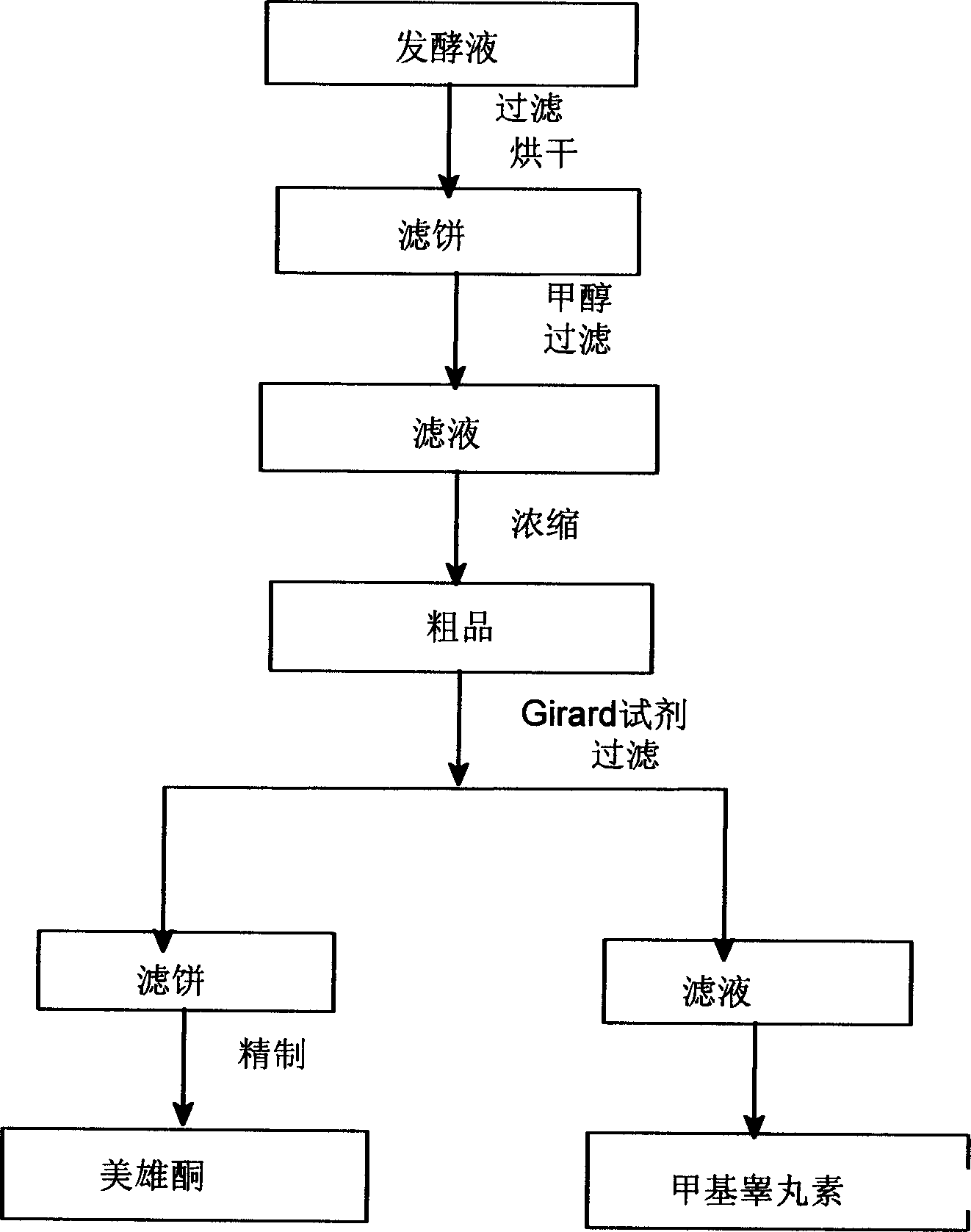

[0064] After the conversion, the extraction and separation of the fermented liquid are the same as des...

Embodiment 3

[0066] Use the fresh seed slant, that is, the production strain to be used directly after 2 days of constant temperature cultivation at 30°C on the agar slant, and prepare the bacterial suspension with sterile water. Described in one-level seed culture, secondary fermentation culture example 1.

[0067] Pulverize the recovered substrate with a particle size of 14-16 μ, quickly put it into the cultured fermentation broth under aseptic conditions, and the feeding amount is 2.0g / L fermentation broth volume, and add 3% industrial alcohol relative to the fermentation broth volume, The transformation conditions were as described in Example 1. After 8 hours of transformation, 4% industrial ethanol relative to the volume of the fermentation broth was added; after 24 hours of transformation, samples were taken to control the end point by TLC and HPLC.

[0068] After the conversion, the extraction and separation of the fermented liquid are the same as described in Example 1, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com