Preparation process for nano composite of polyester / clay

A technology of nanocomposite materials and clay, which is applied in the field of preparation of PET/clay nanocomposite materials, and can solve problems such as poor thermal stability and uneven dispersion of montmorillonite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

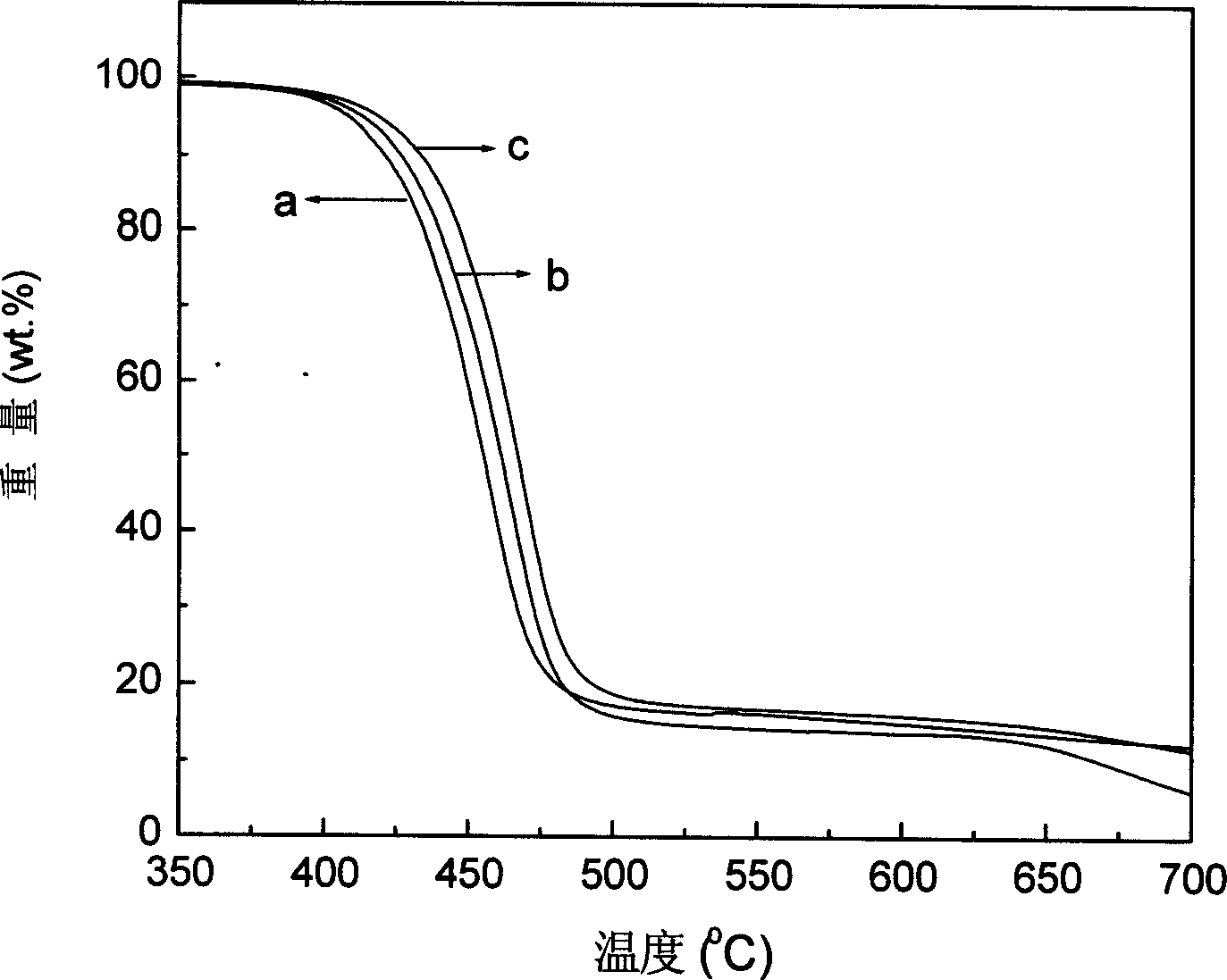

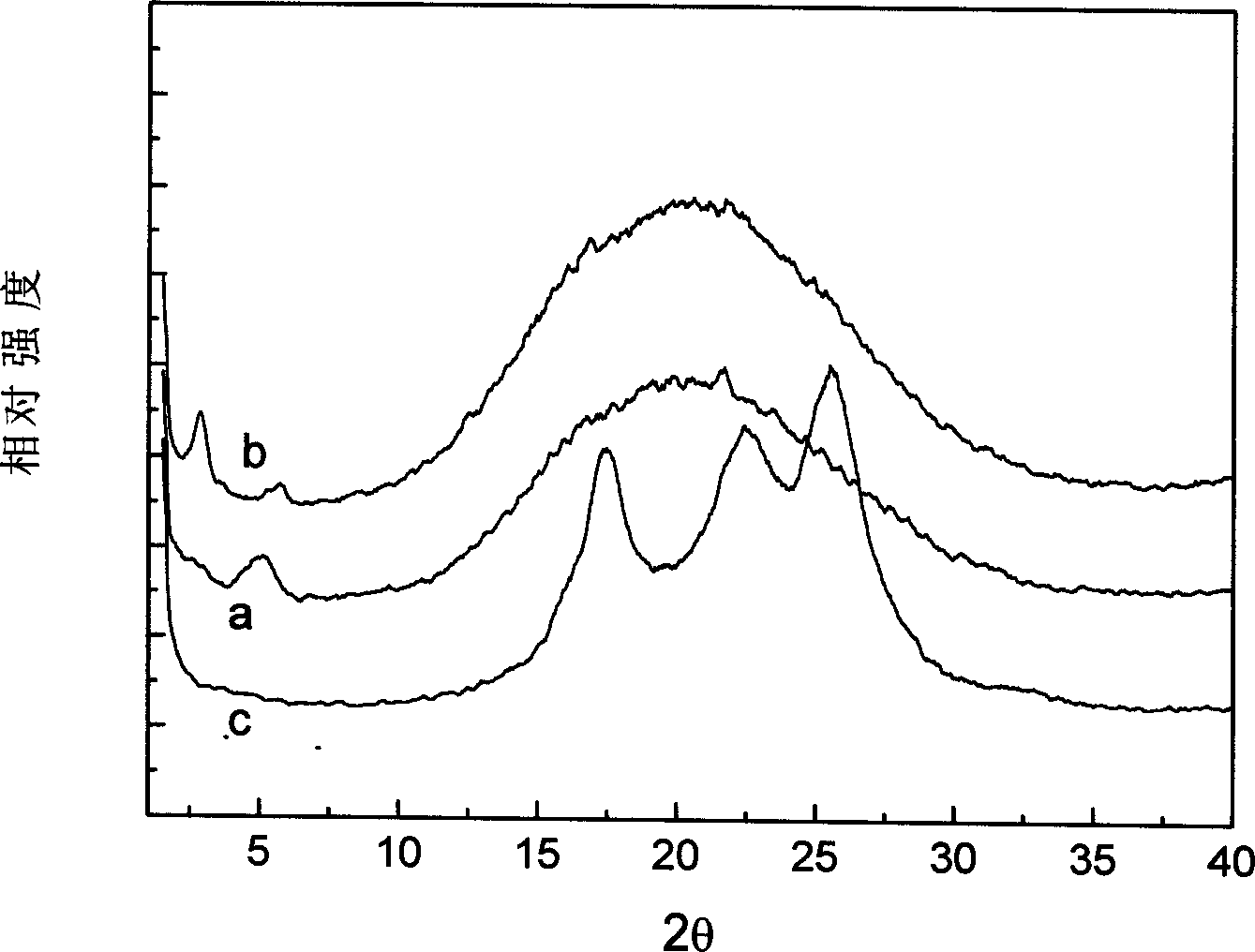

[0017] Add 10.0 g of montmorillonite with a cation exchange capacity of 100 meq / 100 g to 150 g of ethylene glycol, heat to 80° C., and stir at high speed to obtain a suspension.

[0018] Dissolve 0.4g of antimony acetate in 40g of ethylene glycol heated to 80°C to obtain a solution. Slowly add the solution to the above suspension, stir at 80°C for 4 hours, cool to room temperature naturally, centrifuge to obtain a precipitate, wash with ethylene glycol three times, the distance between the layers of montmorillonite expands from 1.2nm to 1.7nm, indicating that Sb 3+ Has been exchanged between layers of montmorillonite.

[0019] Disperse the above wet montmorillonite evenly in 200g of water, dissolve 3.2g of hexadecyltriphenylphosphine bromide in 100g of water, add it to the montmorillonite water suspension, stir at 90°C for 4 hours, centrifuge and wash with distilled water Repeatedly until no bromide ions are detected with 0.1N silver nitrate solution, the product is dried an...

Embodiment 2

[0022] Add 8.0 g of montmorillonite with a cation exchange capacity of 110 meq / 100 g to 120 g of ethylene glycol, heat to 80° C., and stir at high speed to obtain a suspension.

