Process for preparing N-acetyl morpholine

The technology of acetylmorpholine and morpholine is applied in the field of preparation of N-acetylmorpholine, can solve the problems of low production intensity of reactor, high production cost, low utilization rate of raw materials, etc., achieves low cost, large production capacity, improved The effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

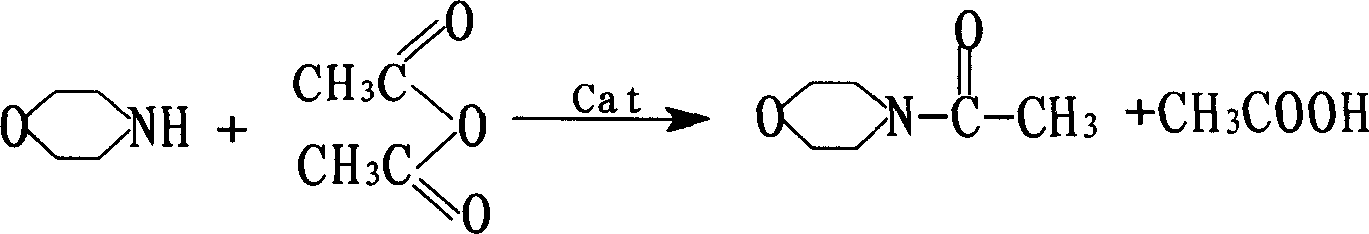

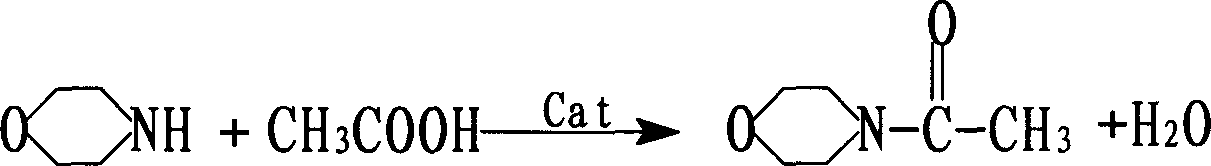

Method used

Image

Examples

Embodiment 1

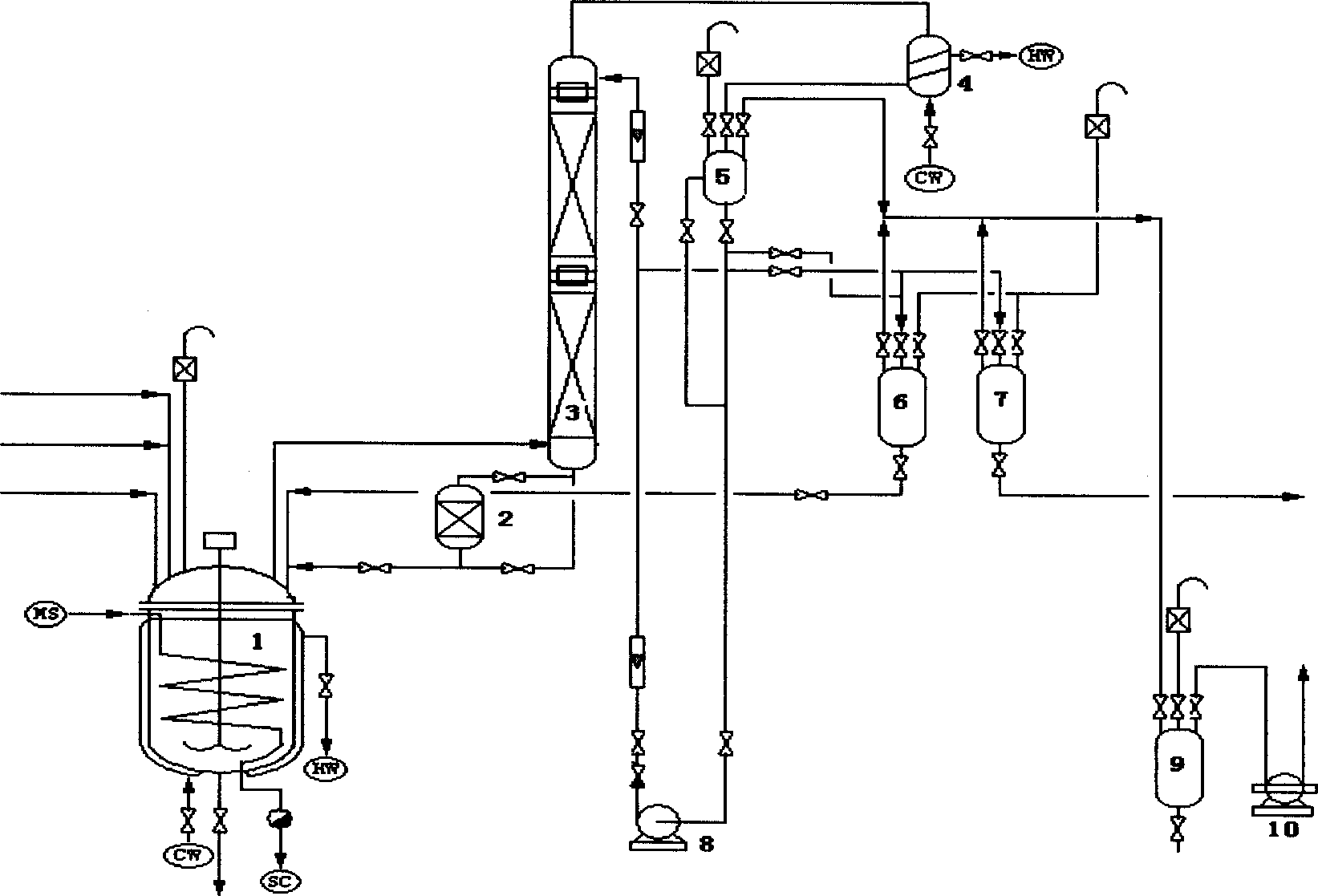

[0046]This embodiment is the specific implementation of the process flow of the present invention. Morpholine (when the recovery liquid is recycled, the amount of morpholine is reduced by 4%), acetic anhydride, toluene (when the recovery liquid is recycled, the amount of toluene is reduced by 95%) are injected into the morpholine metering tank, In the acetic anhydride metering tank and the toluene metering tank (not listed in the figure), put the molecular sieve catalyst (powder) into the stirred tank reactor (1), add morpholine and toluene successively in the reactor, start stirring, heat up. When the temperature in the kettle reaches 110°C, start to add acetic anhydride slowly (the feeding rate is based on the principle that no liquid flooding occurs in the batch reaction rectification tower), and stop heating at the same time. It rises and gasification occurs, and when the acetic anhydride is added, the heating is resumed. The gas phase of the reactor enters the bottom of...

