Laser interference photo etching method adopting holographic optical elements and photo etching system

A holographic optical element and laser interference lithography technology, which is applied in the improvement field of laser interference lithography system, can solve the problems of large beam splitter and poor adaptability of patterns of different periods, and achieve improved signal-to-noise ratio, light weight, and reduced Effect of System Fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

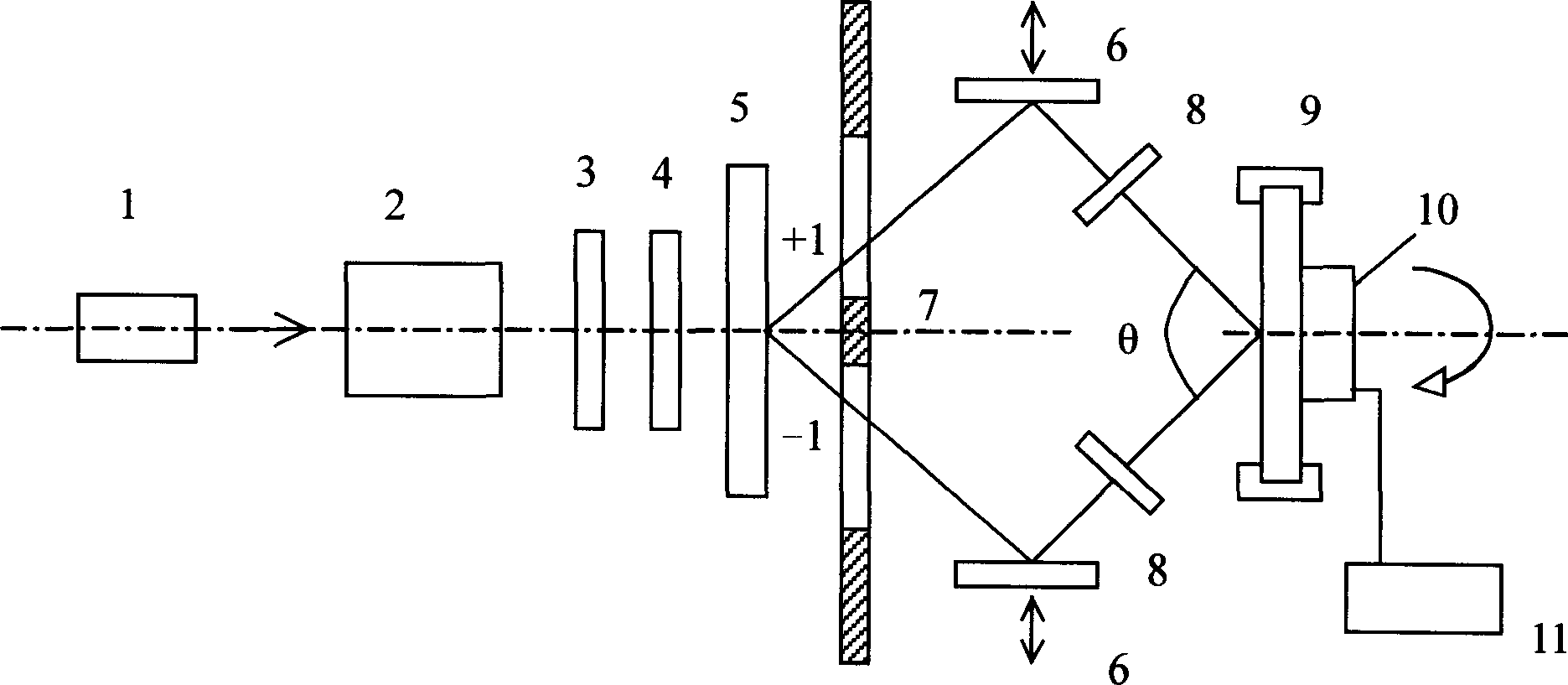

