Three-position and five-way angular valve and automatic watersupply treating system controlled it

A treatment system, three-position five-way technology, applied in water/sewage treatment, water treatment parameter control, water/sludge/sewage treatment, etc. Cost and other issues, to achieve the effect of reducing radial and axial dimensions, easy to ensure the accuracy of the outer diameter, and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

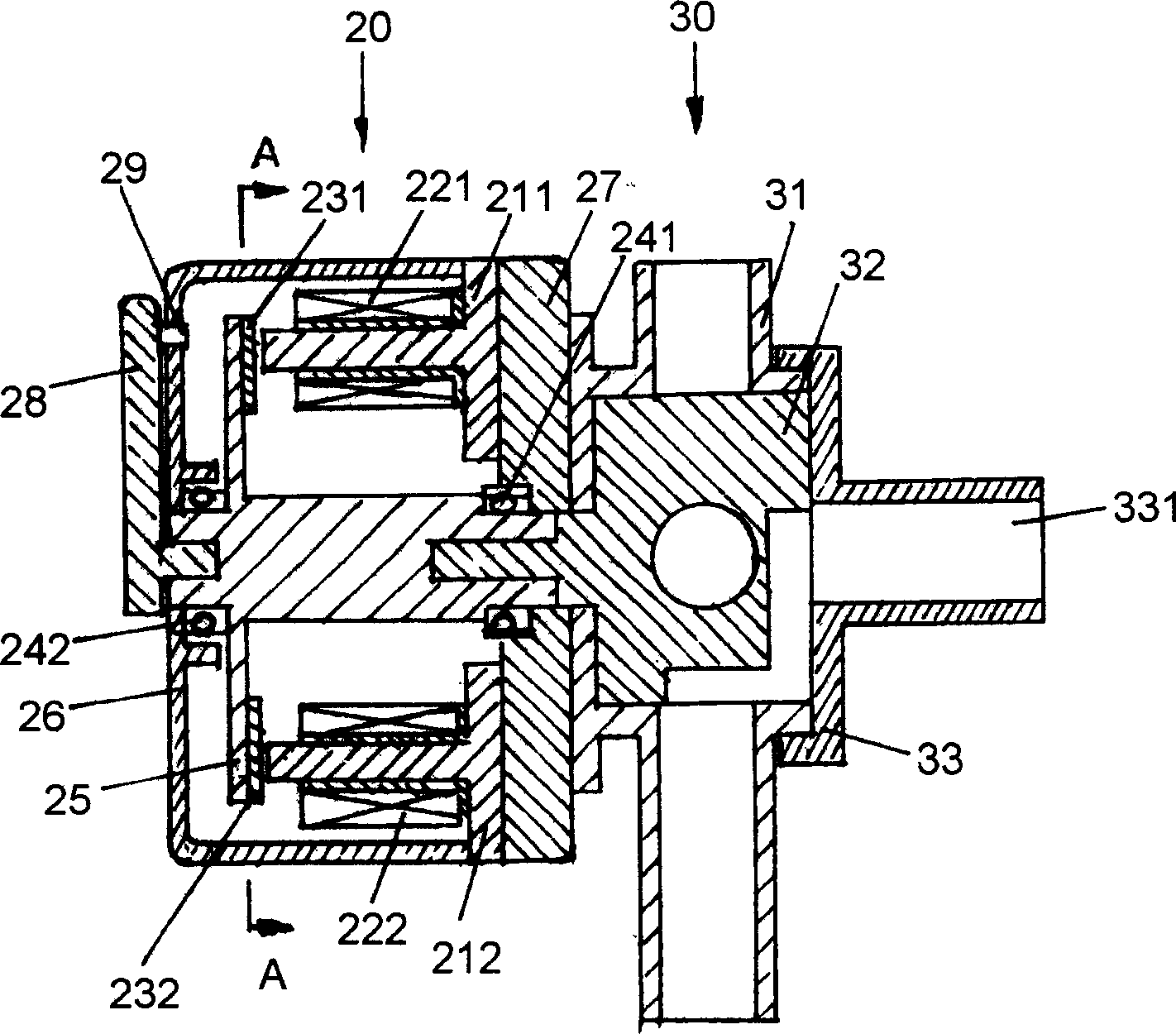

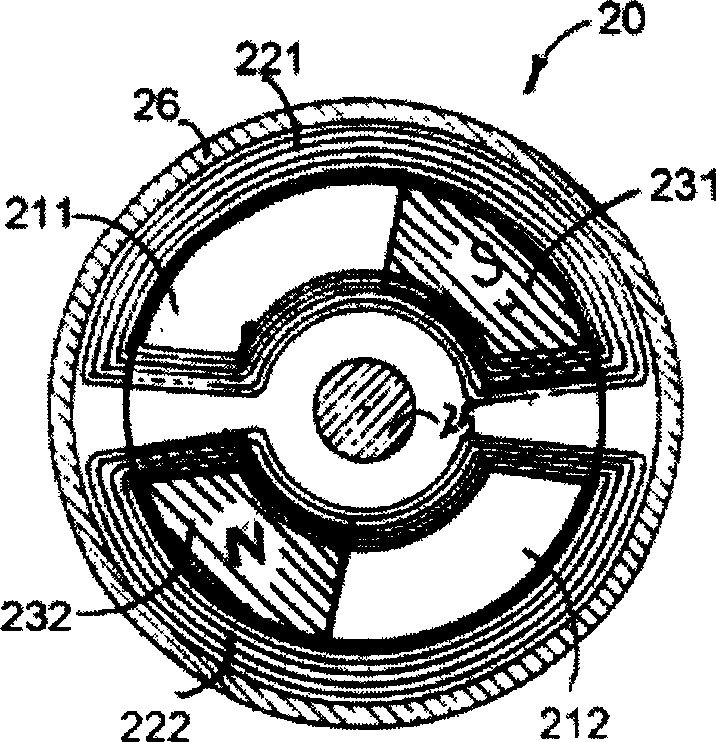

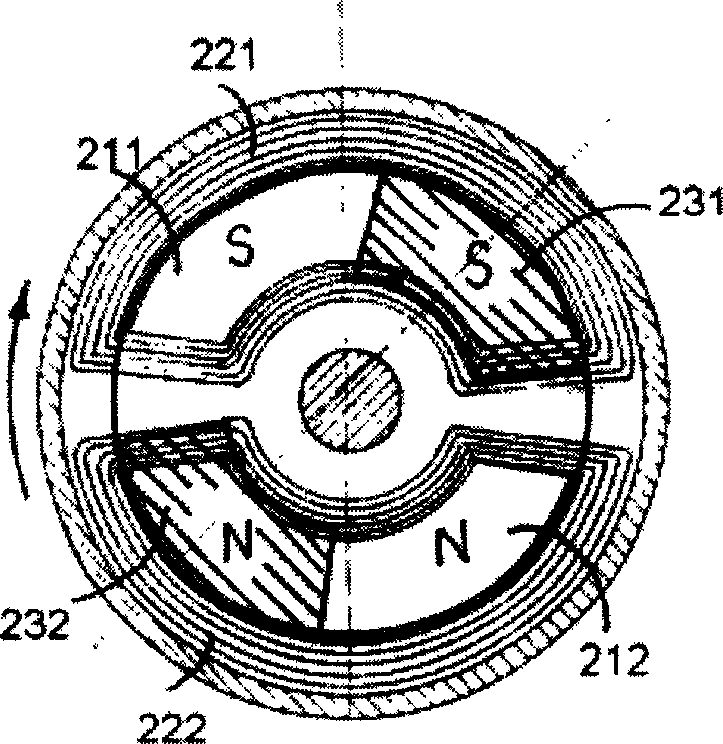

[0047] Below, the specific structure and working process of the three-position five-way rotary valve and the fully automatic tap water treatment system controlled by the valve will be described in detail in conjunction with the accompanying drawings.

[0048] First, combine figure 1 , image 3 , Figure 5 , Figure 6 , to illustrate the specific structure of the three-position five-way rotary valve.

[0049] The three-position five-way rotary valve 1 is composed of a controller 10, an actuator 20 and a five-way rotary valve 30. The controller 10 sends a command signal to drive the actuator 20, and the actuator 20 drives the five-way rotary valve 30 to complete the angular displacement.

[0050] The controller 10 is composed of a microcomputer, including a central processing unit (CPU) that performs calculation processing according to a control program, a read-only memory (ROM) that stores the control program, a random access memory (RAM), a clock, and an input / output interf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com