Method for preparing magnetic compound material of ferric oxide cladded carbon nanotube

A technology of magnetic composite material and ferric oxide, applied in the direction of metal material coating process, etc., can solve the problems of complex method, unexplored magnetic properties of composite materials, long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

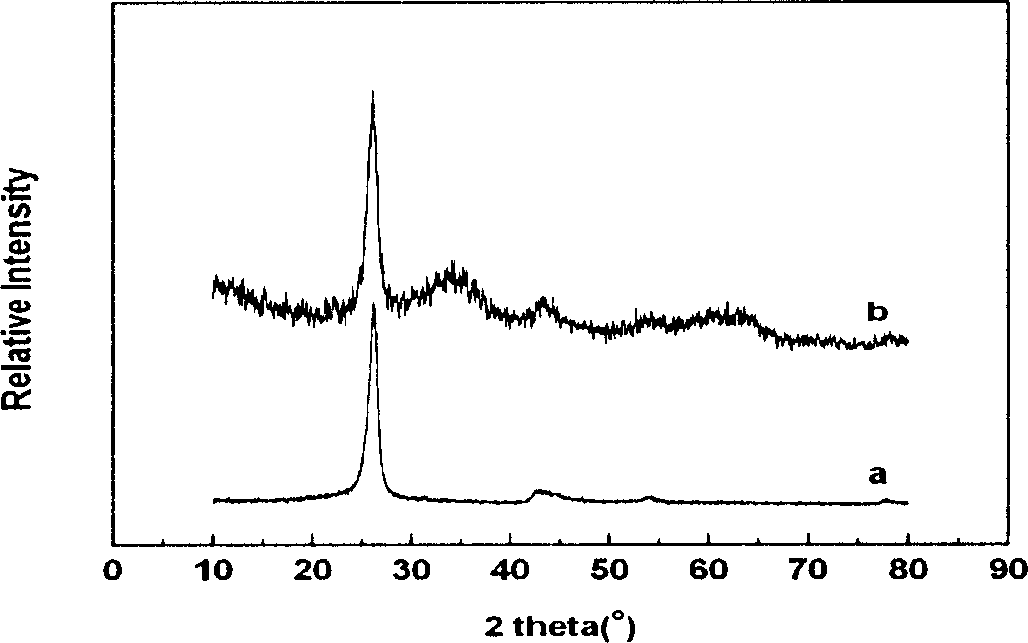

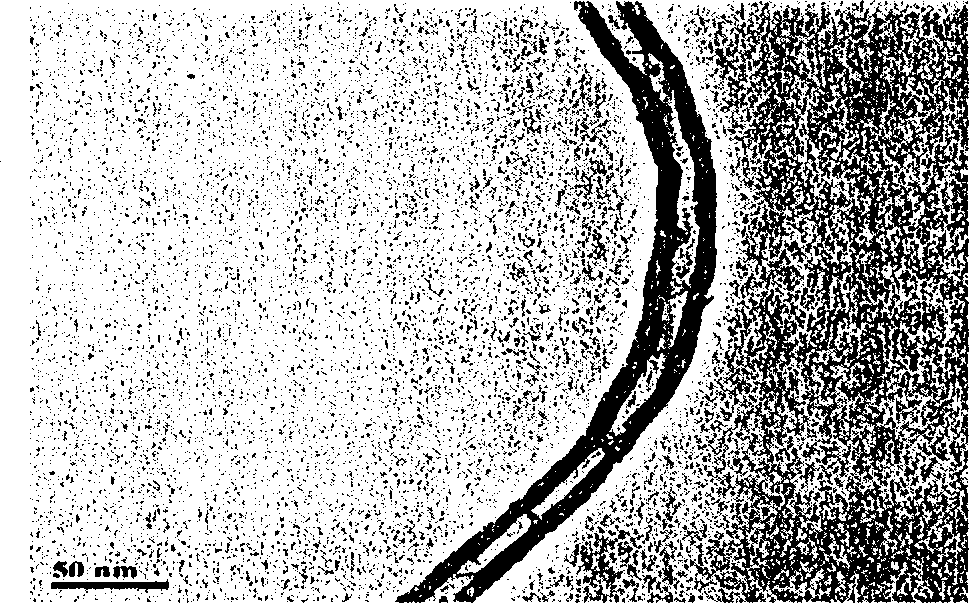

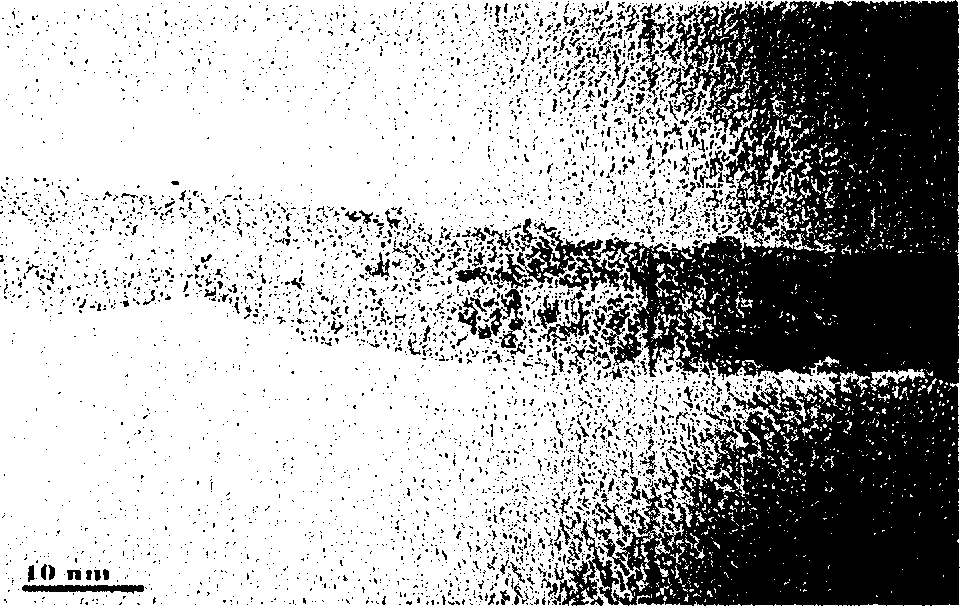

[0025] At room temperature, 27gFe(NO 3 ) 3 9H 2 O and 200ml of concentrated nitric acid were stirred and mixed at a speed of 600 rpm, then 5g of carbon nanotubes were added, ultrasonically dispersed, and refluxed in an oil bath at 120°C for 4.5 hours, and the temperature of the refluxed mixture was lowered to 20°C. The wt% ammonia water is titrated until the pH is 10, the titrated solution is filtered with a 0.65 μm filter membrane, and the filtrate is washed with deionized water several times, dried in an oven at 80°C for 12 hours, and the filtrate is dried Finally, the carbon nanotubes coated with iron hydroxide were obtained, put them into a quartz boat, put them into a tube-type atmosphere furnace, feed nitrogen gas, the gas flow rate was 1 liter / min, and the heating rate was 5°C / min, from room temperature to 250 ℃, after 1 hour of heat preservation, at 10℃min -1 The temperature was raised to 650° C., calcined at 650° C. for 2 hours, and naturally cooled to room tempera...

Embodiment 2

[0033] At room temperature, 21gFeCl 3 Stir and mix with 100ml of concentrated nitric acid at a speed of 400 rpm, then add 2.5g of carbon nanotubes, ultrasonically disperse, and prepare according to the method described in Example 1 below. X-ray diffraction and transmission electron microscopy analysis show that the carbon nanotubes are coated with ferric oxide, and the magnetic test shows that the magnetic properties of the material after coating are obviously improved.

Embodiment 3

[0035] At room temperature, 27gFe(NO 3 ) 3 9H 2O and 200ml of concentrated nitric acid were stirred and mixed at 800 rpm, then 5g of carbon nanotubes were added, ultrasonically dispersed, and refluxed in an oil bath at 120°C for 4.5 hours. When the temperature of the refluxed mixture dropped to room temperature, use 2.0 The sodium hydroxide of wt% is titrated, and is prepared by the method described in Example 1 below. X-ray diffraction and transmission electron microscopy analysis show that the carbon nanotubes are coated with ferric oxide, and the magnetic test shows that the magnetic properties of the material after coating are obviously improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com