Method of preparing ethylene glycol

A technology of ethylene glycol and ethylene oxide, which is applied in the field of ethylene glycol production in reactive distillation towers, can solve the problems of long process flow, large equipment investment, high water ratio of non-catalytic hydration reaction, etc., and achieve simplified process flow , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

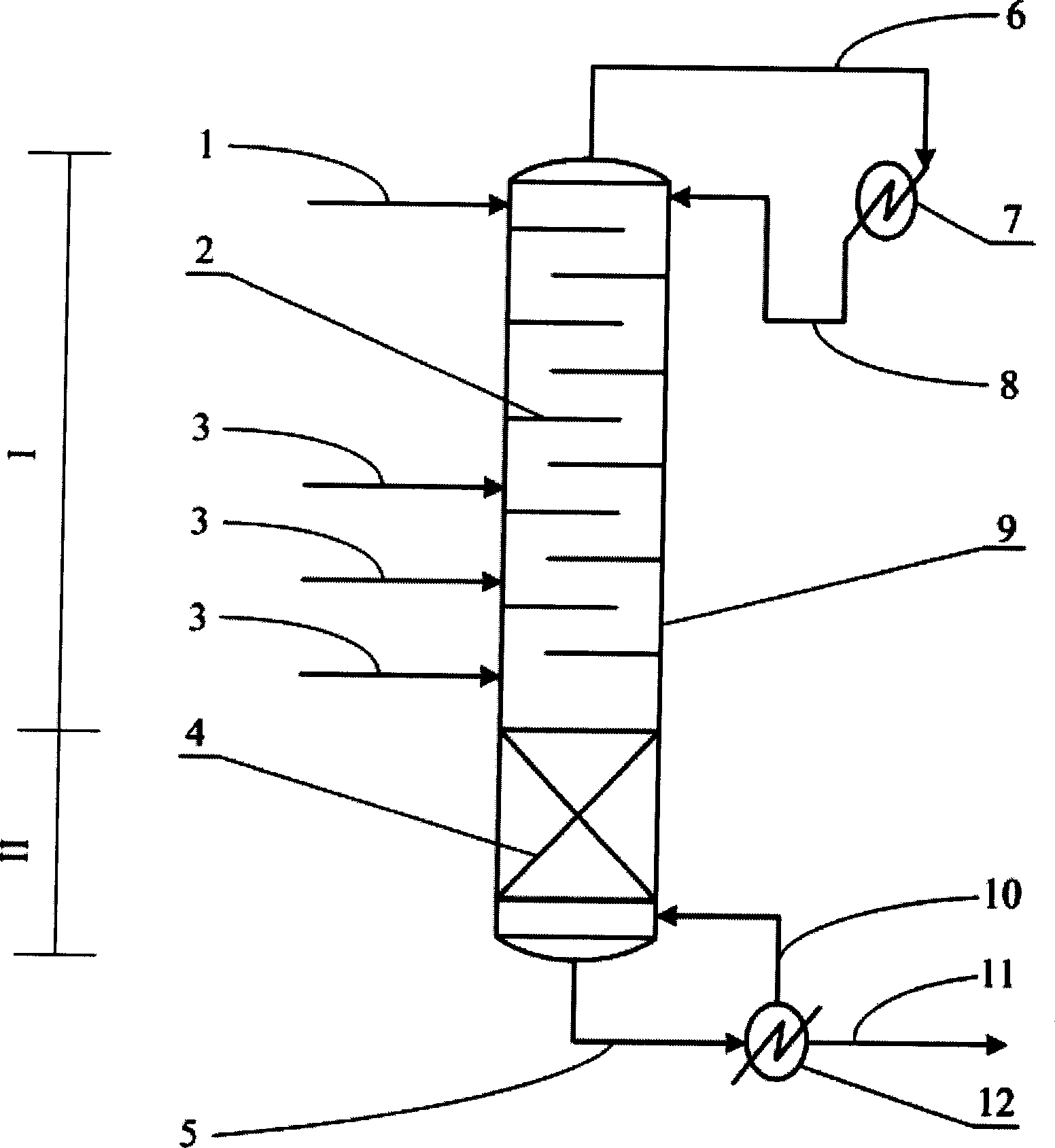

[0024]In the reactive distillation column with an inner diameter of 24 mm, 10 trays in the reactive distillation section and 6 trays in the stripping section are set. Water is fed from the top of the tower with a flow rate of 21.6 grams / hour, and ethylene oxide has only one feed port, and it is fed from the eleventh section of the tray (from top to bottom) with a flow rate of 17.6 grams / hour. The feed is based on the molar ratio, and the water ratio is 3:1. Ethylene oxide and water react in the reaction rectification section, the reaction temperature is 184°C, the operating pressure of the tower is 1.1MPa in terms of absolute pressure, and the product stream generated by the reaction (including monoethylene glycol, diethylene glycol and a small amount Polyethylene glycol) enters the next layer of tray through the liquid phase and flows down, enters the stripping section, and the product is concentrated by the stripping section, and the product is discharged from the bottom of ...

Embodiment 2

[0028] In the reactive distillation column with an inner diameter of 24 mm, 15 trays in the reactive distillation section and 6 trays in the stripping section are set. Water feeds from tower top with the flow rate of 18.0 grams / hour, and ethylene oxide has three feeding ports, is divided into three shares of same flow with total flow rate 17.6 grams / hour from the 9th, 12th, 15th column plate (by upper From the bottom to the bottom) places are fed respectively, and the feed is in molar ratio, and the water ratio is 2.5:1. Ethylene oxide and water react in the reactive distillation section, the reaction temperature is 184°C, the operating pressure of the control tower is 1.1MPa in terms of absolute pressure, and the product stream generated by the reaction (including monoethylene glycol, diethylene glycol and A small amount of polyethylene glycol) flows down through the liquid phase into the next layer of trays, enters the stripping section, and the product is concentrated by th...

Embodiment 3

[0032] According to the kinetic data obtained in the above-mentioned Examples 1 and 2, the internal diameter of the reactive distillation column is 4400 mm, the reactive distillation section has 20 trays, and the stripping section has 8 trays to simulate the production scale. Water is fed from the top of the tower at a flow rate of 390.3 kilomoles / hour, and ethylene oxide has only one feed port, which is fed from the twentieth section plate (from top to bottom) at a flow rate of 139.4 kilomoles / hour. Material, feed is calculated in molar ratio, and water ratio is 2.8: 1. The operating pressure of the control tower is 1.2MPa in terms of absolute pressure, the temperature of the tower bottom is 207.7°C, and the typical temperature of the reaction distillation section is 188°C. The material discharged from the top of the tower is condensed into a single liquid phase with cooling water, all of which flow back into the tower, and only the material discharged from the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com