Test paper for testing afatoxin by nontoxic system immunochromatographic techniqul and preparing process thereof

A technology for immunochromatographic detection and aflatoxin, which is applied in measurement devices, analysis materials, and material analysis by optical means, etc., can solve the problems of health hazards, high price, and dependence on imports for production and operators, and avoid two problems. The effect of secondary pollution, easy operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

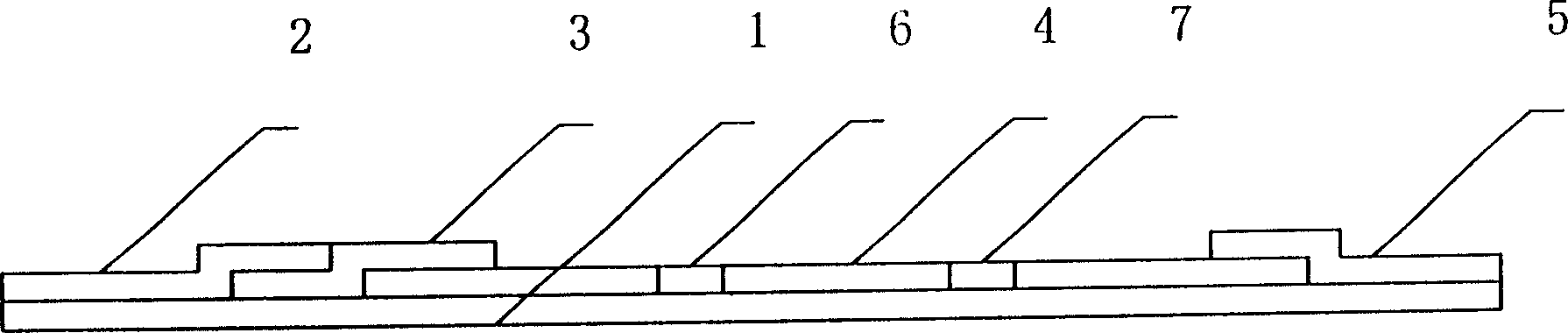

[0102] A non-toxic system immunochromatographic test paper for detecting aflatoxin, comprising a bottom plate 1, a sample pad 2, a tracer particle conjugate pad 3, a nitrocellulose membrane 4, an absorbent pad 5, a detection line 6, and a quality control line 7, Among them: on the bottom plate 1, there are sample pad 2, tracer particle conjugate pad 3, nitrocellulose membrane 4, and water-absorbing pad 5 in sequence; tracer particle conjugate pad 3 has anti-aflatoxin single labeled with tracer particle For the cloned antibody, a detection line 6 and a quality control line 7 are also provided on the nitrocellulose membrane 4. The detection line 6 is composed of aflatoxin non-toxic system linear spots that can be combined with the anti-aflatoxin monoclonal antibody. The control line 7 is composed of line-like spotting of donkey anti-mouse antibody which can be combined with anti-aflatoxin monoclonal antibody.

[0103] Detection principle: Drop the sample on the sample pad 2. If ...

Embodiment 2

[0105] A method for preparing a test paper for detecting aflatoxin by immunochromatography in a non-toxic system, comprising the following steps: processing of a sample to be tested; preparation of a nitrocellulose membrane 4 detection line 6 and a quality control line 7; tracer particle conjugate pad Preparation of 3; Assembling test strips; It is characterized in that: the preparation of nitrocellulose membrane 4 detection line 6 and quality control line 7 includes the following steps: using aflatoxin non-toxic that can be combined with anti-aflatoxin monoclonal antibody The linear spotting of the system is used as the detection line 6; the linear spotting of the donkey anti-mouse antibody that can bind to the anti-aflatoxin monoclonal antibody is used as the quality control line 7. All the other are with embodiment 1.

Embodiment 3

[0107] A method for preparing a test paper for detecting aflatoxin by immunochromatography with a non-toxic system, characterized in that the non-toxic system for preparing the detection line 6 is selected in this way: 100 μl (100 μg / ml) of anti-aflatoxin monoclonal antibody is packaged at 4 ° C Block overnight with 3% skim milk at 4°C for 2h, wash 6 times with Tris-hydrochloric acid washing solution (TBST, 50mM Tris-HCl pH7.5, 150mM NaCl, 0.1% Tween20), add 100μl of phage peptide library to each well, and store at room temperature Combine for 1 hour, then wash 10 times with TBST, add 100 μl of eluent (Gly-HCL pH2.2) to each well for elution; after neutralizing the eluent, keep a part for titer determination, and add the rest to 20ml to inoculate with logarithm The E.coli ER2738 in the early growth stage was expanded and cultured in the LB culture medium. After shaking culture at 37°C for 4.5h, it was centrifuged at 10000r / min at 4°C for 10min, and 1 / 6 volume of polyethylene gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com