[0023] Dissolve 0.3g of antimony acetate in 15g of ethylene glycol heated to 80°C to obtain a solution. Slowly add the solution to the above suspension, stir at 80°C for 4 hours, cool to room temperature naturally, centrifuge to obtain a precipitate, wash with ethylene glycol three times, the distance between the layers of montmorillonite expands from 1.2nm to 1.7nm, indicating that Sb 3+ Has been exchanged between layers of montmorillonite.

[0024] Disperse the above wet montmorillonite evenly in 200g of water, dissolve 2.1g of hexadecylpyridinium bromide in 100g of water, add it to the montmorillonite water suspension, stir at 90°C for 4 hours, then centrifuge and wash with distilled water for several times until 0.1N silver nitrate solution was used to detect the absence of bromide ions, and the...

Embodiment 3

[0027] Add 15.0 g of montmorillonite with a cation exchange capacity of 90 meq / 100 g to 250 g of ethylene glycol, heat to 80° C., and stir at high speed to obtain a suspension.

[0028] Dissolve 0.7g of antimony acetate in 60g of ethylene glycol heated to 80°C to obtain a solution. The solution was slowly added to the above suspension, stirred at 80°C for 4 hours, cooled to room temperature naturally, centrifuged to obtain a precipitate, and washed three times with ethylene glycol.

[0029] Disperse the above wet montmorillonite evenly in 300g of water, dissolve 8.0g of polyvinylpyrrolidone in 100g of water, add it to the montmorillonite water suspension, stir at 90°C for 2 hours, then centrifuge, wash with distilled water several times, and centrifuge the obtained product It is organic montmorillonite powder with catalytic activity, and the interlayer distance of montmorillonite is further enlarged to 3.5nm.

[0030] 100g of BHET and 2.0g of the above-mentioned montmorilloni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com