A nitrogen doping method for preparing low COP defect silicon single crystal

A technology of silicon single crystal and nitrogen doping, which is applied in the directions of single crystal growth, single crystal growth, diffusion/doping, etc., can solve the problems of weak silicon single crystal COP defect suppression and poor nitrogen doping effect, etc., to achieve Low heating power, reduced production cost, and high dissociation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

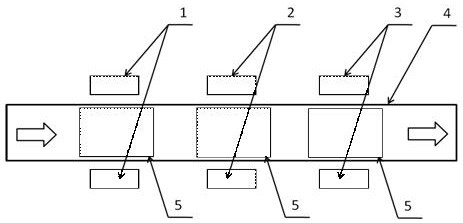

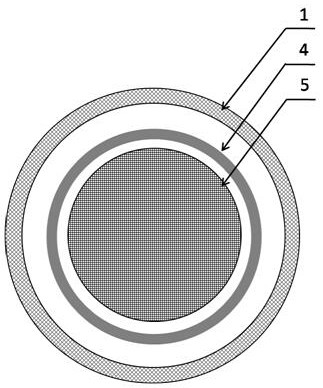

[0031] Embodiment 1: The nitrogen doping method for preparing low COP defect silicon single crystal has the following steps:

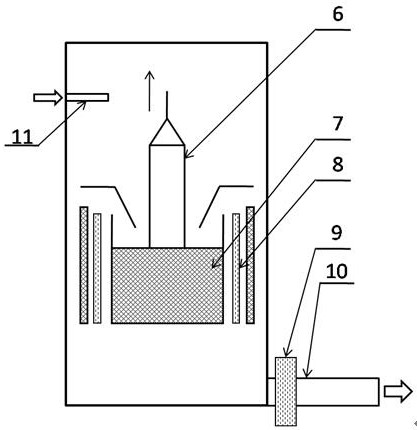

[0032] (1) if image 3 As shown, an ammonia gas high-temperature ionization device 11 is added in the middle of the Czochralski method silicon single crystal furnace chamber; during the growth process of the Czochralski method silicon single crystal 6, high-purity ammonia gas is passed into the ammonia gas high-temperature dissociation device to generate N( g), the ammonia flow rate is 0.03SLM. In this embodiment, the temperatures of the inlet area, middle area, and outlet area of the heater are set as follows: 1250°C, 1150°C, and 1050°C.

[0033] (2) N (g) dissolves in the silicon melt 7 and diffuses to the solid-liquid interface of the single crystal growth, and then enters the interior of the silicon single crystal as the growth process progresses to realize the nitrogen doping process and inhibit the silicon single crystal Crystalline COP defec...

Embodiment 2

[0036] Embodiment 2: The nitrogen doping method for preparing low COP defect silicon single crystal has the following steps:

[0037] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that an ammonia gas high-temperature ionization device 11 is added at the lower part of the chamber of the Czochralski silicon single crystal furnace, that is, near the position of the graphite heater; this embodiment sets the heater inlet The temperature of the area, the middle area, and the outlet area are as follows: 850°C, 750°C, and 650°C.

[0038] Since the ammonia gas high-temperature ionization device 11 is placed near the graphite heater 8, the high-temperature ionization process of ammonia gas can be completed by the heating effect of the graphite heater 8. Therefore, compared with embodiment 1, this embodiment can significantly reduce the heating rate. The heating power of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com