Process for manufacturing photosensitive flat-panel with Se allotropic P.N or N.P structure

A manufacturing process and technology for large flat plates, applied in the field of manufacturing process of large photosensitive flat plates, can solve the problems of the popularization, development and improvement of DR technology, difficulty in obtaining film layers, and runaway temperature of conductive flat plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

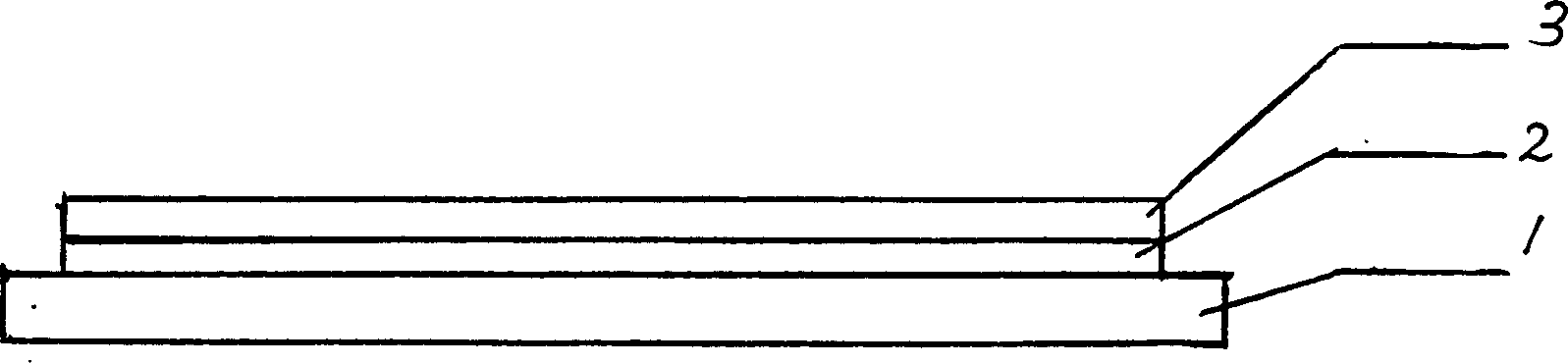

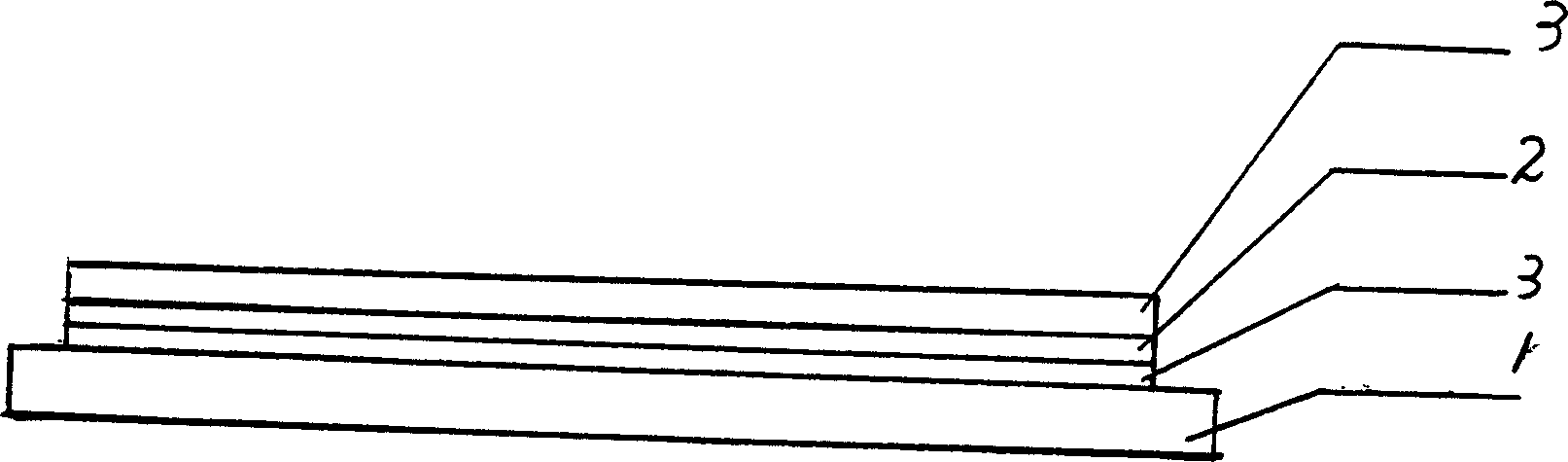

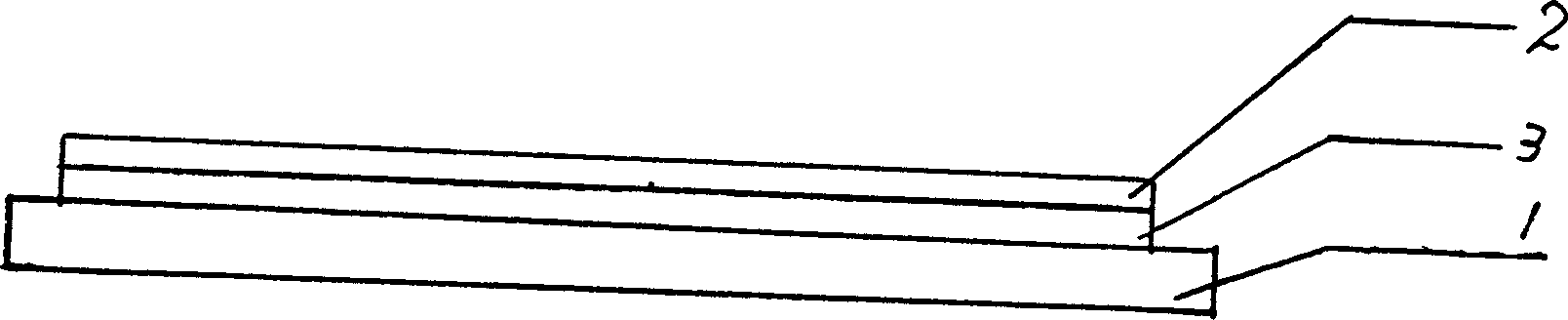

Image

Examples

Embodiment Construction

[0019] The requirements of this process for vacuum coating equipment:

[0020] 1. The vacuum degree is at 10 -3 ~10 -5 Pa.

[0021] 2. Evaporation boat material and heating method: ①. It can be heated by an aluminum-magnesium alloy boat electric furnace ②. Use a stainless steel boat and short-circuit heating.

[0022] 3. The evaporation boat must have a baffle.

[0023] 4. Temperature control substrate material: silver, red copper, aluminum plate and the same material type pipe plate welding.

[0024] 5. Temperature control method: Two temperature-controlled water baths control two kinds of temperature circulating water to enter the temperature-controlled substrate

[0025] 6. The evaporation method of the evaporation boat: ①. Dynamic cycle ②. Orientation

[0026] Process steps:

[0027] (a): First clean and dry the conductive plate (conductive plate can be metal plate, glass conductive plate, TFT plate, CMOS plate).

[0028] (b): Put in a vacuum chamber, add heat-condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com