Method for preparing polymer of electric field tuning/2D optical grating in liquid crystal

A two-dimensional grating and polymer technology, applied in diffraction grating, microlithography exposure equipment, optics, etc., can solve the problems of diffraction efficiency and unadjustable diffraction pattern, and achieve the effect of simple and easy-to-control preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

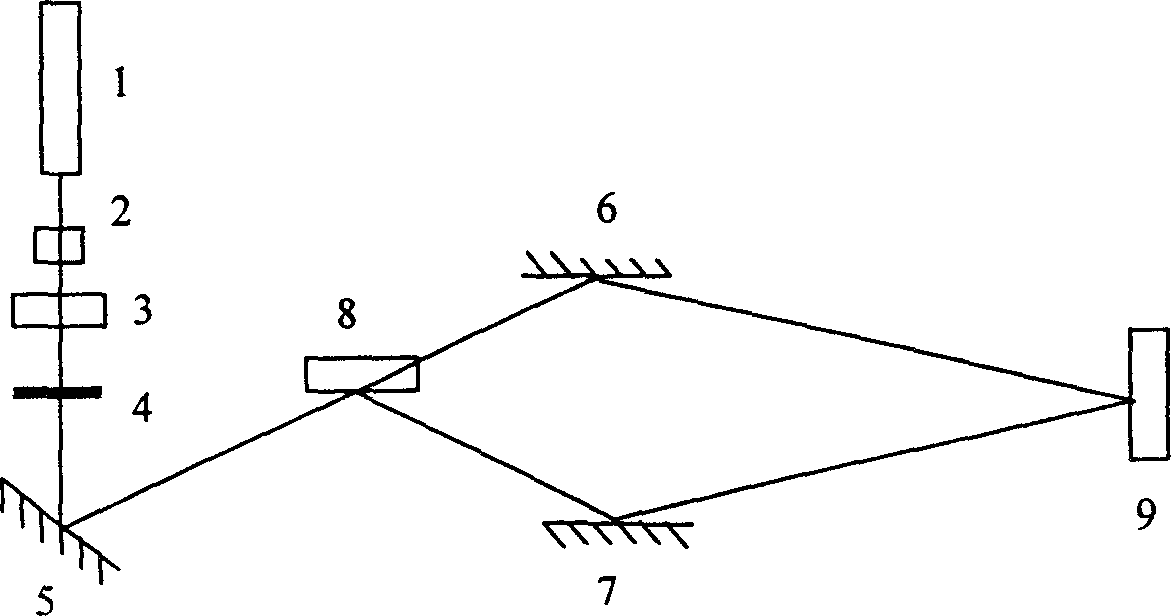

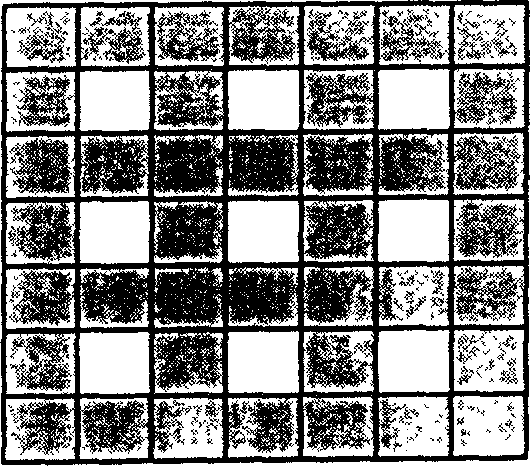

Method used

Image

Examples

Embodiment Construction

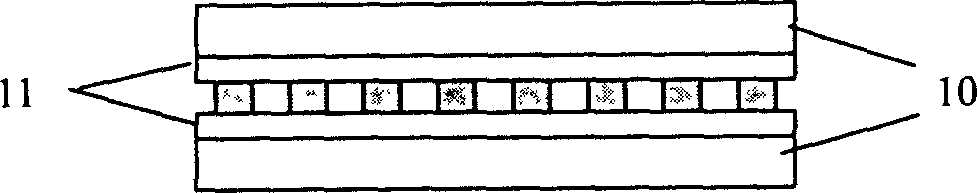

[0027] 1) Preparation of the liquid crystal cell: Cut the glass with a thickness of 0.7mm into two ITO glass substrates with a size of 2×2cm, stack them with ITO as the inner surface, and evenly disperse the spacers with 8 micron diameter glass beads between the two substrates. Fix it with AB glue around it, and leave a liquid injection port to make a liquid crystal cell with a gap of 8 microns.

[0028] 2) Preparation of photosensitive monomer and liquid crystal mixture: select photosensitive monomer NPGDA (Beijing Fontes Chemical Material Co., Ltd.) as 64wt% by weight and mix it in nematic liquid crystal TEB30A (Shijiazhuang Lilike Company), and then add 0.5 wt% initiator Rose Bengal (ACROS ORGNICS) and 1 wt% co-initiator N-phenylglycine (ALDRICH CHENICAL COMPANY) in the total amount of both. A total of 3 g of the prepared mixture was prepared. The mixture was heated to the liquid crystal clearing point of 70°C, then removed from the heater, placed on a magnetic stirrer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com