Weak alkaline circulation water treating and anti-corrosion method for water cooling generator static wire stick

A generator stator and stator bar technology, applied in the direction of ion exchange water/sewage treatment, etc., can solve the problems of unfavorable safe and stable operation, corrosion of copper wire bars, etc., achieve good social and economic benefits, slow down corrosion, and save medicines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

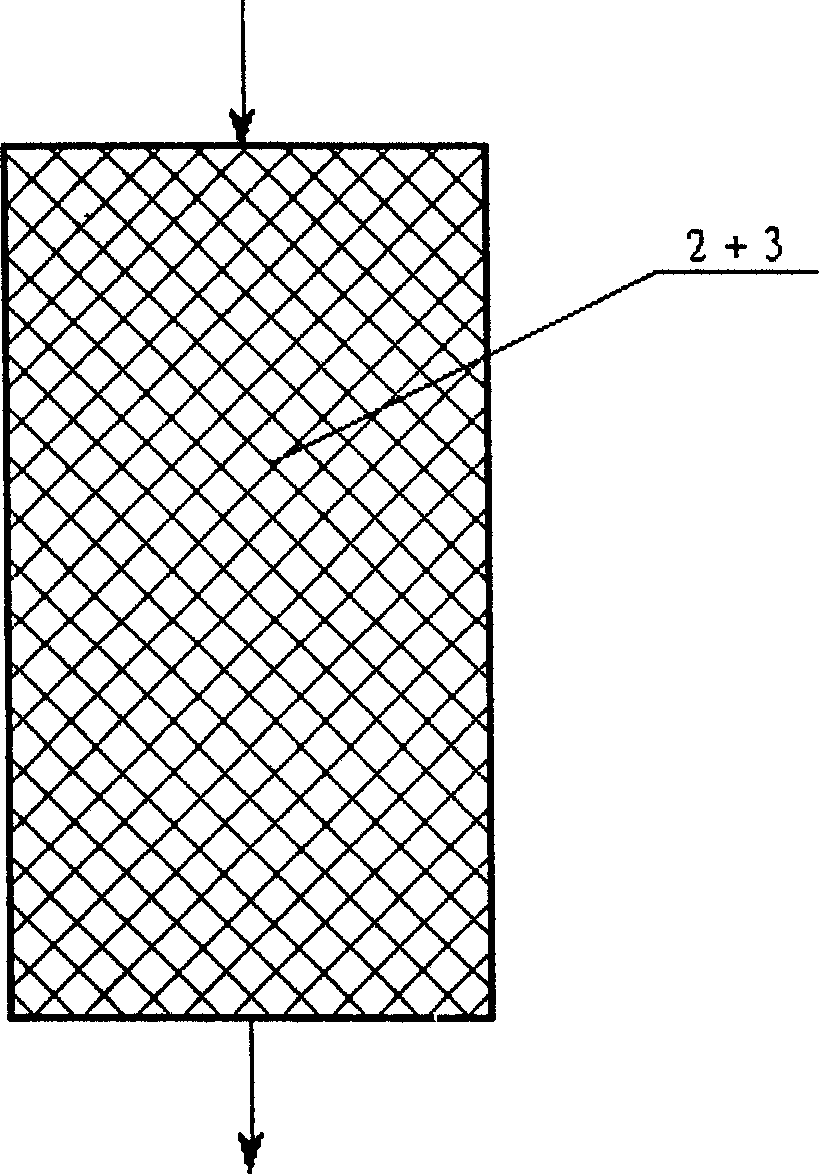

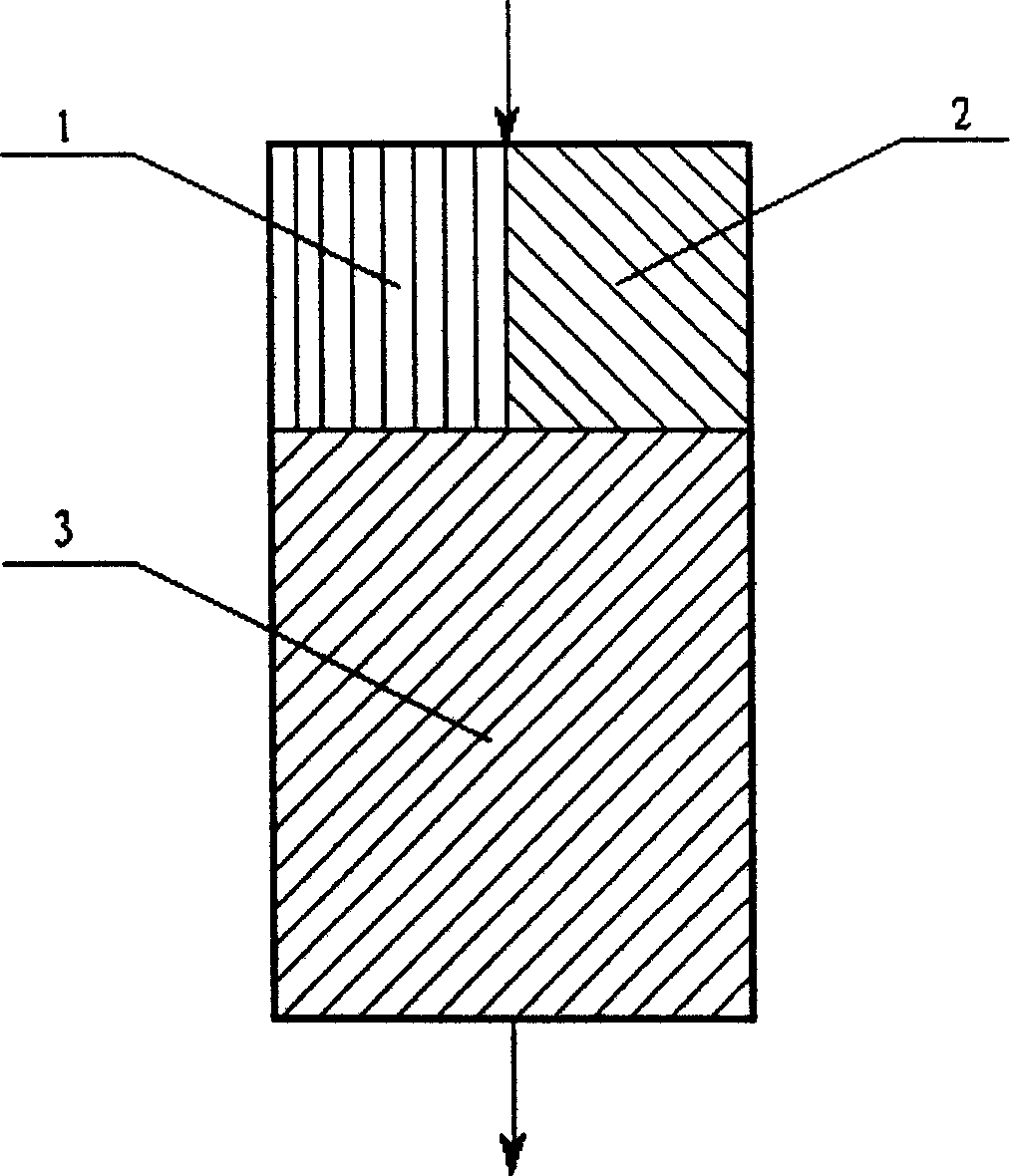

[0017] The bed structure of the micro-alkaline circulation processor is: divided into upper and lower layers, the upper layer consists of 40 kg of H-type strong acidic supergel styrene-based uniform particle resin 001×7MB and 10 kg of Na-type strong acidic supergel The styrene-based uniform particle resin 001×7MB is formed in parallel, and the lower layer is composed of 100 kg of OH-type strong basic macroporous styrene-based uniform particle resin D201.

[0018] When the internal cooling water of the generator flows through the slightly alkaline circulation processor, the following ion exchange reactions will occur:

[0019]

[0020]

[0021] (M is copper, iron, ammonium and other cations, n is the charge number of cation M)

[0022]

[0023] (A is anion such as chlorine, bicarbonate, etc., m is the charge number of anion A)

[0024] According to the above ion exchange reaction formula, as long as there are traces of impurity ions such as copper, iron, a...

Embodiment 2

[0026] The selected Na type strongly acidic cation exchange resin 1, H type strongly acidic cation exchange resin 2, and OH type strongly basic anion exchange resin 3 of this embodiment are respectively D001, D001, D201, and the consumption is respectively 15 kilograms, 75 kilograms, 180 kg.

Embodiment 3

[0028] The selected Na-type strongly acidic cation exchange resin 1, H-type strongly acidic cation-exchange resin 2, and OH-type strongly basic anion-exchange resin 3 of this embodiment are respectively D001, D001, 201×7MB, and the dosages are respectively 10 kilograms, 50 kg, 120 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com