A kind of continuous glass fiber reinforced thermoplastic composite material and preparation method thereof

A technology for reinforcing thermoplastic and continuous glass fibers, applied in the field of composite materials, can solve the problems of dispersion, impregnation difficulties, fiber deformation, and poor designability of layup structures, so as to reduce the risk of thermal degradation and reduce the process of heating and compounding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

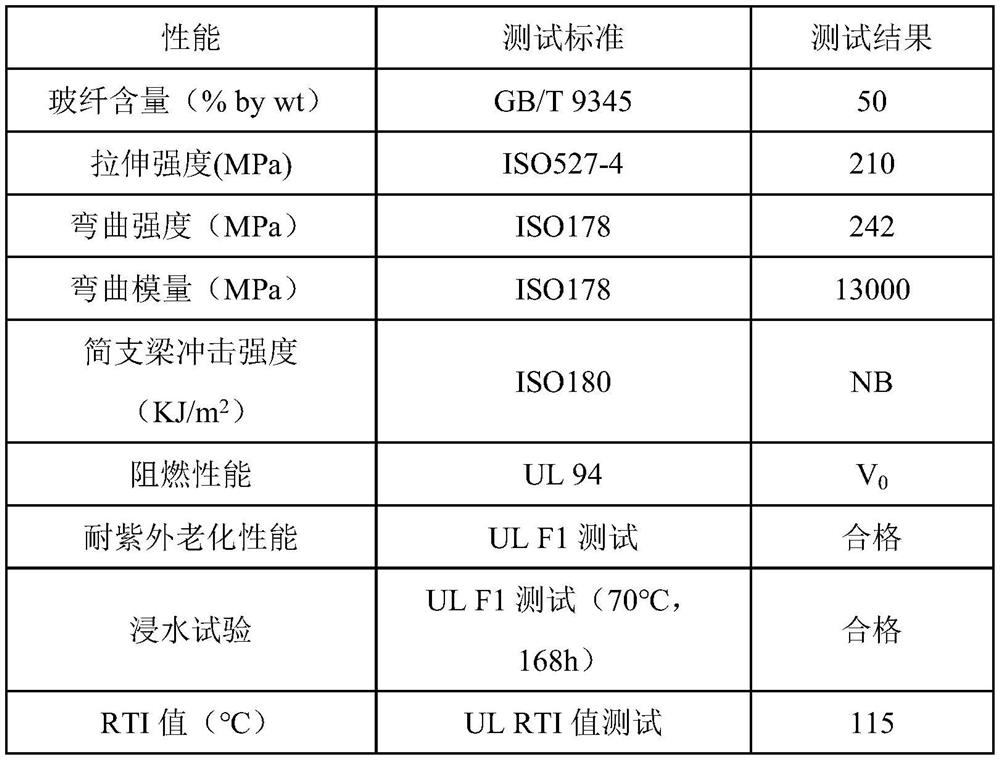

Embodiment 1

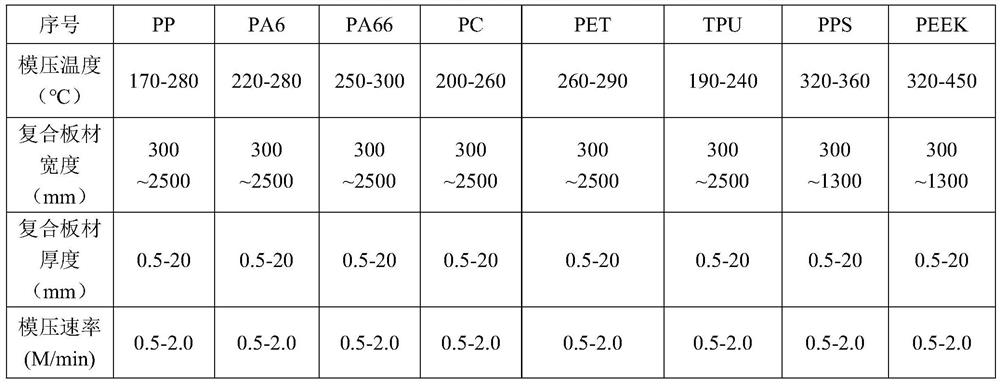

[0073] This embodiment provides a method for preparing a continuous glass fiber reinforced thermoplastic resin-based composite material, the steps are as follows:

