Magnesium columbate microweve medium ceramic and its preparation process

A technology of microwave dielectric ceramics and magnesium niobate, which is applied in the direction of ceramics and inorganic insulators, can solve the problems of impossible preparation of multilayer devices, high cost of microwave ceramic devices, and inability to co-fire, etc., to achieve excellent microwave dielectric properties, easy to The effect of industrial promotion and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Taking the preparation of product 100kg of the present invention as an example, the raw materials used and their weight proportions are:

[0036] Magnesium Niobate 95kg

[0039] Its preparation method is as follows:

[0040] 1. Grinding

[0041] Mix the magnesium niobate material powder with vanadium pentoxide and lithium carbonate evenly, grind into fine powder, and pass through a 150-mesh sieve to make a mixture.

[0042] 2. Granulation

[0043] Add polyvinyl alcohol with a concentration of 5% in the mixture, the addition amount is 2% of the weight of the mixture, fully stir, dry naturally, granulate, and pass through a 60-mesh sieve to make spherical powder.

[0044] 3. Making blanks

[0045] Put the granulated powder into a φ15mm stainless steel mold, and press it into a cylindrical blank with a height of 7.5mm under a pressure of 5,000.

[0046] 4. Sintering

[0047] Put the produced blank into an...

Embodiment 2

[0051] Taking the preparation of product 100kg of the present invention as an example, the raw materials used and their weight proportions are:

[0052] Magnesium Niobate 93.6kg

[0053] Vanadium pentoxide 6.4kg

[0054] The preparation method is as follows: mix magnesium niobate powder with vanadium pentoxide, grind it into fine powder, and pass through a 150-mesh sieve. Put the aluminum crucible into the muffler furnace, heat up continuously, keep warm at 500°C for 1 hour for plastic discharge, continue to heat up, sinter at 1000°C for 3 hours, cool down to 900°C, turn off the power, cool naturally, and come out of the furnace. Other processing steps are identical with embodiment 1.

Embodiment 3

[0056] Taking the preparation of product 100kg of the present invention as an example, the raw materials used and their weight proportions are:

[0057] Magnesium Niobate 99.57kg

[0058] Vanadium pentoxide 0.43kg

[0059] The preparation method is as follows: mix magnesium niobate powder with vanadium pentoxide, grind it into fine powder, and pass through a 150-mesh sieve. Put the aluminum crucible in the muffler furnace, heat up continuously, keep warm at 500°C for 1 hour to discharge the plastic, continue to heat up, sinter at 1050°C for 2 hours, cool down to 900°C, turn off the power, cool naturally, and come out of the furnace. Other processing steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

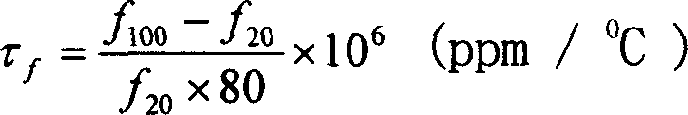

| Qf | aaaaa | aaaaa |

| Temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com