Tree bast fiber yarn and its processing method

A bast fiber and processing method technology, applied in the field of textile yarn, can solve the problem of impossible to provide mulberry, and achieve the effects of excellent dyeing performance, huge economic and social benefits, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

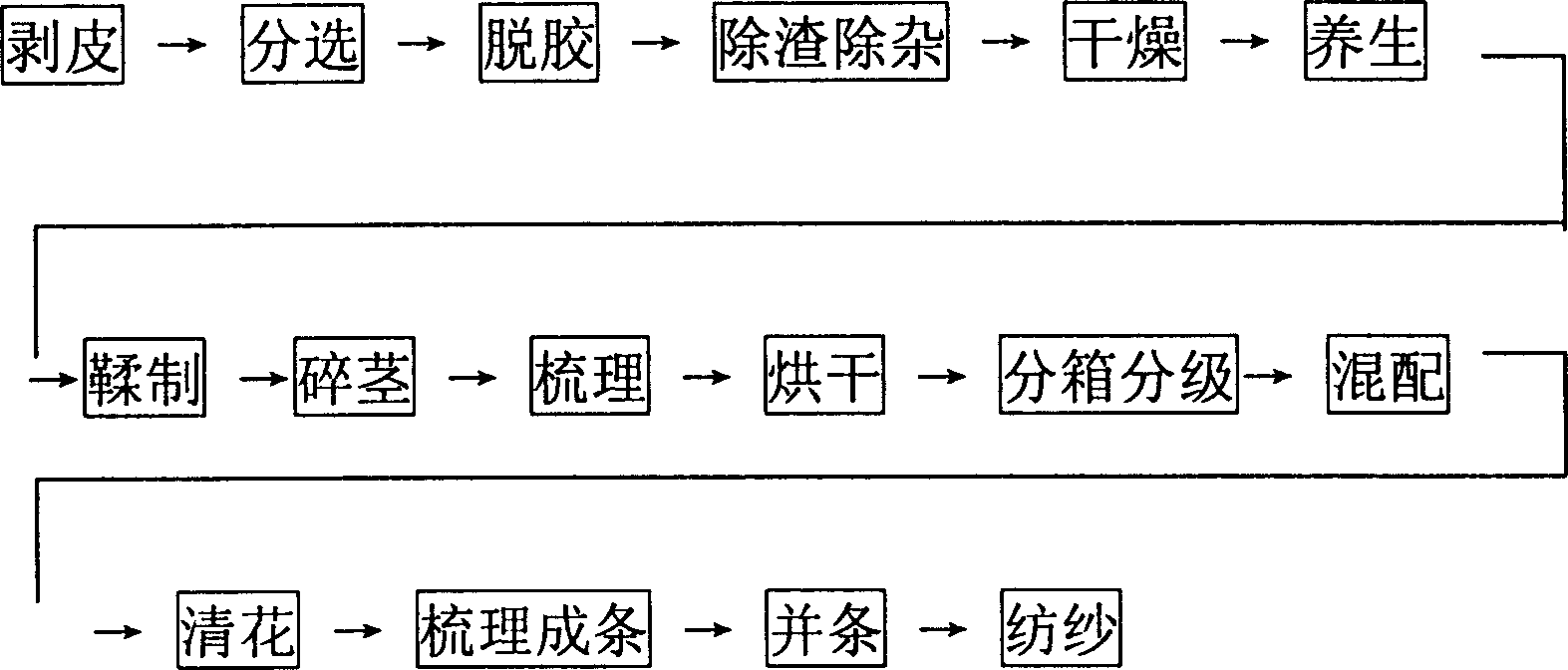

[0032] Processing of tree bast fibers

[0033] Get freshly felled trees and branches, separate the bark from the branches by hand, put the sodium hydroxide concentration into 3g / L, add washing powder with 1% by weight, and soak in a pool with a temperature of 40°C for 24 hours Finally, take it out and dry it, put it into the humidification bin, spray the emulsion evenly, and then cover it with cloth for 18 hours of health preservation; put the bast fiber after the health care treatment into the following weight percentage: 1% Remybang A, 1% Soak Pingpingjia, 1% JFC, 1% palm oil, and 1% engine oil in water at 40°C for tanning, cut the bast fiber after tanning into about 70mm, open it with a cotton opener, and put it into a carding machine Carding 3 to 5 times, collecting the combed fibers and putting them into an oven for drying, and then separating them into bast fibers of different specifications through an airflow classification box.

Embodiment 2

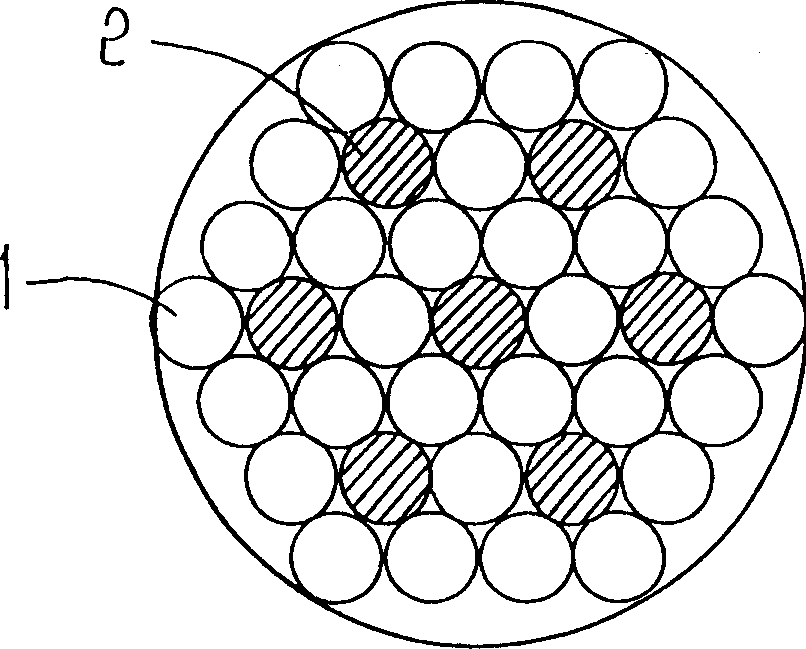

[0035] Processing of tree bast fiber yarn

[0036] Mixing: the processed 20~40mm of embodiment 1, 100% tree bast fiber of 1.0D~2.0D level, evenly spray the aqueous solution that adds 2% palm oil, and evenly mix 0.8% talcum powder, Continuously open twice with a traditional opener, and seal it in a non-ventilated place for 20 hours.

[0037] Cleaning: The mixed bast fiber is further removed by traditional cleaning process, mixed evenly, and then rolled.

[0038] Carding into strips: According to the traditional carding process, the rolled tree bast fibers are formed into strips.

[0039] Draw frame: Use traditional draw frame for 5 consecutive draw frames to make it a qualified sliver for textile equipment.

[0040] Spinning: Twisting and spinning into yarn with traditional ring spinning equipment.

Embodiment 3

[0042] Production of Tree Bast Fiber / Cotton Fiber Blended Yarn

[0043] Mixing: the tree bast fiber processed in Example 1 is uniformly mixed with 0.5% talcum powder according to 60% and 40% cotton fiber (38mm, 1.5D), and is continuously opened twice with a traditional opener , sealed in a non-ventilated place for 24 hours.

[0044] All the other processes of blowing, carding into sliver, drawing, and spinning are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com