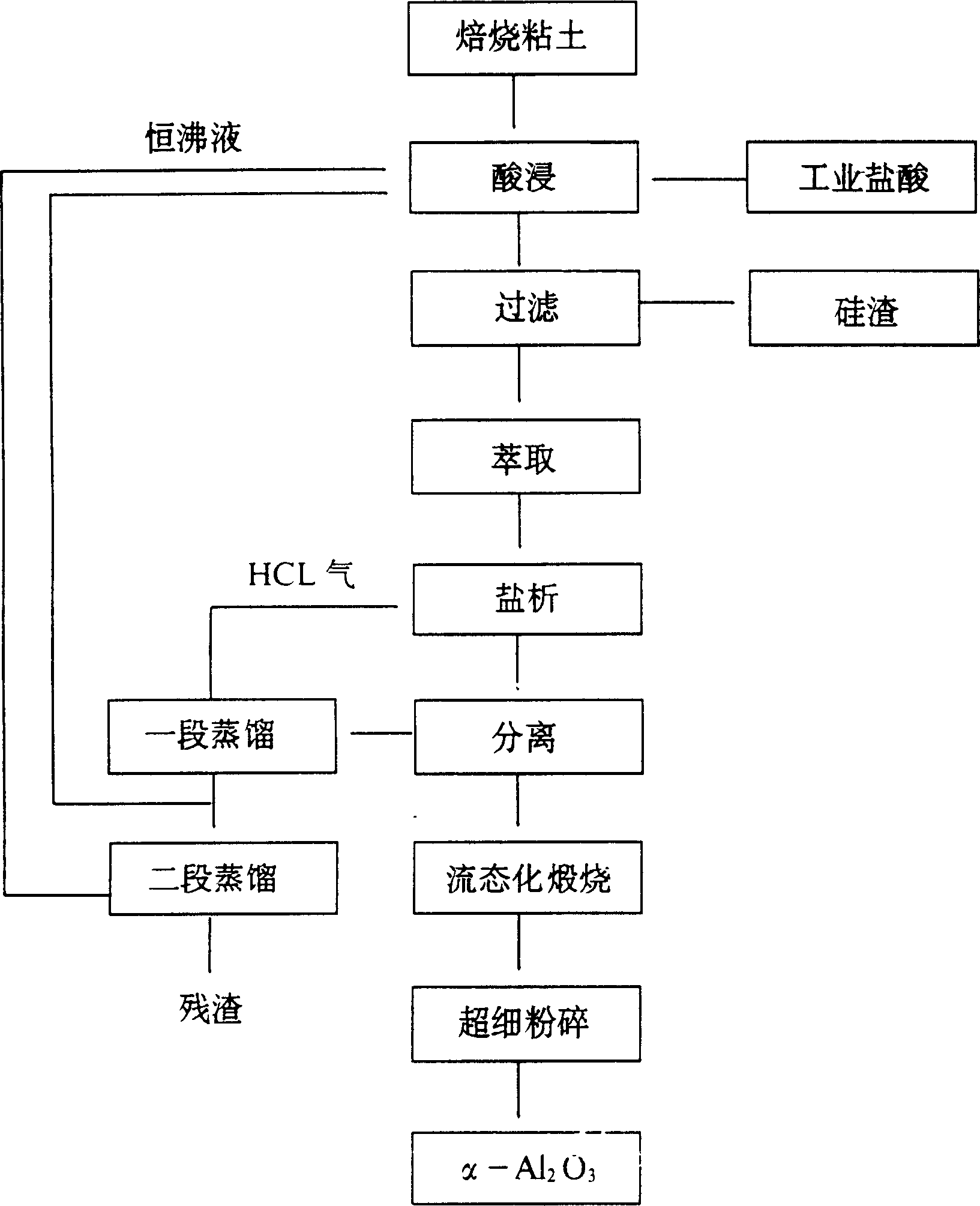

Technological process for preparing submicron alumina using improved salting out method

A process method and sub-micron technology, applied in chemical instruments and methods, improvement of process efficiency, inorganic chemistry, etc., can solve the problems of large distillation volume and high energy consumption for cooling and salting out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with example the present invention is described in further detail.

[0013] Crush the kaolinite-type clay to 60-100 meshes, and roast at 700-760°C for 3 hours. Use circulating distillate, hydrochloric acid azeotropic liquid, and supplementary industrial hydrochloric acid to leach for 2 hours at 109°C, filter with a frame filter press, discharge the silicon slag from the stockyard, and extract the leachate with an organic solvent. Pass hydrogen chloride gas into the extracted liquid to carry out salting-out, the free acid at the end point of salting-out is 350-390g / l, the salting-out temperature is 60-25°C, and then filter, and the crystalline aluminum chloride is heated in a fluidized suspension furnace at 1220-1300 Calcination at ℃, phase inversion, salting-out mother liquor is sent to distillation, the final temperature of one distillation is 109-110 ℃, the distilled hydrogen chloride gas is sent to salting-out, after distillation, the liquid frac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com