Method for making polysilicon film

A technology of polysilicon thin film and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as inconsistency in grain size, poor uniformity of polysilicon thin film, and difficult control of excimer laser energy density, etc., to achieve The effect of good surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

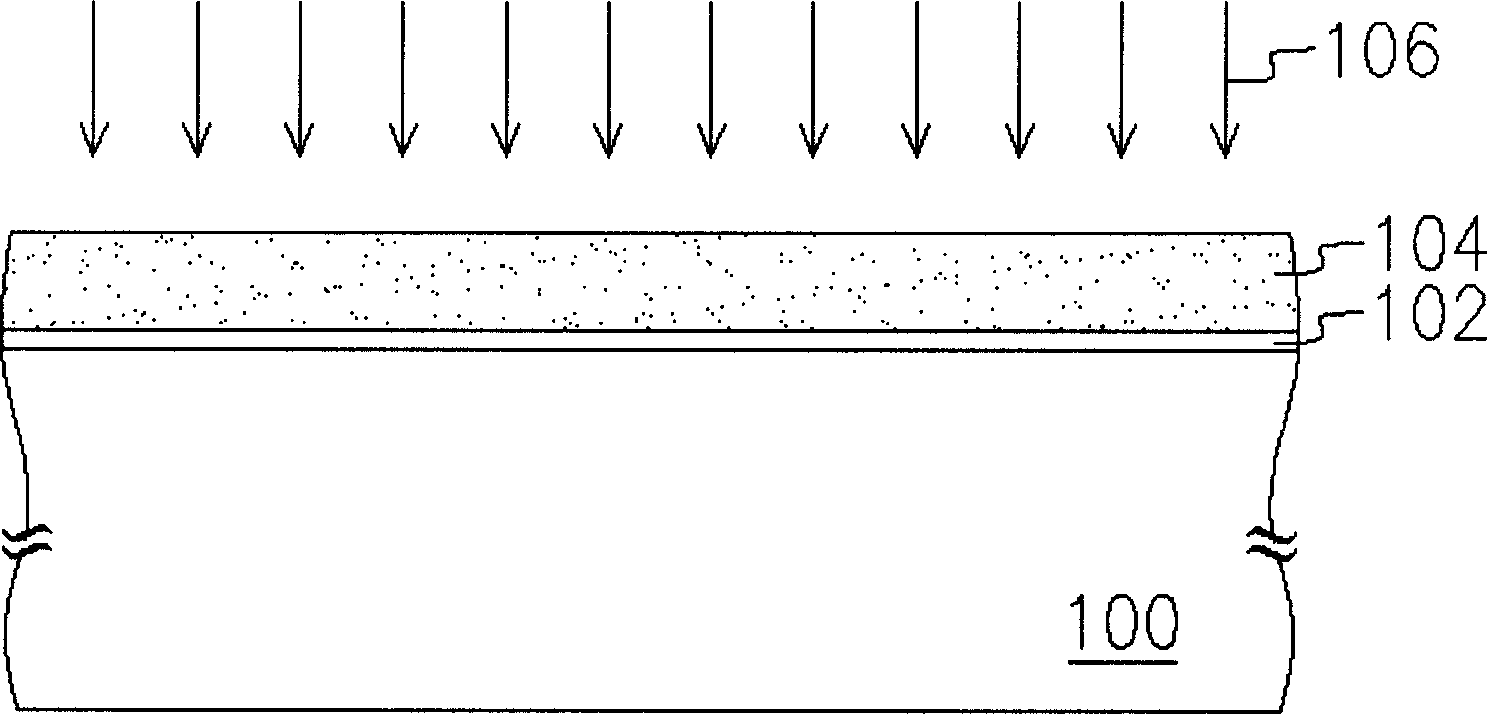

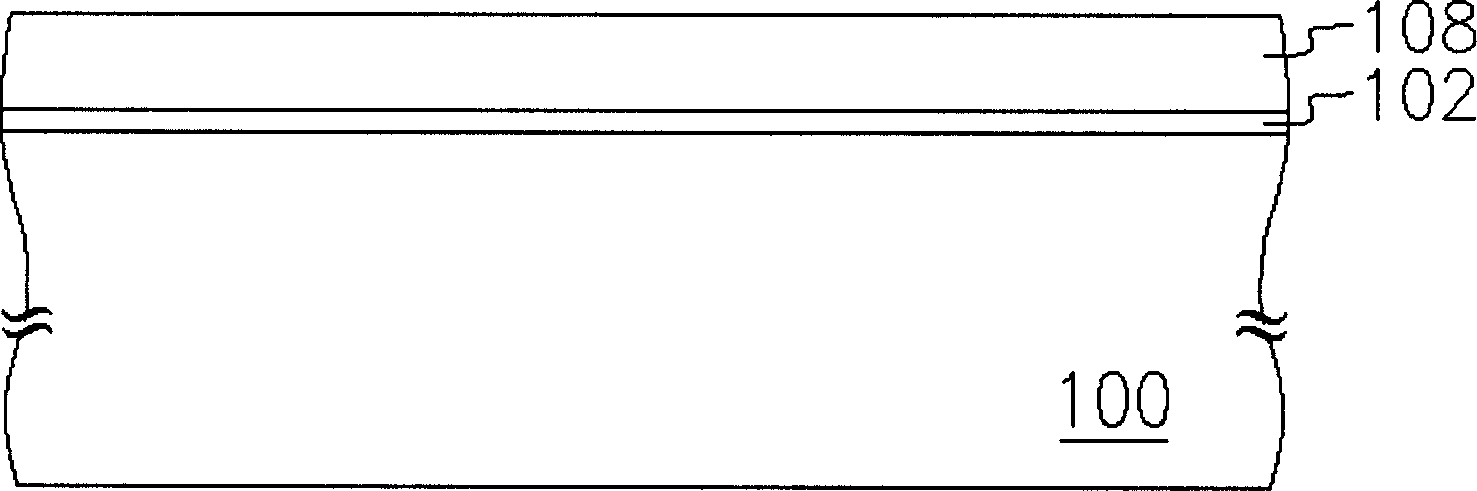

[0034] Please refer to Figure 2A to Figure 2F , which is a cross-sectional view of the manufacturing process of the polysilicon thin film according to the first embodiment of the present invention.

[0035] First, please refer to Figure 2A , providing a substrate 200, such as a silicon wafer, a glass substrate or a plastic substrate, forming an insulating layer 202 on the substrate 200, the material of the insulating layer 202 is, for example, silicon dioxide, and the formation method is, for example, A silicon dioxide layer is formed on the substrate 200 by Low Pressure Chemical Vapor Deposition (LPCVD), Plasma Enhanced Chemical Vapor Deposition (PECVD) or sputtering (Sputter) . Next, a layer of amorphous silicon layer 204 is formed on the insulating layer 202. The amorphous silicon layer 204 is formed by, for example, low pressure chemical vapor deposition, plasma enhanced chemical vapor deposition or sputtering, wherein the formed The amorphous silicon layer 204 has a ...

