Prepn process of spinel type nanometer composite ferrite material

A nano-composite material and spinel-type technology, which is applied in the field of preparation of spinel-type ferrite nano-composite materials, can solve the problems of difficult preparation of nano-composite materials with high ferrite content, time-consuming gelation, high energy consumption, etc. problems, to achieve the effect of easy control of the process, cheap raw materials, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

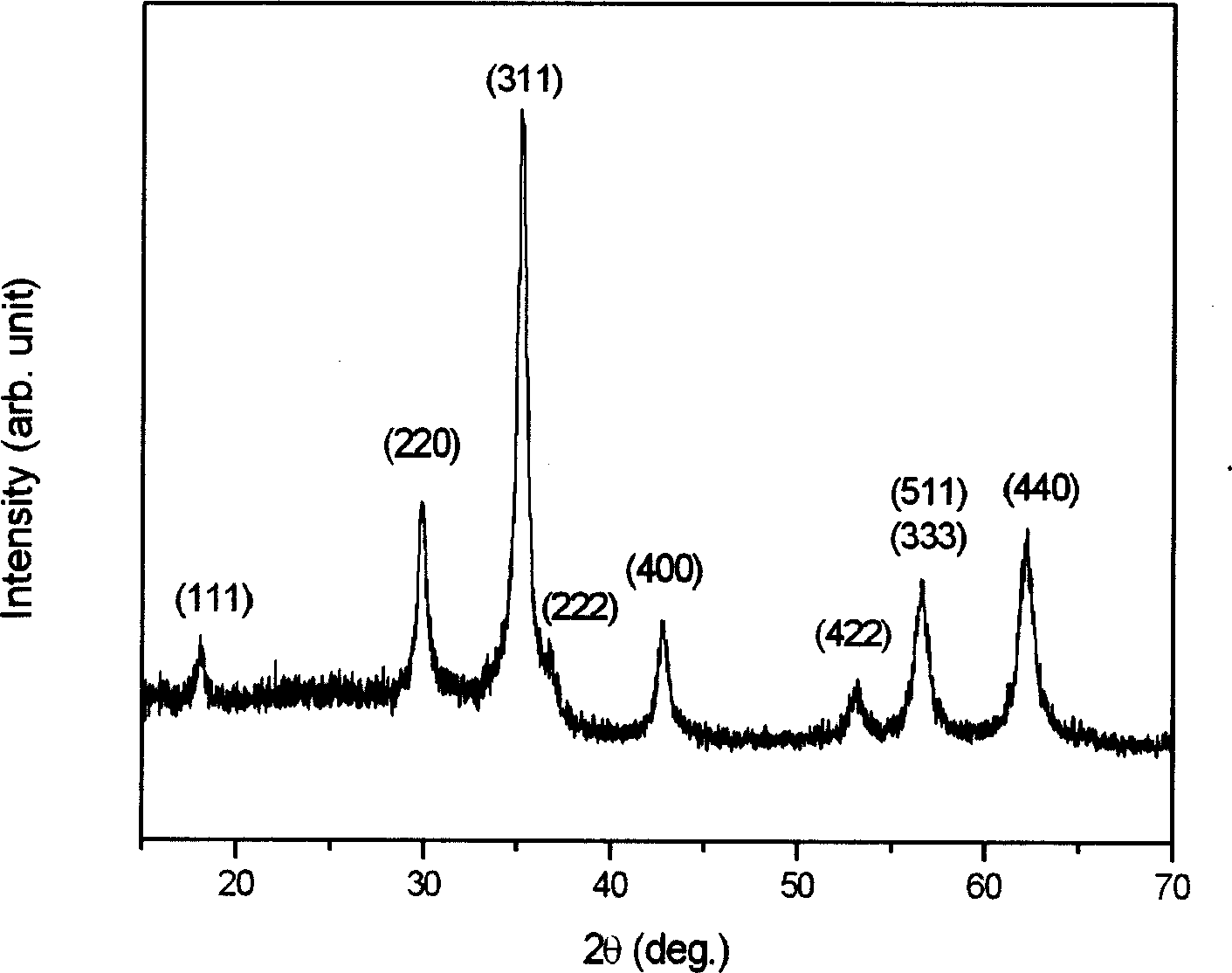

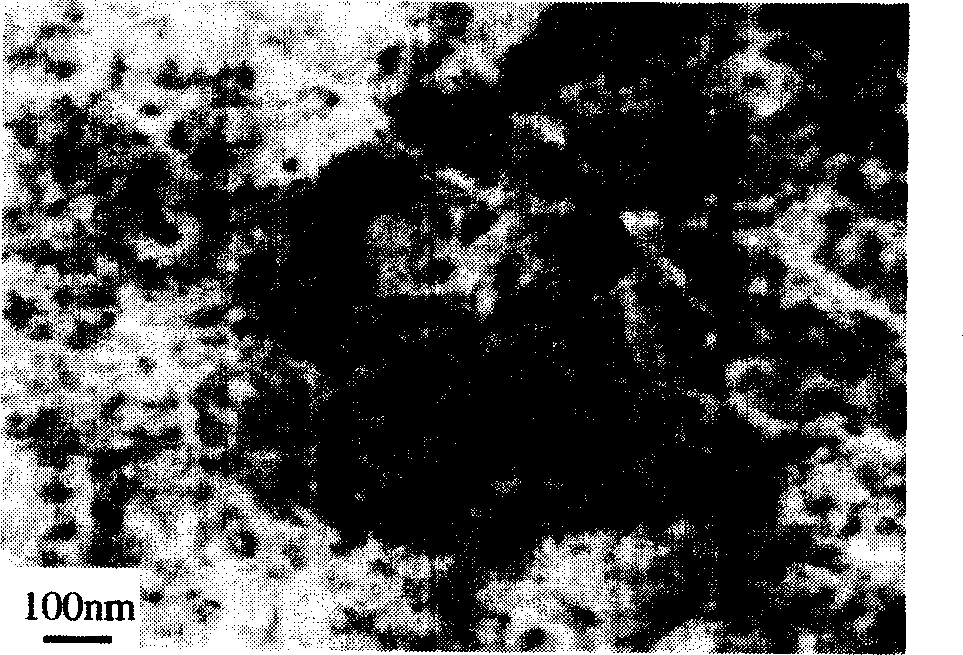

[0011] Preparation of SiO 2 10% by weight (Mn 0.3 Zn 0.7 )Fe 2 o 4 / SiO 2 Nanocomposites, TEOS / EtOH / H 2 The ratio of O was adjusted at 1:2:5, acetic acid was added to adjust the pH value of the solution to about 2, and the precursor solution was kept at 50°C for 2 hours, and TEOS was hydrolyzed to obtain a transparent and viscous sol I; the Fe(NO 3 ) 3 , Mn(NO 3 ) 2 , Zn(NO 3 ) 2 and citric acid were dissolved in deionized water to form solution II, and the molar ratio of citric acid / various metal ions was 2:3. Mix Sol I and Solution II, control the concentration of citric acid in the final solution to 1.5mol / l, add a small amount of ammonia water, adjust the pH value to 5, evaporate the solution at 70°C to obtain a transparent sol, and then dry it at 110°C for 12 hours Gel, the dry gel is ignited in the air to obtain a reddish-brown bulky powder (Mn 0.3 Zn 0.7 )Fe 2 o 4 / SiO 2 nanocomposites.

Embodiment 2

