Blended fiber of sodium alginate/water soluble chitin, preparation method and application thereof

A technology of water-soluble chitin and sodium alginate, which is applied in the field of polymer chemical materials, can solve the problems of unsatisfactory elasticity and strength of alginate fiber, and achieve the effects of good mechanical properties, abundant raw material sources, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

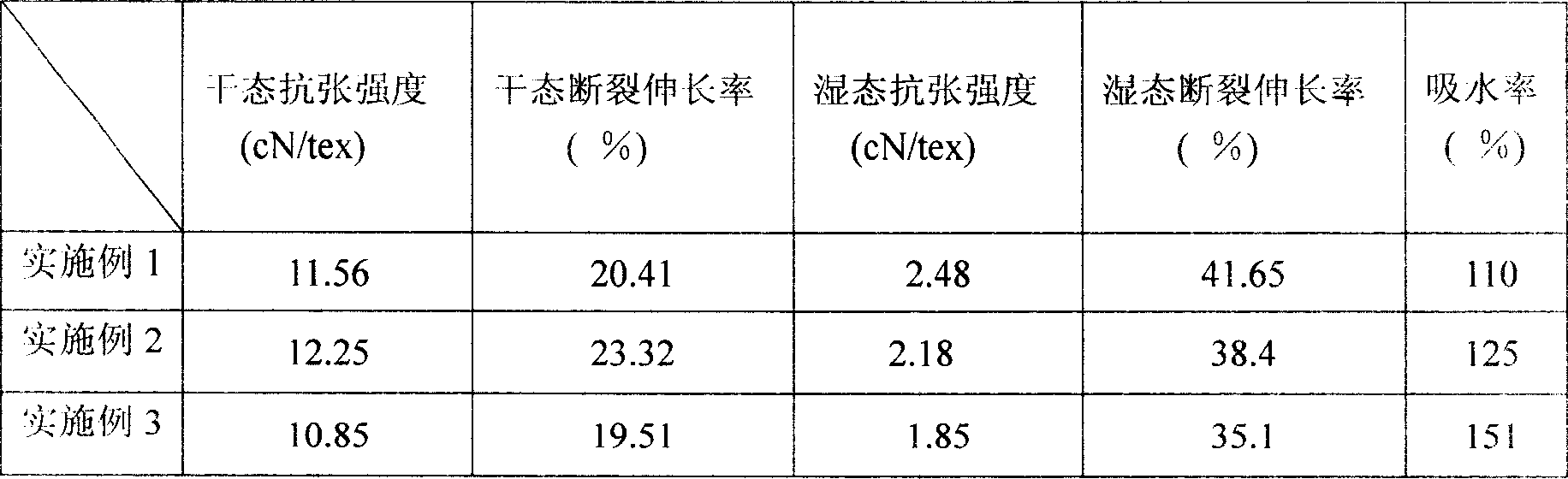

Embodiment 1

[0011] Embodiment 1: get 45g sodium alginate and be dissolved in 855ml distilled water and obtain the sodium alginate solution of 5% (mass percentage); 40g chitosan is dissolved in 600ml40% (volume percentage) methyl alcohol, 3% (volume percentage) in the mixed aqueous solution of acetic acid , add 15g of acetic anhydride, stir and react at room temperature for 6 hours, add enough acetone, the precipitate is filtered, desalinated, and dried to obtain water-soluble chitin. 5 g of water-soluble chitin was dissolved in distilled water to obtain a 5% (mass percent) water-soluble chitin solution. The above two solutions were fully mixed, filtered, and after degassing under reduced pressure, at room temperature, the composition was 5% (mass percentage) CaCl 2 Sodium alginate / water-soluble chitin fibers were prepared by solution spinning in the coagulation liquid of the mixed liquid of the aqueous solution and 30% (volume percent) absolute ethanol, and the fiber elongation rate was 3...

Embodiment 2

[0012] Embodiment 2: get 35g sodium alginate and be dissolved in 840ml distilled water and obtain 4% (mass percentage) sodium alginate solution; 40g chitosan is dissolved in 600ml50% (volume percentage) methanol, 4% (volume percentage) in the mixed aqueous solution of acetic acid , add 17g of acetic anhydride, stir and react at room temperature for 5 hours, add enough acetone, the precipitate is filtered, desalinated, and dried to obtain water-soluble chitin. 15 g of water-soluble chitin was dissolved in distilled water to obtain a 4% (mass percentage) water-soluble chitin solution. The above two solutions were fully mixed, filtered, and after degassing under reduced pressure, at room temperature, the composition was 7% (mass percentage) CaCl 2 Sodium alginate / water-soluble chitin fibers were prepared by solution spinning in the coagulation liquid of the mixed liquid of the aqueous solution and 40% (volume percent) absolute ethanol, and the fiber elongation rate was 20%.

Embodiment 3

[0013] Embodiment 3: get 25g sodium alginate and be dissolved in 808ml distilled water and obtain 3% (mass percentage) sodium alginate solution; 40g chitosan is dissolved in 600ml60% (volume percentage) methanol, 5% (volume percentage) in the mixed aqueous solution of acetic acid , add 18g of acetic anhydride, stir and react at room temperature for 3 hours, add a sufficient amount of acetone, the precipitate is filtered, desalinated, and dried to obtain water-soluble chitin. 25 g of water-soluble chitin was dissolved in distilled water to obtain a 3% (mass percent) water-soluble chitin solution. The above two solutions were fully mixed, filtered, and after degassing under reduced pressure, at room temperature, the composition was 10% (mass percentage) CaCl 2 Sodium alginate / water-soluble chitin fibers were prepared by solution spinning in the coagulation liquid of the mixed liquid of the aqueous solution and 50% (volume percent) absolute ethanol, and the fiber elongation rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com