no. 2 example

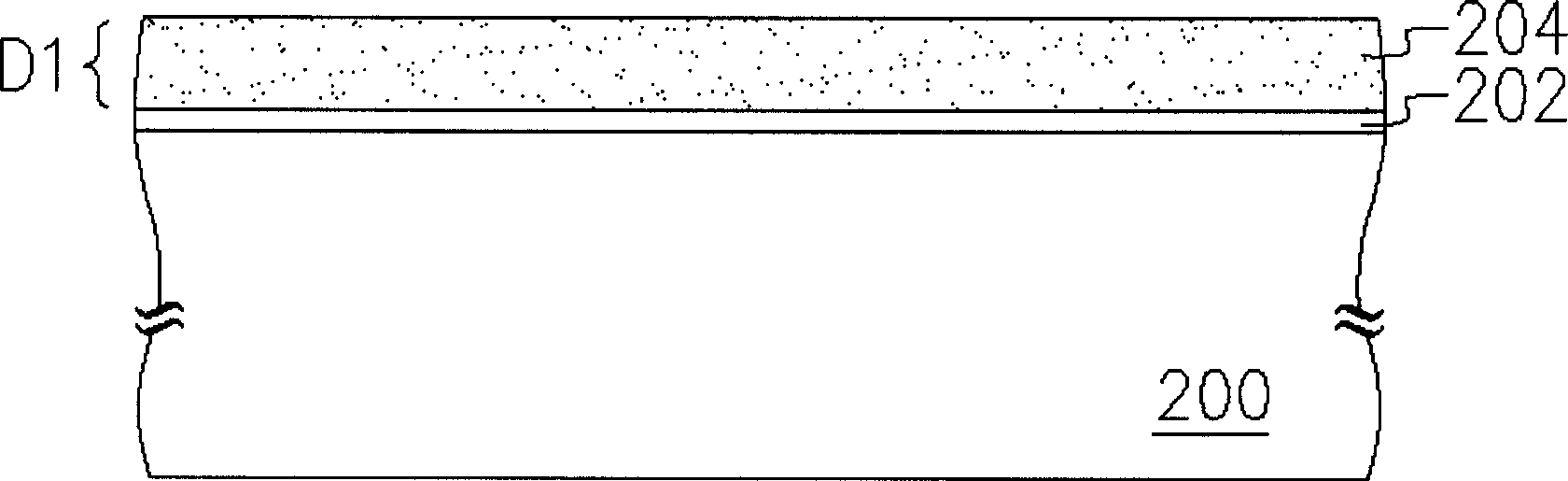

[0045] Please refer to Figure 3A to Figure 3G , which is a cross-sectional view of the manufacturing process of the polysilicon thin film according to the second embodiment of the present invention.

[0046] First, please refer to Figure 3A , providing a substrate 300, such as a silicon wafer, a glass substrate or a plastic substrate, forming an insulating layer 302 on the substrate 300, wherein the material of the insulating layer 302 is, for example, silicon dioxide, and the forming method is, for example, A silicon dioxide layer is formed on the substrate 300 by low pressure chemical vapor deposition, plasma enhanced chemical vapor deposition or sputtering. Next, a layer of amorphous silicon layer 304 is formed on the insulating layer 302. The amorphous silicon layer 304 is formed by, for example, low-pressure chemical vapor deposition, plasma-enhanced chemical vapor deposition, or sputtering, wherein the formed The amorphous silicon layer 304 has a thickness D4, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com