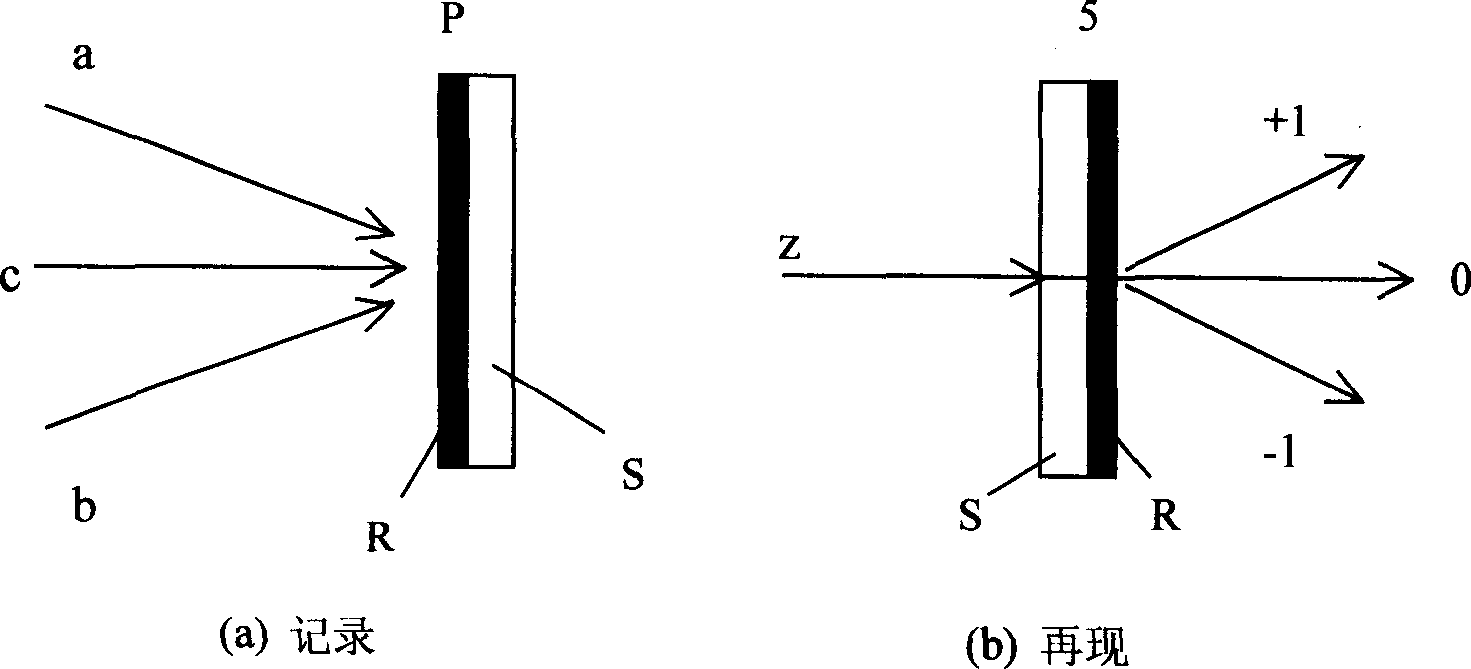

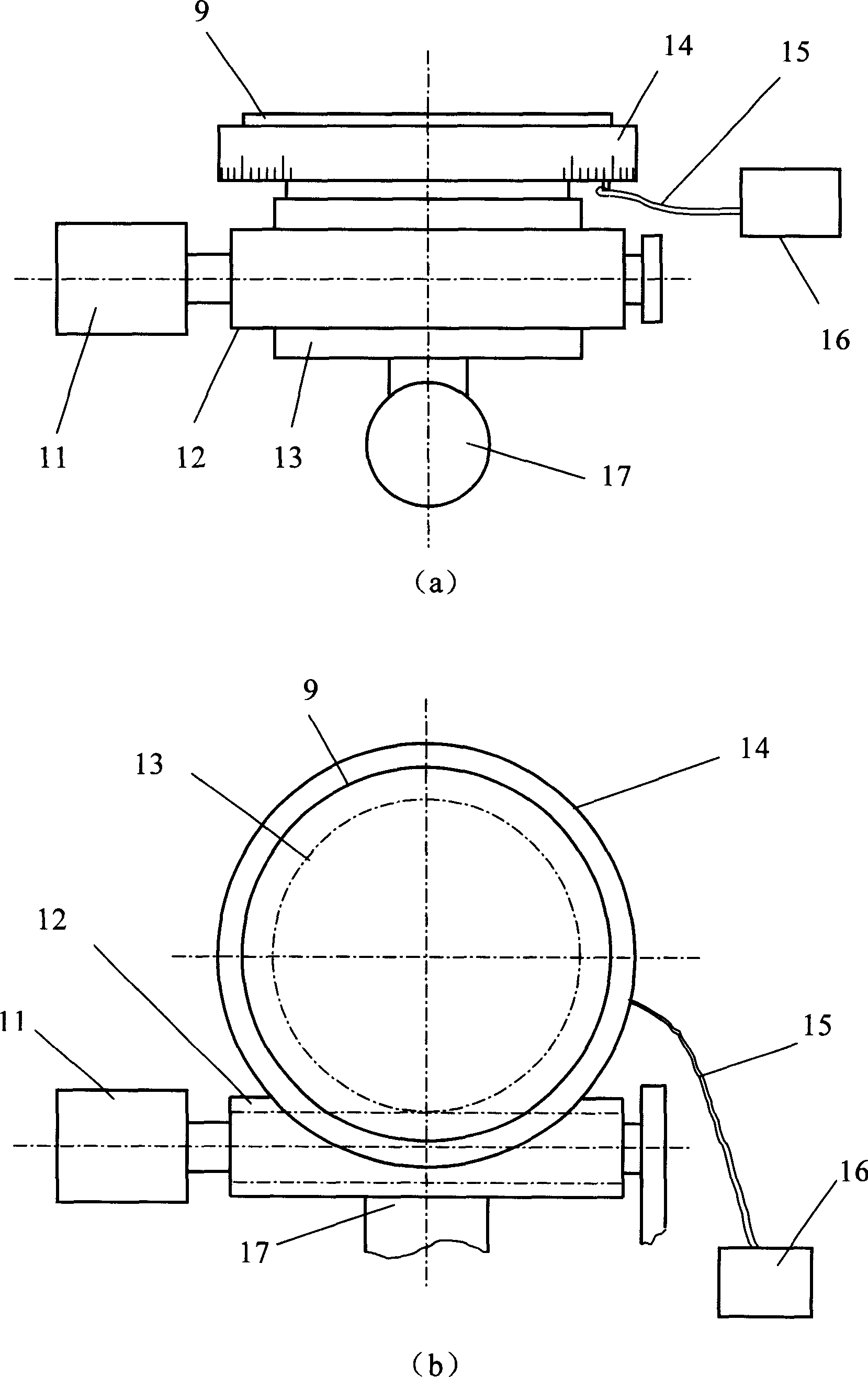

[0015] Such as figure 1 As shown, the present invention includes a laser 1, a beam expander collimator 2, a timing shutter 3, a variable density filter 4, a holographic optical element 5, a total reflection mirror 6, an adjustable diaphragm 7, an optical attenuator 8, a base Sheet and its holder 9, electric control rotation mechanism 10 and control power supply 11. The laser light emitted by the laser 1 is incident on the holographic optical element 5 after passing through the beam expander collimator 2, the timing shutter 3, and the variable density filter 4, and the beams (+1) and (- 1) Pass through the adjustable diaphragm 7, pass through the total reflection mirror 6 and the light attenuator 8, intersect at an angle θ and overlap the resist substrate 9, and expose the photoresist coated on the substrate 9 After exposure, after developing, baking and other treatments, a one-dimensional grating pattern can be obtained. After the first exposure, before processing such as de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com