Embodiment 2

[0050] Add 174.2g of morpholine, 8.3g of 98% concentrated sulfuric acid and 41.5g of toluene into a four-neck flask equipped with a stirrer, a thermometer, a constant pressure funnel, a reflux condenser and a water separator, heat until reflux occurs, and stir vigorously and Heat to reflux, under the condition of reflux temperature of 70-74°C, slowly add 102.1g of acetic anhydride dropwise, morpholine: acetic anhydride = 2.1:1, the time of feeding and heating to reflux is 1.5 hours, condense and reflux for 2 hours to divide the water, when the water is divided Stop the reaction when water no longer occurs in the vessel, and the reaction time is 5 hours. Based on morpholine, the conversion rate was 95.1%, and the yield was 91.4%.

example 3

[0052] Add 174.2g morpholine, N-72 strong acid type ion-exchange resin 8.7g and toluene 43.7g in the four-necked flask that is furnished with stirrer, thermometer, constant pressure funnel, reflux condenser and water trap, be heated to reflux occurring, Heat to reflux at slightly boiling or boiling temperature, and slowly add 117.3 g of acetic anhydride dropwise under strong stirring conditions, morpholine: acetic anhydride = 1.8: 1, the time of feeding and heating to reflux is 1.5 hours, condense and reflux for 2 hours to separate water, Stop the reaction when no more water occurs in the water separator, and the reaction time is 5 hours. Based on morpholine, the conversion rate was 98.3%, and the yield was 95.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com