Adhesive and packing laminated product using the adhesive

一种粘合剂、多元醇的技术,应用在层压制品领域,能够解决粘合强度降低、性能降低、粘合缺乏等问题,达到优异粘合性能、高粘合强度、粘合性能优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

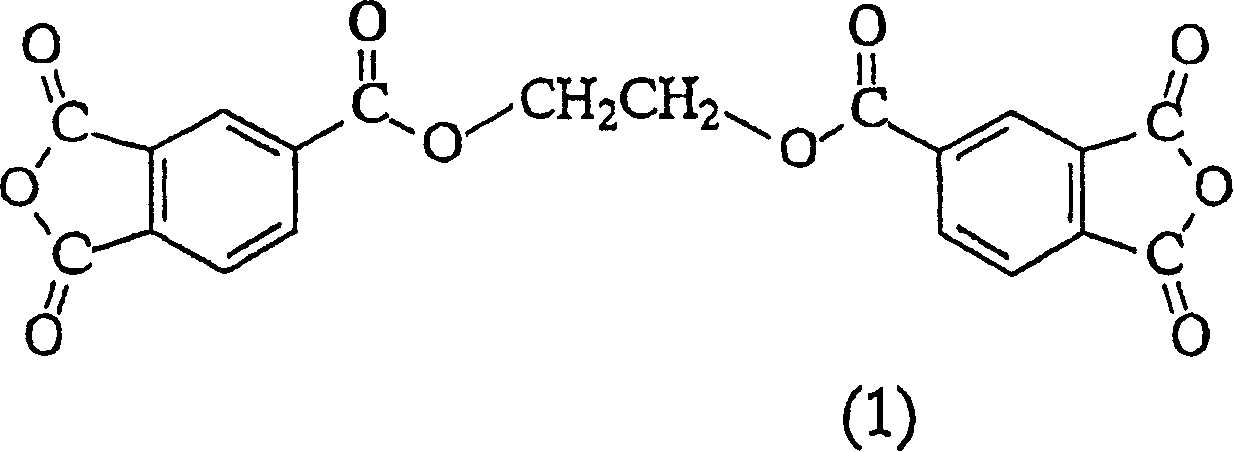

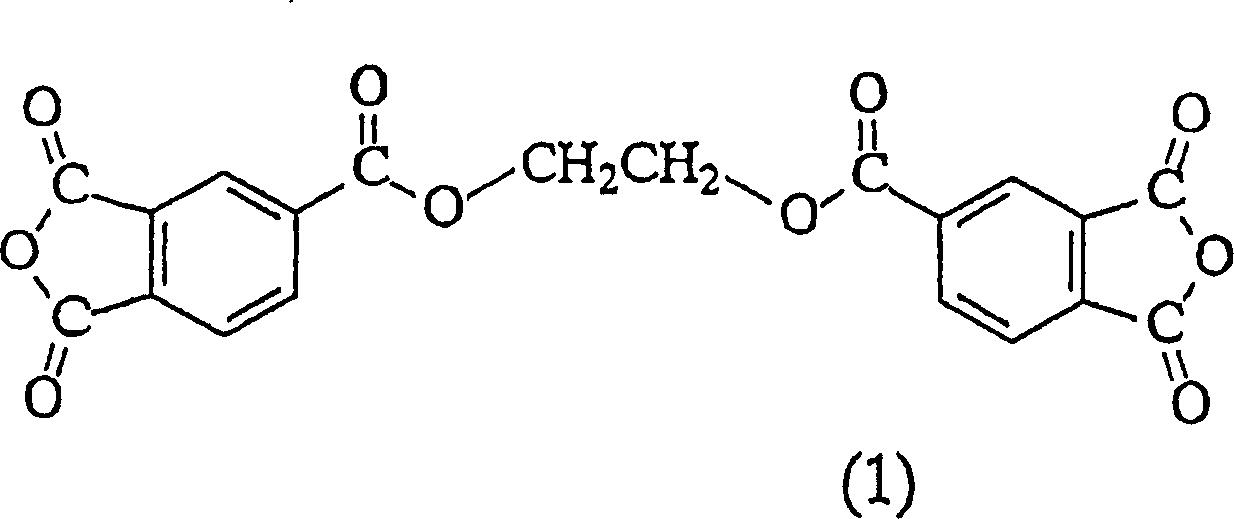

Image

Examples

preparation Embodiment 1-5

[0044] Add 13.28kg of isophthalic acid, 2.48kg of ethylene glycol, 4.16kg of neopentyl glycol and 4.72kg of 1,6-hexanediol into the container for esterification at 200-230°C for 6 hours. After a predetermined amount of water was distilled off, 2.92 kg of adipic acid was added, followed by esterification for another 6 hours. After distilling the specified amount of water, gradually reduce the pressure to 1.21×10 2 to 1×10 3 Pa, esterification reaction was carried out at this pressure and temperature range of 230-250° C. for 5 hours to obtain a polyester polyol having a number average molecular weight of 5,000, a hydroxyl value of 23 mgKOH / g and an acid value of 0.5 mgKOH / g. In addition, 0.75kg of isophorone diisocyanate was added dropwise to the above product (based on the total amount of polyester polyol, the NCO / OH molar ratio was 0.7), and then reacted at 150°C for about 2 hours to generate a number average Polyester polyurethane polyol having a molecular weight of 13,000,...

Embodiment 1-4

[0047] (Examples 1-4, and Comparative Examples 1 and 2)

[0048] Partly acid-modified polyol solutions A-E, polyisocyanate shown below, silane coupling agent and ethyl acetate were mixed according to the ratio (mass ratio) shown in Table 2, to obtain the non-volatile matter containing 25% by mass binder solution. These adhesive solutions were respectively used to produce laminates according to the following methods, and then each of the produced laminates was subjected to a lamination strength test, a hot water resistance test and an acid resistance test as described below. The results are shown in Table 3.

[0049] Polyisocyanate: CAT-RT86 (the trade name of the adduct mixture of xylylene diisocyanate and trimethylol propane and the adduct mixture of isophorone diisocyanate and trimethylol propane, a product of Japan ToyoMorton K.K. .)

[0051] γ-glyceryloxypropyltrimethoxysilane (product of Shin-Etsu Chemical Co., Ltd., Japan) (preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com