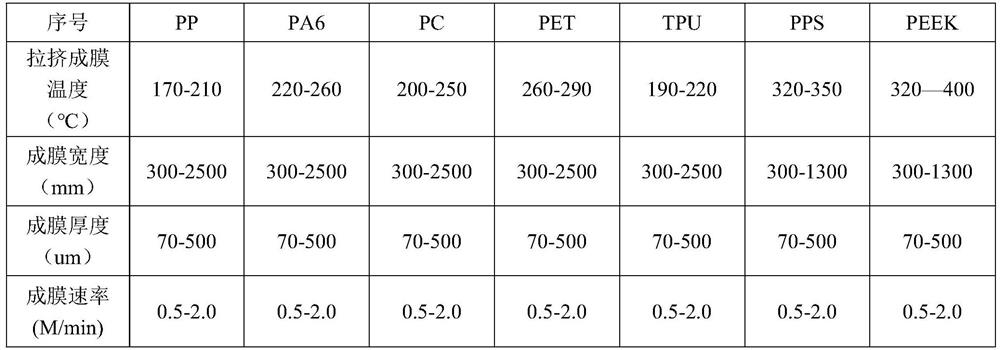

[0074] (1) 70 kg of PP resin, 10 kg of glass fiber compatibilizer (PP grafted maleic anhydride), 16 kg (decabromodiphenylethane), 4 kg of antimony trioxide, 2 kg of carbon black-containing color Mother, 0.3 kg of light stabilizer (benzophenone ultraviolet absorber), 0.3 kg of heat stabilizer are mixed evenly through the batching pot; then sheared and plasticized by a twin-screw extruder, and pultruded into a thickness of 70um, a width of 1300mm, and a length of 12 rolls of fixed-length PP resin film;

[0075] The continuous glass fiber yarn is treated with surface sizing agent emulsion, and then dehydrated by hot air baking for 12 hours; wherein, the surface sizing agent emulsion is made of aminosilane coupling agent, PE wax floating liquid, maleic anhydride grafted polypropylene emulsion, deionized An emulsion pr...

Embodiment 2

[0084] This embodiment provides a method for preparing a continuous glass fiber reinforced thermoplastic resin-based composite material, the steps are as follows:

[0085] (1) 120 kg of polyamide 6 resin, 3 kg of color masterbatch (carbon black), 0.5 kg of polyamide flow modifier, 0.5 kg of light stabilizer (hindered amine light stabilizer), 1.0 kg of heat stabilizer (sulfur Ester heat stabilizer) is uniformly mixed in a batching pot; then sheared and plasticized by a twin-screw extruder, and cast and pultruded into 30 rolls of PA6 film with a thickness of 70um, a width of 1300mm, and a fixed length;

[0086] The continuous glass fiber yarn is treated with surface sizing agent emulsion, and then dehydrated by hot air drying for 12 hours; wherein, the surface sizing agent emulsion is made of acid anhydride coupling agent, water-soluble PEG600, epoxy emulsion and polyurethane intermixing emulsion, deionized water and a small amount of acid to prepare the emulsion by stirring. Th...

Embodiment 3

[0096] This embodiment provides a method for preparing a continuous glass fiber reinforced thermoplastic resin-based composite material, the steps are as follows:

[0097] (1) 80 kg of PET resin, 30 kg of flame retardant (magnesium hydroxide), 1.5 kg of color masterbatch (carbon black), 0.5 kg of PET resin flow modifier, 1.2 kg of heat stabilizer (phenolic heat stabilizer) Mix evenly through a batching pot; then shear, plasticize and granulate through a twin-screw extruder, and then quench and grind into 30-50 mesh PET resin powder through liquid nitrogen;

[0098] The continuous glass fiber yarn is treated with surface sizing agent emulsion, and then subjected to hot air baking and dehydration treatment for 12 hours; wherein, the surface sizing agent emulsion is composed of KH570 coupling agent, fatty acid ester lubricant, polyurethane emulsion and epoxy emulsion composition, deionized An emulsion prepared by stirring water and a small amount of formic acid. The active ingred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com