[0013] Preparation of SiO 2 20% by weight (Ni 0.5 Zn 0.5 )Fe 2 o 4 / SiO 2 Nanocomposites, TEOS / EtOH / H 2 The ratio of O was adjusted at 2:3:7, acetic acid was added to adjust the pH value of the solution to about 3, and the precursor solution was kept at 60°C for 3 hours, and TEOS was hydrolyzed to obtain a transparent and viscous sol I; Fe(NO 3 ) 3 , Ni(NO 3 ) 2 , Zn(NO 3 ) 2 and citric acid were dissolved in deionized water to form solution II, and the molar ratio of citric acid / various metal ions was 1:3. Mix sol I and solution II, control the concentration of citric acid in the final solution to 2mol / l, add a small amount of ammonia water, adjust the pH value to 8, evaporate the solution at 90°C to obtain a transparent sol, and then dry it at 150°C for 12 hours to obtain dry coagulation Glue, the xerogel is ignited in the air to obtain a reddish-brown bulky powder (Ni 0.5 Zn 0.5 )Fe 2 o 4 / SiO 2 nanocomposites.

Embodiment 3

[0015] Preparation of SiO 2 60% by weight ZnFe 2 o 4 / SiO 2 Nanocomposites, TEOS / EtOH / H 2 The ratio of O was adjusted at 3:2:9, acetic acid was added to adjust the pH value of the solution to about 3, and the precursor solution was maintained at 70°C for 4 hours, and TEOS was hydrolyzed to obtain a transparent and viscous sol I; Fe(NO 3 ) 3 , Zn(NO 3 ) 2 and citric acid were dissolved in deionized water to form solution II, and the molar ratio of citric acid / various metal ions was 1:2. Mix sol I and solution II, control the concentration of citric acid in the final solution to 1.5mol / l, add a small amount of ammonia water, adjust the pH value to 8, evaporate the solution at 90°C to obtain a transparent sol, and then dry it at 140°C for 8 hours Gel, the dry gel is ignited in the air to obtain a reddish-brown bulky powder, which is ZnFe 2 o 4 / SiO 2 nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com